High-efficiency corrosion inhibiting bactericide for oilfield water flooding

An oilfield water injection and fungicide technology, applied in biocides, disinfectants, animal repellents, etc., can solve problems such as damage to water injection pipelines and other equipment, achieve low cost, obvious application effects, and reduce investment and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

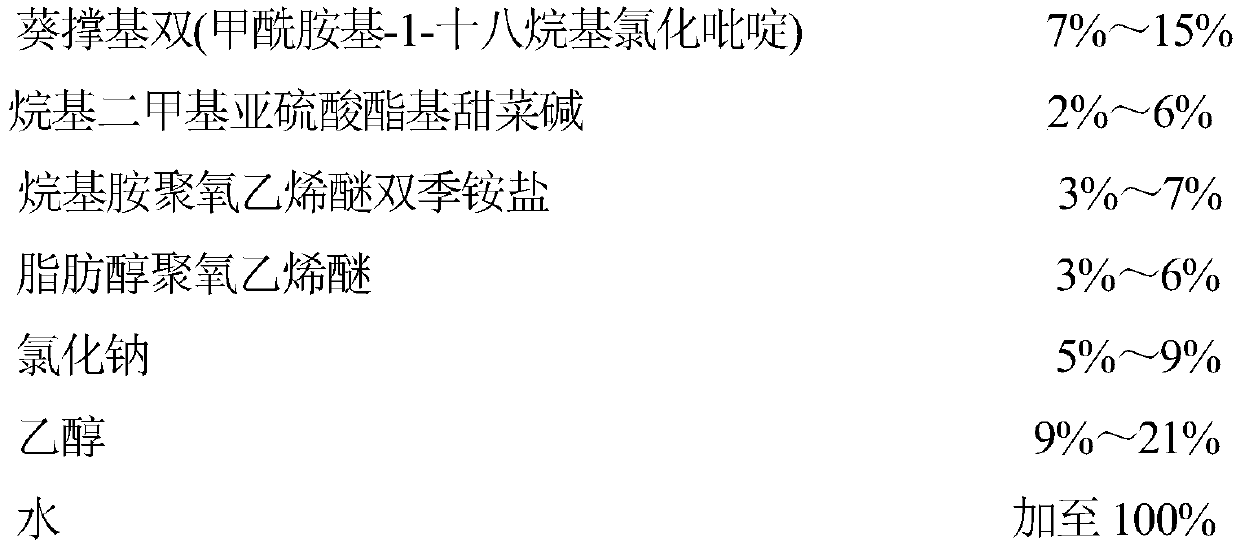

[0030] Taking the preparation of 1 kg of efficient corrosion inhibitor bactericide for oilfield water injection of the present invention as an example, it is made from the raw materials of the following mass proportions:

[0031]

[0032]

