LTCC substrate structure and laser processing method thereof

A laser processing method and substrate technology, which are applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems of high integration, many layers, and high device operating power density, achieve balanced stress, reduce thickness, and achieve flexibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

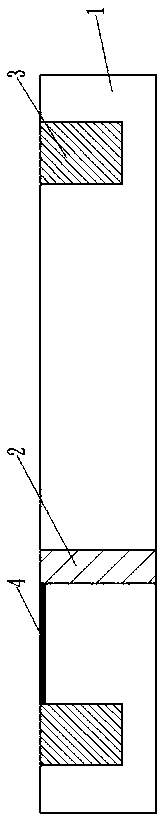

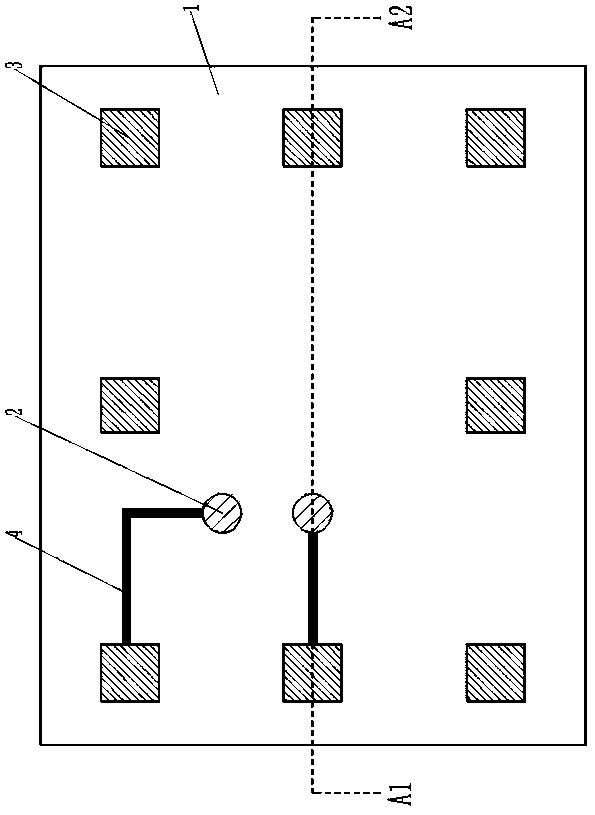

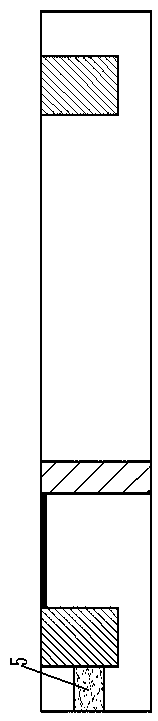

[0018] see figure 1 and 2 ,in figure 1 for along figure 2 The cross-sectional view of the A1A2 line, the LTCC substrate structure of the present invention is formed by stacking a plurality of ceramic sheets 1, each of the plurality of ceramic sheets has opposite first surfaces and second surfaces, and on the first surface and multiple sides between the second surface; the material of the ceramic sheet can be selected from materials commonly used in this field, such as alumina, aluminum nitride, etc., and ceramic materials with better heat dissipation are usually selected.

[0019] Laser etching a first depression and a second depression on the first surface of each of the plurality of ceramic sheets 1, and filling the first depression and the second depression with a conductive substance to form a plurality of blind holes 3 and a plurality of through holes 2; wherein, the plurality of blind holes 3 are formed in the peripheral area of the ceramic sheet 1 and surround t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com