Radial plasma jet pulse vacuum arc evaporation source and thin film deposition device

A plasma and pulsed arc technology, applied in the fields of pulsed arc evaporation sources and thin film deposition devices, can solve problems such as low utilization rate of film materials, and achieve the effects of reducing process costs, reducing requirements, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

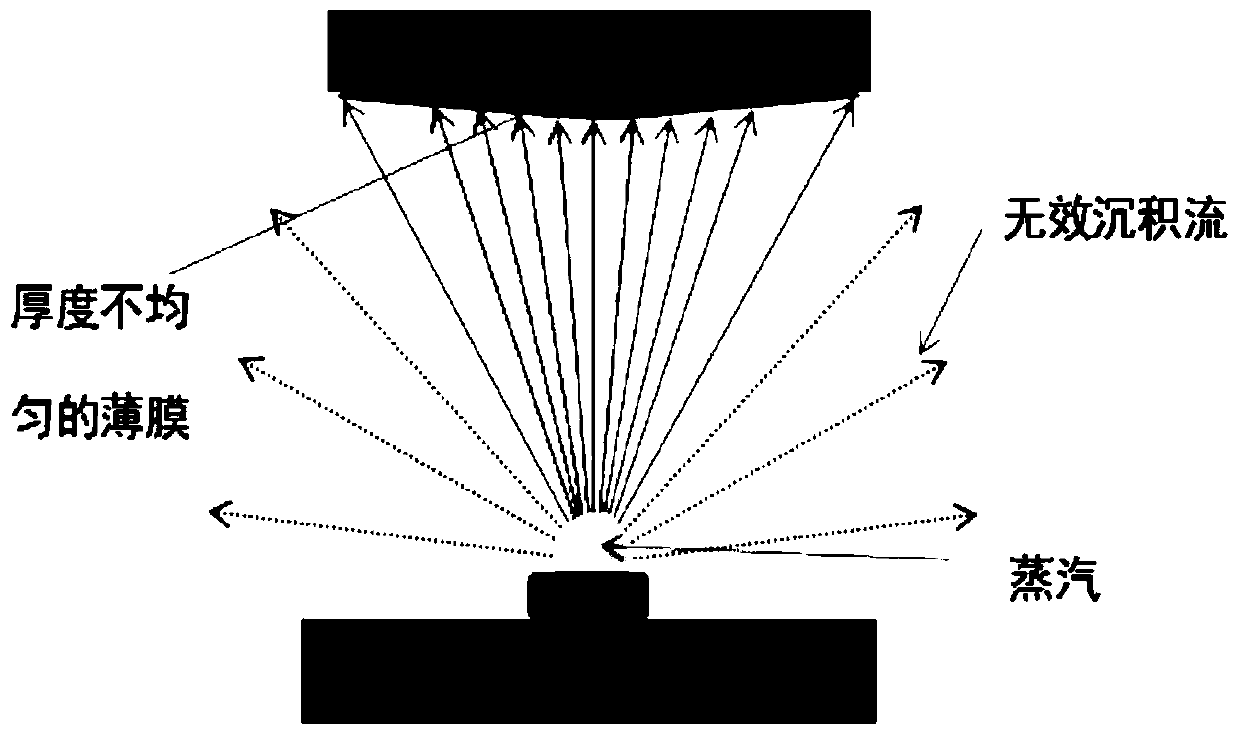

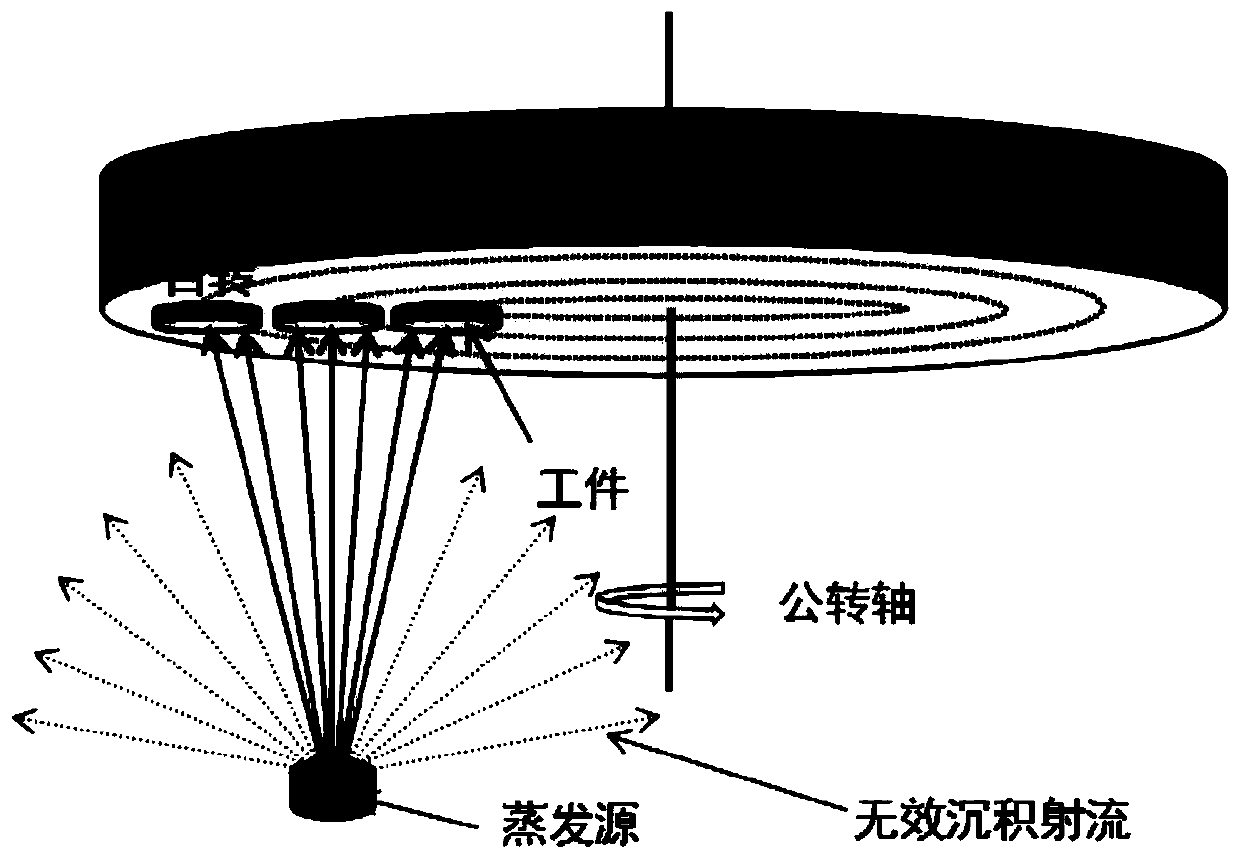

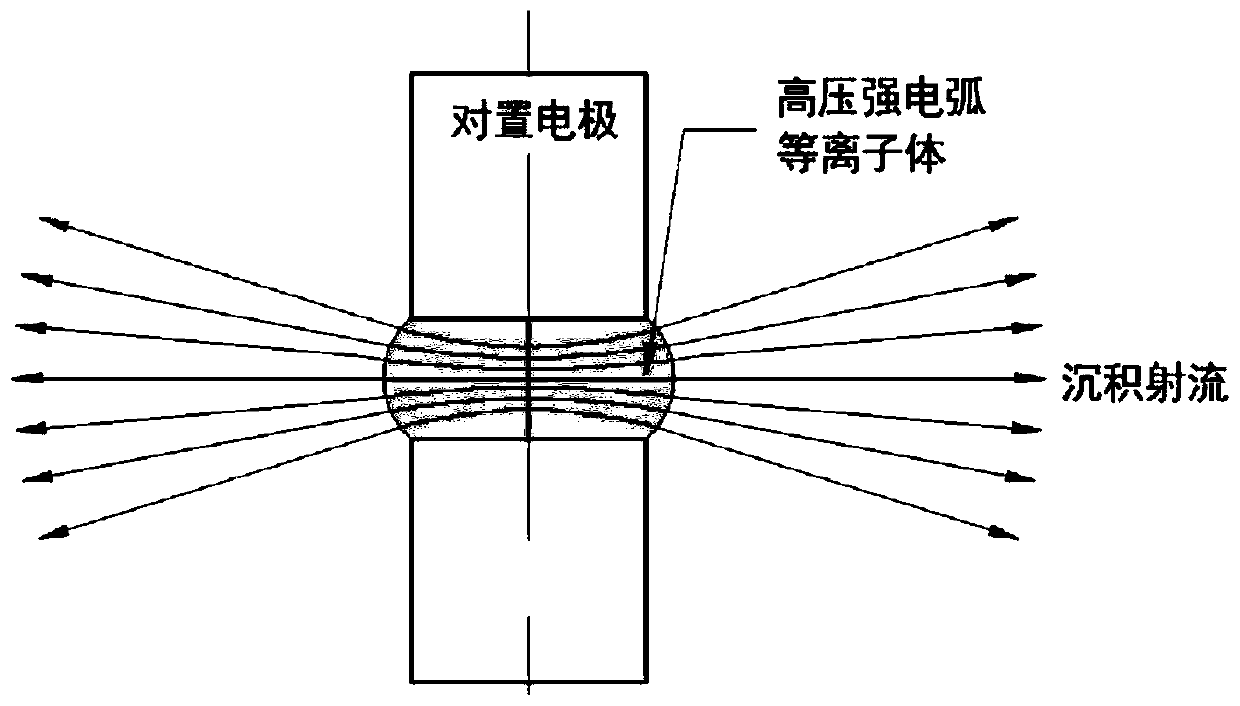

[0028] The core idea of the present invention is to improve the deposition jet itself of the evaporation source so that its distribution can be even. Specifically, the arc plasma is transformed from an inhomogeneous axial cosine-distributed jet to a uniformly distributed radial jet. On this basis, a matching moving workpiece table mechanism is designed to achieve large-area uniform film deposition with high film material utilization.

[0029] The key to realizing the transformation of the above-mentioned deposition jet is to utilize the hydrodynamic characteristics of the high-density pulsed plasma. It is too late to fully expand, and the density and pressure are very high at this stage, which can be regarded as a "continuous fluid". In terms of vacuum technology, the mean free paths of electrons and ions in the plasma under these conditions are very s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com