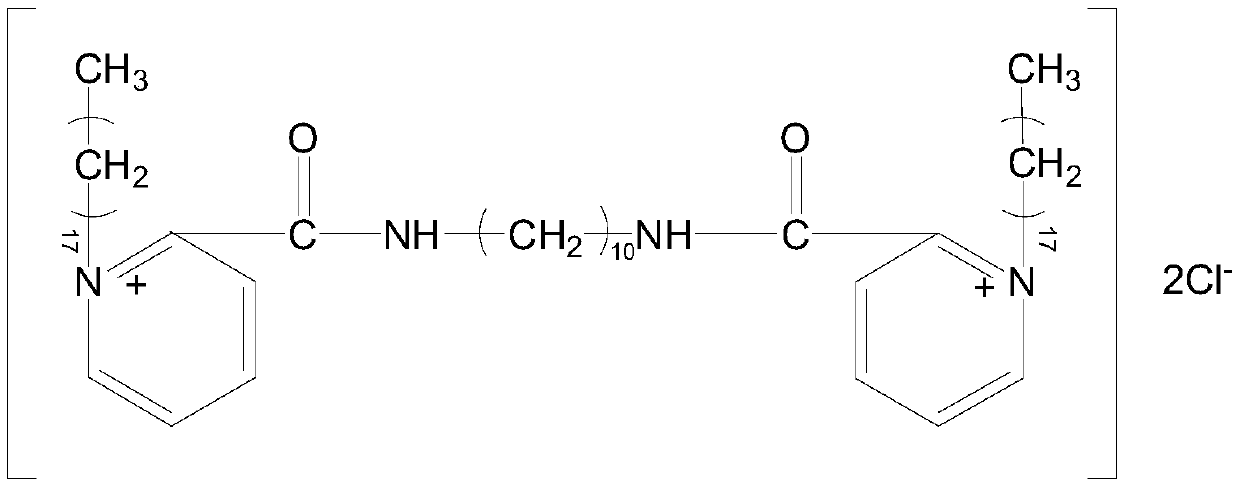

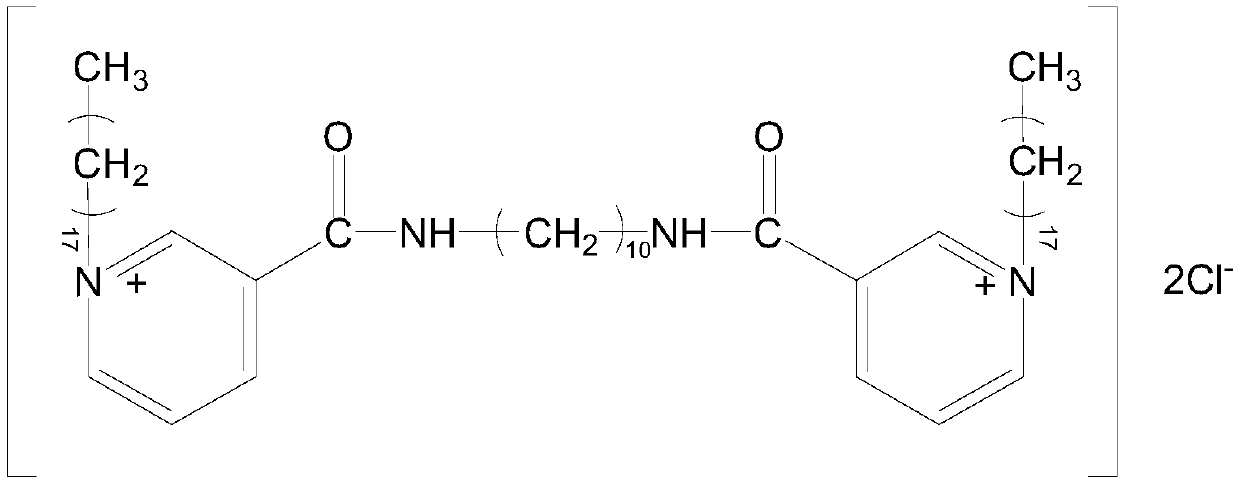

[0033] Its preparation method is: first add 40g of sodium chloride into 660g of water, after completely dissolving, then successively add 40g of fatty alcohol polyoxyethylene ether, 100g of ethanol, 30g of dodecyl dimethyl sulfite betaine, 40g of decane Dialkylamine polyoxyethylene ether bisquaternary ammonium salt and 80 g of decyl bis(2-carboxamido-1-octadecylpyridinium chloride) were added thereinto and stirred evenly.

[0034] The molecular formula of fatty alcohol polyoxyethylene ether in the present embodiment is as follows:

[0035]

Embodiment 2

[0037] Taking the preparation of 1 kg of efficient corrosion inhibitor bactericide for oilfield water injection of the present invention as an example, it is made from the raw materials of the following mass proportions:

[0038]

[0039] Its preparation method is identical with embodiment 1.

[0040] The molecular formula of fatty alcohol polyoxyethylene ether in the present embodiment is as follows:

[0041]

Embodiment 3

[0043] Taking the preparation of 1 kg of efficient corrosion inhibitor bactericide for oilfield water injection of the present invention as an example, it is made from the raw materials of the following mass proportions:

[0044]

[0045]

[0046] Its preparation method is identical with embodiment 1.

[0047] The molecular formula of fatty alcohol polyoxyethylene ether in the present embodiment is as follows:

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com