Preparation method of highly-anti-fouling polyvinylidene fluoride (PVDF) porous base composite ultrafiltration membrane material

A polyvinylidene fluoride and ultrafiltration membrane technology, which is applied in ultrafiltration, chemical instruments and methods, and membranes, can solve the problems of easy pollution and low flux of membrane materials, and achieve easy operation, low production cost, and extended use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The embodiment of the present disclosure discloses a preparation method of a polyvinylidene fluoride porous-based composite ultrafiltration membrane material. The preparation method specifically includes the following steps:

[0031] S1) Soak the PVDF membrane in an aqueous solution containing diamino molecular solutes, and set aside;

[0032] S2) adding the transition metal to the aqueous solution containing diamino molecular solute soaked in PVDF membrane prepared in S1), ultrasonically dispersing, and then adding the organic solution containing organic ligands;

[0033] S3) Control the reaction temperature and reaction time; finally, the membrane material is taken out, washed and dried to obtain a polyvinylidene fluoride porous-based composite ultrafiltration membrane material.

[0034] According to an embodiment of the present disclosure, the concentration of the aqueous solution of the diamino molecule solute in S1 is 10% to 40%; the diamino molecule is ethylenedia...

Embodiment example 1

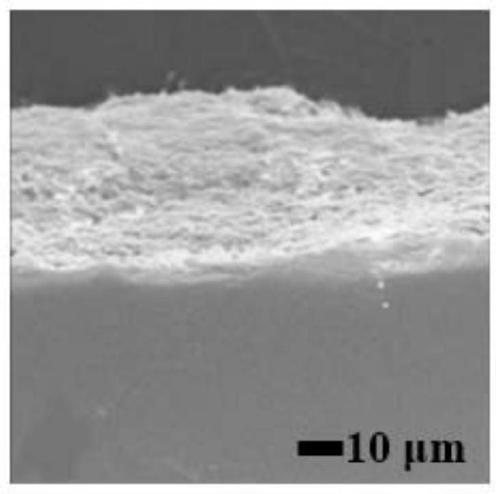

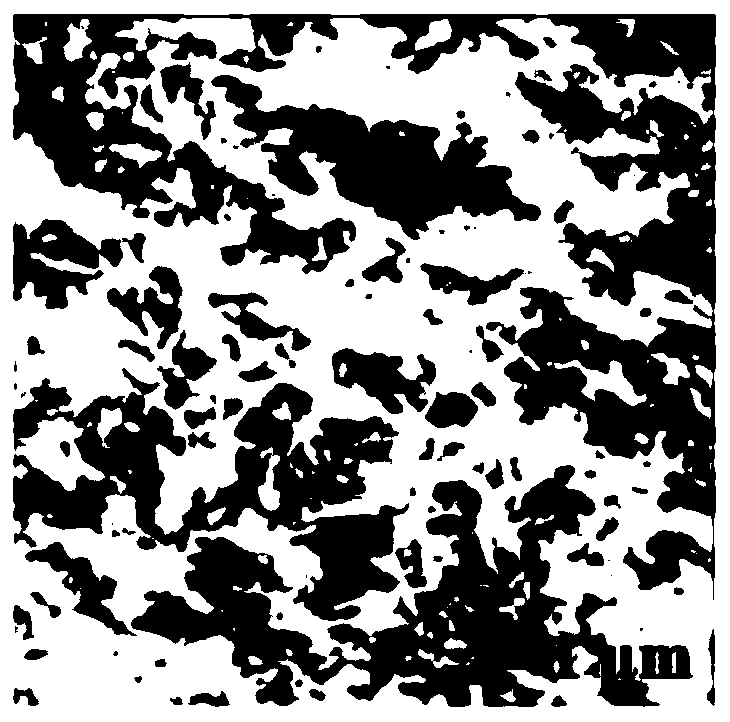

[0044]1) Soak the PVDF membrane in 5 mL of ethylenediamine aqueous solution with a volume concentration of 10% for 2 h, add 2.3 mmol of zinc nitrate tetrahydrate, ultrasonically disperse at 60 kHz for 20 min, and dissolve 0.8 mmol of 2-aminoterephthalic acid In 10 mL of anhydrous N,N dimethylformamide (DMF), pour it into the PVDF membrane reaction solution, ultrasonically disperse for 30 min, and react in an oven at 100 °C for 20 h. Wash with methanol three times, and then dry in an oven at 50 °C for 5 h to obtain PVDF / IRMOF-3 composite ultrafiltration membrane material.

[0045] 2) The prepared PVDF / IRMOF-3 composite ultrafiltration membrane was tested for antifouling performance and tensile strength.

Embodiment example 2

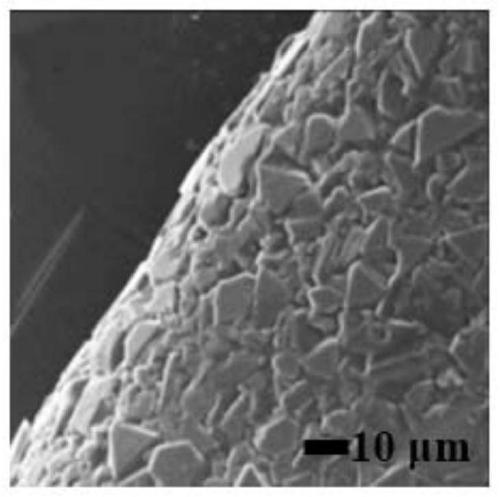

[0047] 1) Soak the PVDF membrane in 5 mL of p-phenylenediamine aqueous solution with a volume concentration of 25% for 2 h, add 4.0 mmol of copper nitrate trihydrate, disperse with 40 kHz ultrasonic for 60 min, and dissolve 2.0 mmol of m-tribenzoic acid in 12 mL of deionized water / ethanol (v:v=1:1) mixed solution, and poured into the PVDF membrane reaction solution, ultrasonically dispersed for 30 min, and reacted in a 60 °C oven for 15 h, and the membrane was taken out after natural cooling, and used The PVDF / CuBTC composite ultrafiltration membrane material was obtained by washing with deionized water and methanol five times, and then drying in an oven at 40 °C for 6 h.

[0048] 2) The antifouling performance test and tensile strength test were carried out on the prepared PVDF / CuBTC composite ultrafiltration membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com