Preparation method for fermented sour and spicy ruditapes variegata sauce with enhanced flavor

A hot and sour clam, flavor enhancement technology, applied in the field of preparation of fermented hot and sour clam sauce, can solve the problems of reducing the nutritional value of clams, high oil content does not meet the concept of healthy diet, etc., to enhance product flavor, improve sensory quality, strengthen The effect of nutritional properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The technical problem to be solved by the present invention is realized by the following technical solutions: a preparation method of fermented hot and sour clam sauce, comprising raw material pretreatment, raw material cutting, mixed material fermentation, canning, sterilization and cooling, specifically comprising the following steps:

[0037] (1) Raw material pretreatment: Add sand-spiked and cleaned clams into water with 3 times the mass and cook at 95-100°C for 10 minutes, take out the clam meat for later use. The clam broth is vacuum-concentrated at a temperature of 70°C and a vacuum degree of -0.08MPa to -0.09MPa to a soluble solid content of 15%wt to obtain clam concentrate juice; remove the skin of the ginger and clean it, and remove the garlic Peel off the outer skin and clean, and clean the king oyster mushrooms and fresh peppers.

[0038] (2) Raw material cutting: 1.5kg of ginger and 1.5kg of garlic are mixed together and twisted into ginger and garlic mash ...

Embodiment 2

[0044]The technical problem to be solved by the present invention is realized by the following technical solutions: a preparation method of fermented hot and sour clam sauce, comprising raw material pretreatment, raw material cutting, mixed material fermentation, canning, sterilization and cooling, specifically comprising the following steps:

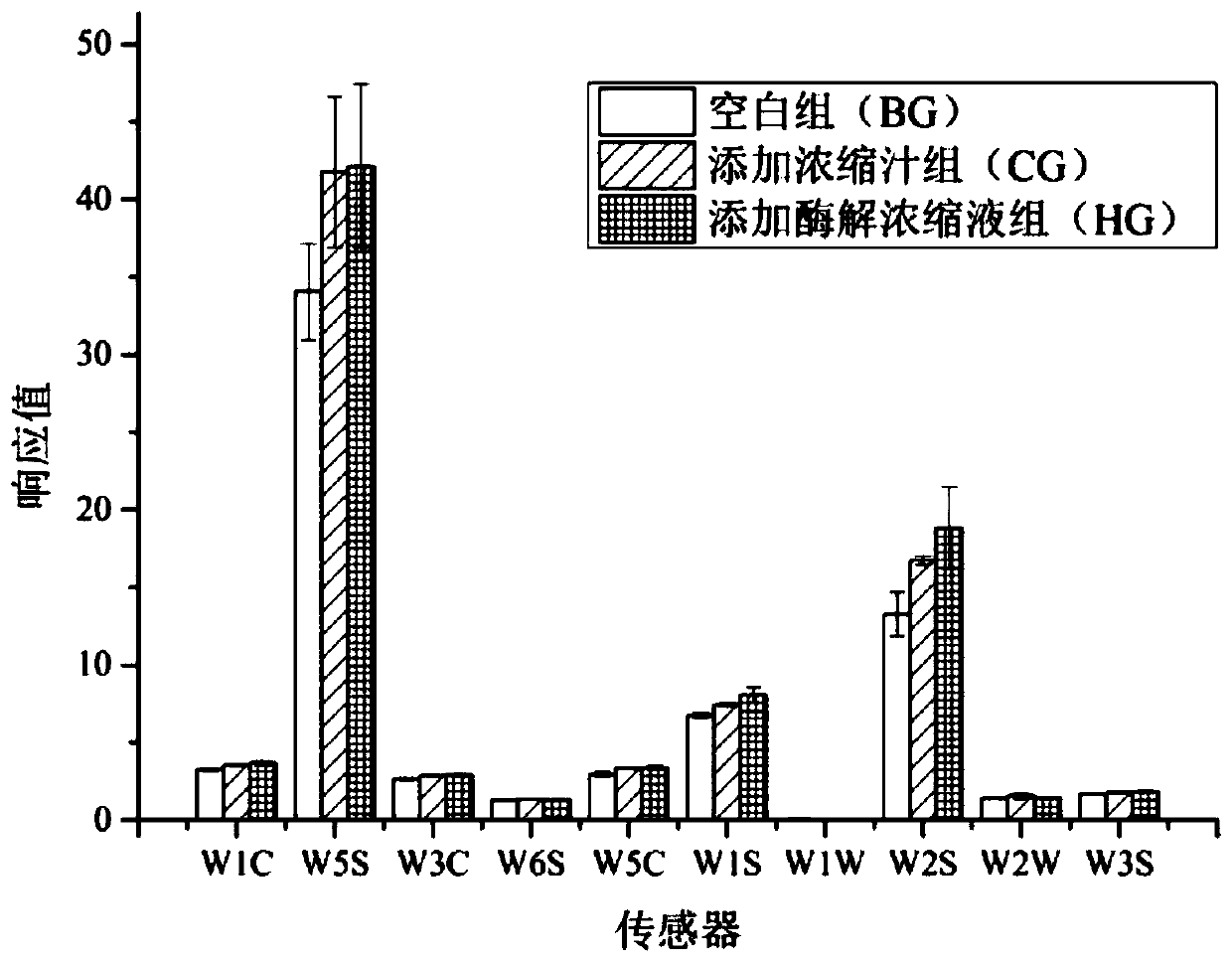

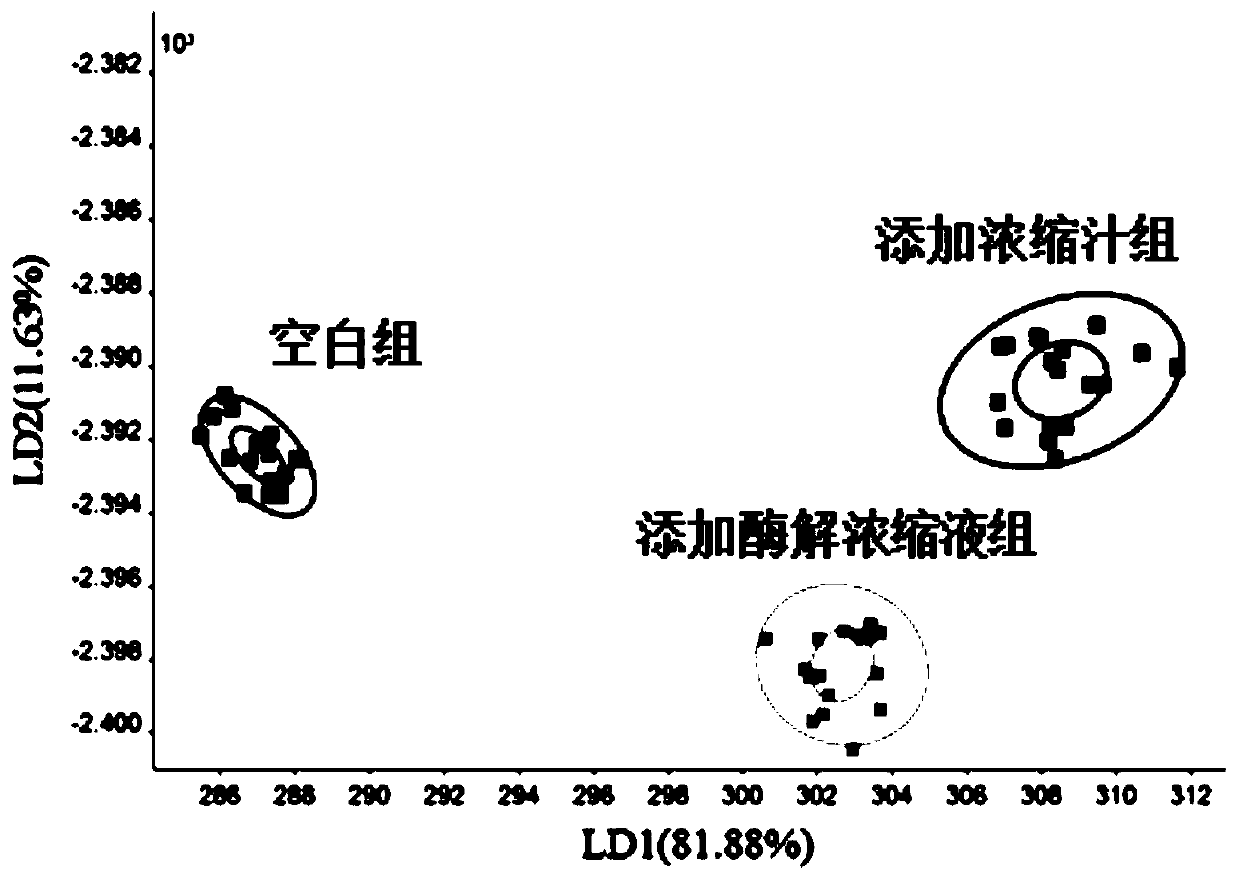

[0045] (1) Preparation of clam enzymatic hydrolysis concentrate: Peel the clams that spit out sand and clean to get raw clam meat, add water (raw clam meat to water weight ratio 1:2) and heat up to 95°C, then immediately cool down to 58°C 1. Take clam meat and broth, add Novozymes compound protease accounting for 0.2% of raw clam meat mass and Novozymes flavored protease accounting for 0.2% of raw clam meat mass, enzymolyze at 58°C for 2.5 hours, after enzymatic hydrolysis Heat up to 95-100°C to inactivate the enzyme for 20 minutes, filter the enzymolysis solution with 300 mesh, and vacuum concentrate it to a soluble solid content of 15%...

