A laser drilling device and method for improving hole quality based on underwater drilling

An underwater laser and laser drilling technology, which is applied to laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of poor versatility of directional chemical etching, high cost of femtosecond lasers, and high processing conditions, and achieve improvement. The roundness of the forming hole is poor, the phenomenon of micro-cracks is improved, and the effect of reducing the recasting layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better illustrate the implementation details of the present invention, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

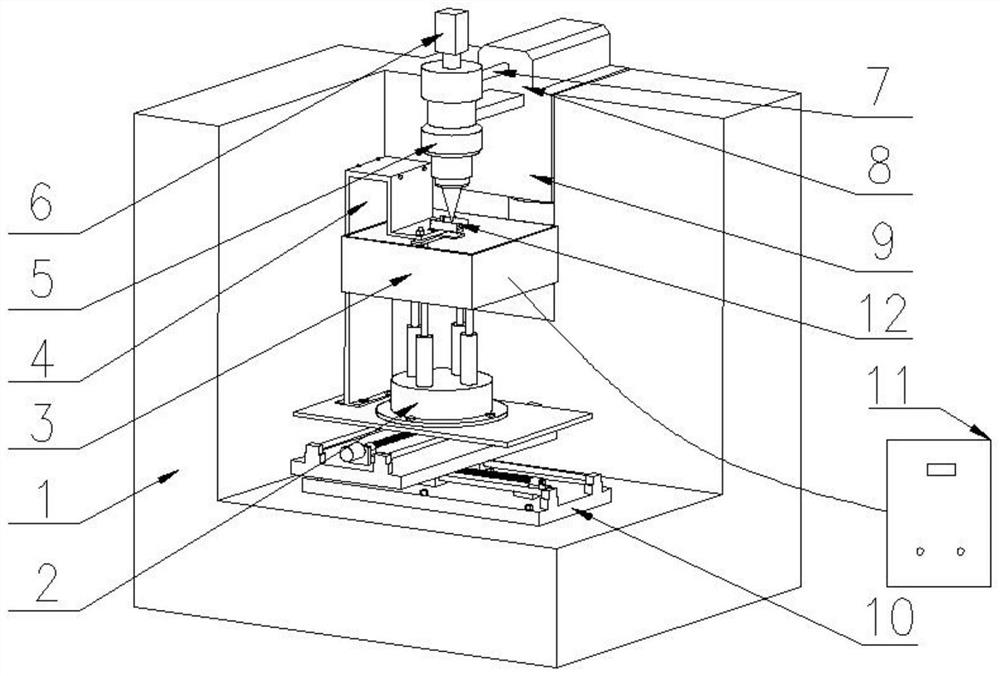

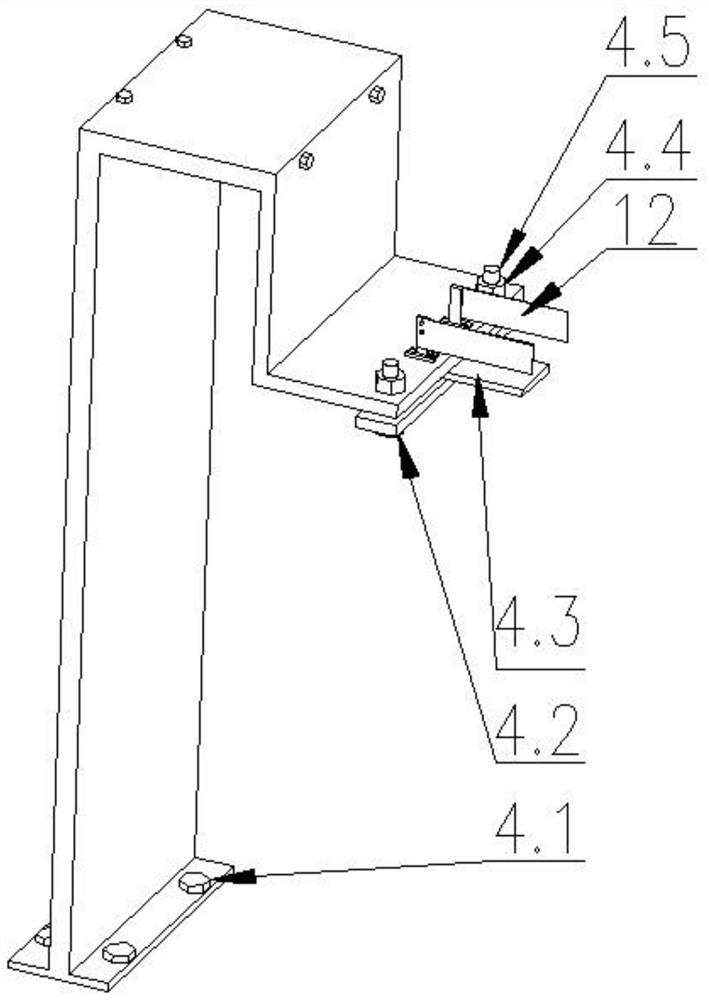

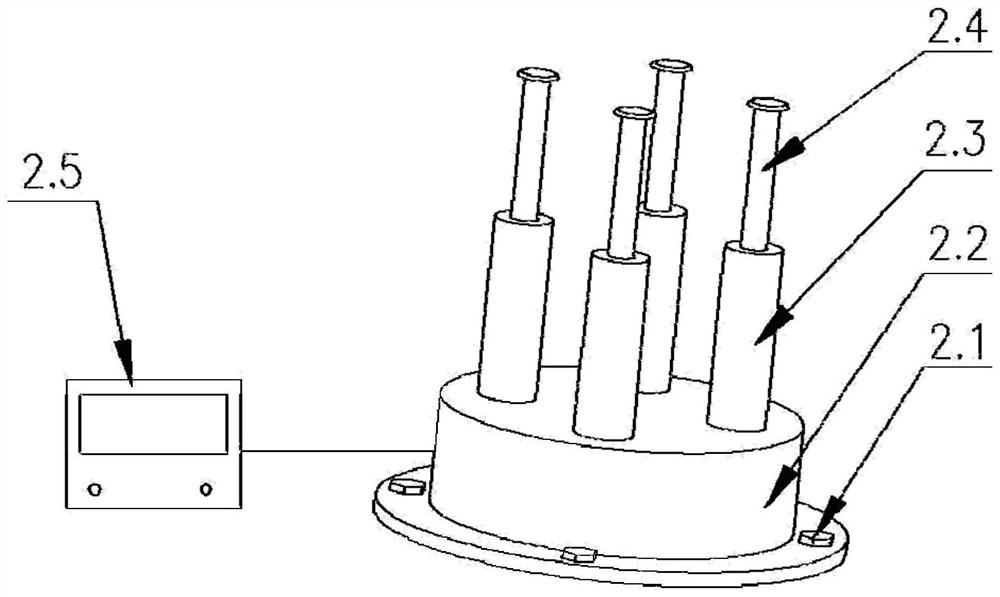

[0035] combined with figure 1 , a laser drilling device for improving hole taper and inner wall quality, characterized in that it includes a power supply box 1, an electric push rod 2, a cuboid container without a cover 3, a workpiece fixture 4, a laser head 5, a CCD camera 6, and a light guide tube 7. Laser 8, z-direction moving mechanism 9, x-y moving platform 10;

[0036] Described power box 1 is installed on the left side vertical surface of machine tool base, and x-y mobile platform 10 is installed on the base upper surface of machine tool, and electric push rod 2 and workpiece fixture 4 are installed on described x-y mobile platform 10, and described electric A cuboid container 3 without a cover is installed on the push rod 2, a z-direction moving mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com