A method for co-producing cellobiase and chitin

A technology of cellobiase and chitin, applied in the field of bioengineering, can solve the problem that cellobiase and chitin cannot be obtained at the same time, achieve the effects of enriching product varieties, sharing production costs, and reducing the pressure of environmental protection treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Prepare basal medium, glucose 10g / L, cellulose powder 20g / L, peptone 10g / L, potassium dihydrogen phosphate 1g / L, magnesium sulfate 0.2g / L, pH5.0, in a 10L fermenter at 121-126 Sterilize at ℃ for 30min.

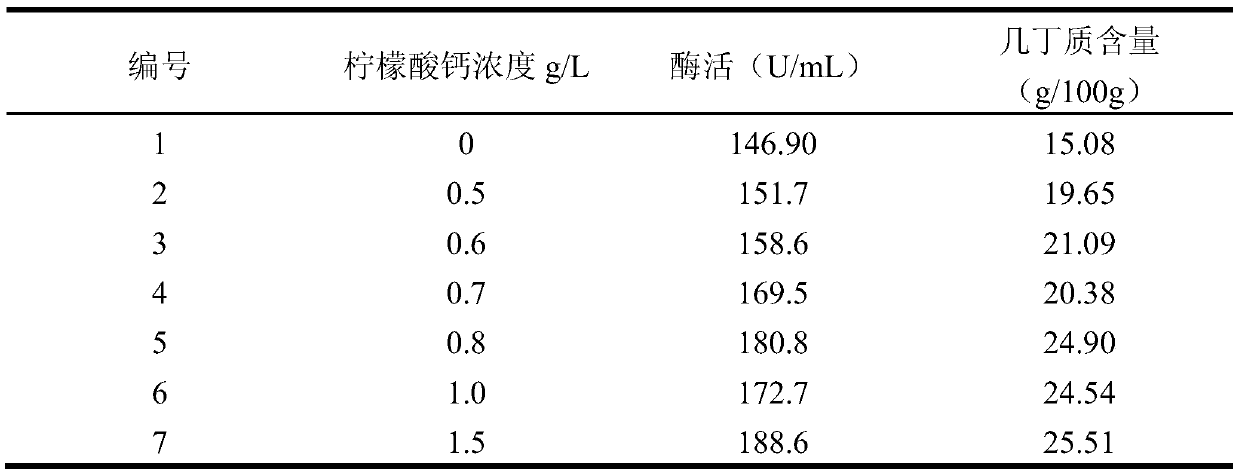

[0034] Add calcium citrate of different concentrations in the basal medium, inoculate Aspergillus niger with 10% inoculum size (v / v) again, carry out fermentation in the fermentor, the fermentor medium filling capacity is 7L, and fermentation condition is: Temperature 30°C (automatic control), pH 5.0 (automatic control by feeding 20% ammonia solution), stirring speed 350r / min, air flow 18L / min, tank pressure 0.04MPa.

[0035] In this example, the Aspergillus niger used was the Aspergillus niger purchased from China General Microorganism Culture Collection Center with the preservation number CGMCC NO.3.11447.

[0036] After the fermentation is completed, pass the fermented liquid through a 0.2 μm microfiltration membrane, the permeated liquid is the cellobiose enzyme ...

Embodiment 2

[0043] Prepare basal medium, glucose 10g / L, cellulose powder 20g / L, peptone 10g / L, potassium dihydrogen phosphate 1g / L, magnesium sulfate 0.2g / L, pH 5.0, in a 10L fermenter at 121-126°C Sterilize for 30min.

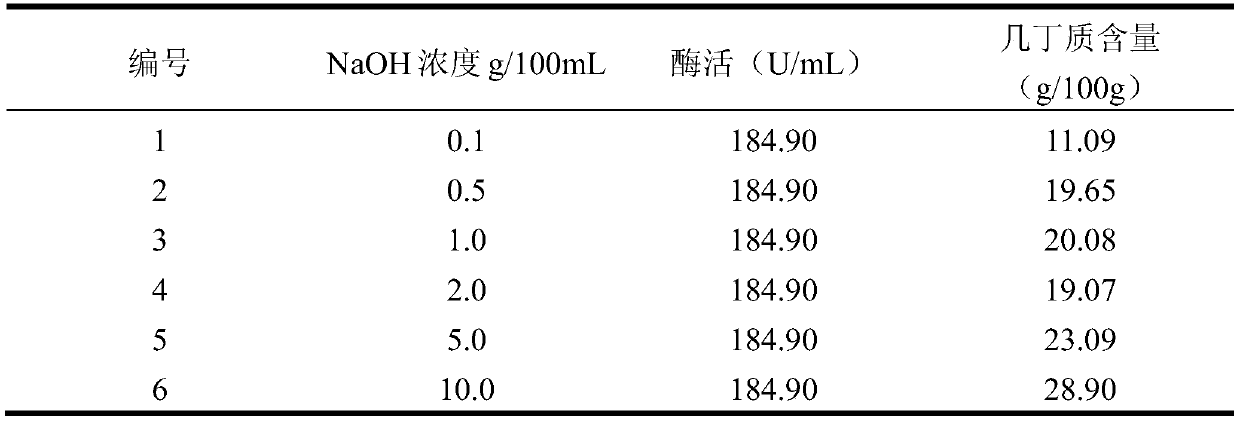

[0044] Add 1.5% calcium citrate in the basal medium, inoculate Aspergillus niger with 10% inoculum size (v / v) again, carry out fermentation in fermenter, fermentation condition is: temperature 30 ℃ (self-control), pH 5.0 ( With 20% ammonia solution feeding automatic control), the stirring speed is 350r / min, the ventilation rate is 18L / min, and the tank pressure is 0.04MPa.

[0045] In this example, the Aspergillus niger used was the Aspergillus niger purchased from China General Microorganism Culture Collection Center with the preservation number CGMCC NO.3.11447.

[0046] After the fermentation is completed, the fermentation liquid is passed through a 0.2 μm microfiltration membrane, and the permeated liquid is the cellobiase liquid, and the retentate is separated from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com