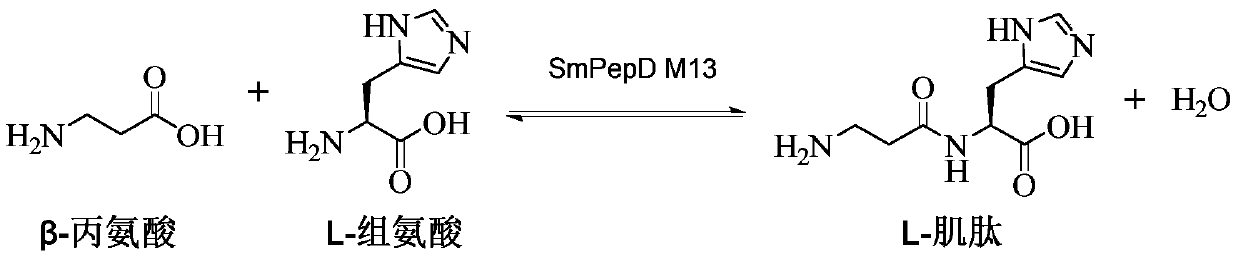

Method for synthesizing L-carnosine by using microorganism enzyme method

A microbial enzyme and carnosine technology, applied in the field of carnosine preparation, can solve the problems of reducing the biocatalytic efficiency of microbial cells, excessive damage to the biological enzyme cell membrane, loss of microbial intracellular substances, etc., to improve the reaction conversion rate, low cytotoxicity, and enzymatic The effect of improving the reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] In the L-carnosine reaction system that is equipped with a stirring device such as a reaction kettle and adding microbial enzymes, directly add an organic solvent for activating microbial enzyme activity and as a penetrating agent and directly add the same for activating microbial enzymes Active divalent metal ions are reacted for 480min at a stirring speed of 140rpm and a reaction temperature of 40°C in the stirring device. After the reaction is completed, the reaction conversion rate is determined by high-performance liquid chromatography analysis, and the reaction solution is collected and centrifuged. The whole cells obtained by centrifugation can continue to be catalyzed to realize recycling, and 15.1 g / L of L-carnosine can be obtained. In the present embodiment, the L-carnosine reaction system is the L-carnosine basic reaction solution, and the volume percent concentration of the organic solvent in the L-carnosine reaction solution is 0.1% (V / V) , the mol concentr...

Embodiment 2

[0019] In the L-carnosine reaction system that is equipped with a stirring device such as a reaction kettle and adding microbial enzymes, directly add an organic solvent for activating microbial enzyme activity and as a penetrating agent and directly add the same for activating microbial enzymes Active divalent metal ions are reacted for 520min at a stirring speed of 160rpm and a reaction temperature of 35°C in the stirring device. After the reaction is completed, the reaction conversion rate is determined by HPLC analysis, and the reaction solution is collected and centrifuged. The whole cells obtained by centrifugation can continue to be catalyzed to realize recycling and obtain 15.2g / L L-carnosine. In the present embodiment, the L-carnosine reaction system is the L-carnosine basic reaction solution, and the volume percent concentration of the organic solvent in the L-carnosine reaction solution is 1.3% (V / V) , the mol concentration (molar concentration) of described divalen...

Embodiment 3

[0021] In the L-carnosine reaction system that is equipped with a stirring device such as a reaction kettle and adding microbial enzymes, directly add an organic solvent for activating microbial enzyme activity and as a penetrating agent and directly add the same for activating microbial enzymes Active divalent metal ions are reacted for 450min at a stirring speed of 150rpm and a reaction temperature of 38°C in the stirring device. After the reaction is completed, the reaction conversion rate is determined by HPLC analysis, and the reaction solution is collected and centrifuged. The whole cells obtained by centrifugation can continue to be catalyzed to realize recycling and obtain 15.15g / L L-carnosine. In the present embodiment, the L-carnosine reaction system is the L-carnosine basic reaction solution, and the volume percent concentration of the organic solvent in the L-carnosine reaction solution is 2.5% (V / V) , the mol concentration (molar concentration) of described divale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com