Embodiment 3

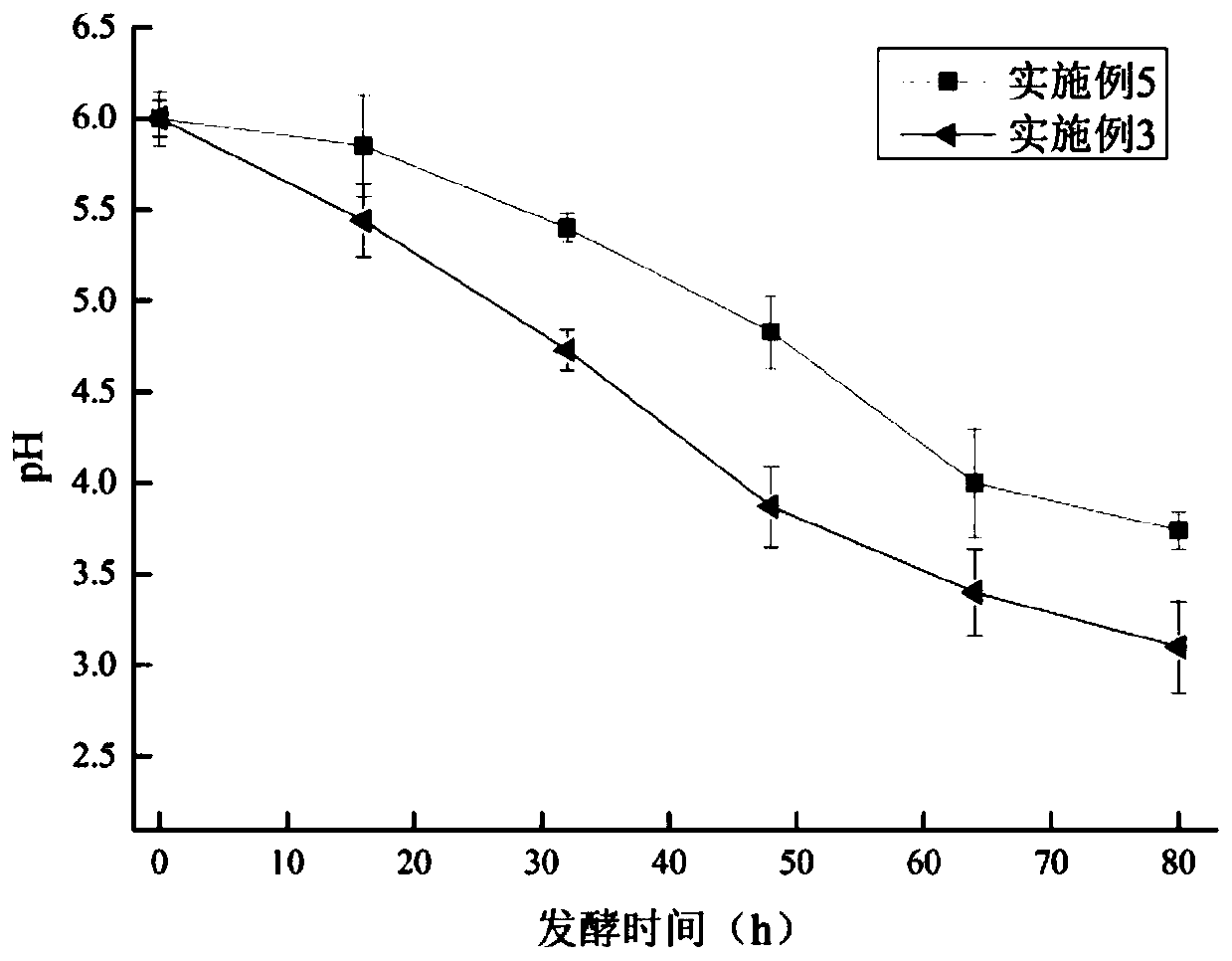

[0102] The technical problem to be solved by the present invention is realized by the following technical solutions: a preparation method of fermented hot and sour clam sauce, comprising raw material pretreatment, raw material cutting, mixed material fermentation, canning, sterilization and cooling, specifically comprising the following steps:

[0103] (1) Preparation of clam enzymatic hydrolysis concentrate: Peel the clams that spit out sand and clean to obtain raw clam meat, add water of the same quality as the raw clam meat, heat up to 95°C and cook for 10 minutes, then immediately cool down to 55°C, take Add Novozymes compound protease accounting for 0.2% of the mass of raw clam meat and Novozymes flavored protease accounting for 0.2% of the mass of raw clam meat to the clam meat and broth, and perform enzymatic hydrolysis at 55°C for 2 hours, and heat up to Inactivate the enzyme at 95-100°C for 10 minutes, filter the enzymolysis solution with 300 meshes, and concentrate it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com