Open-close type sewage tank sealing cover

A technology for sewage pools and sealing covers, which is applied in the direction of sewage wells, general water supply conservation, waterway systems, etc., and can solve problems such as large labor force, inconvenient opening or covering the sewage pool, and affecting the service life of the covering film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

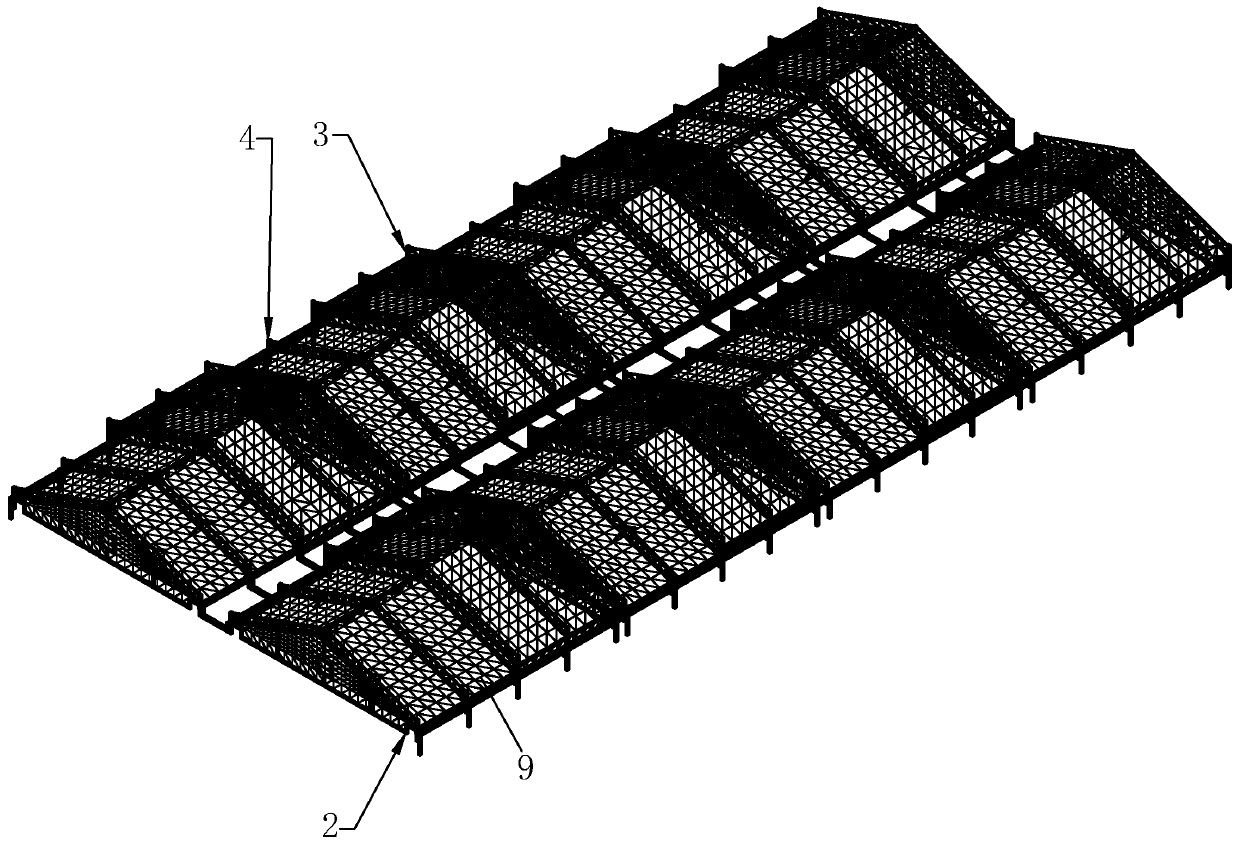

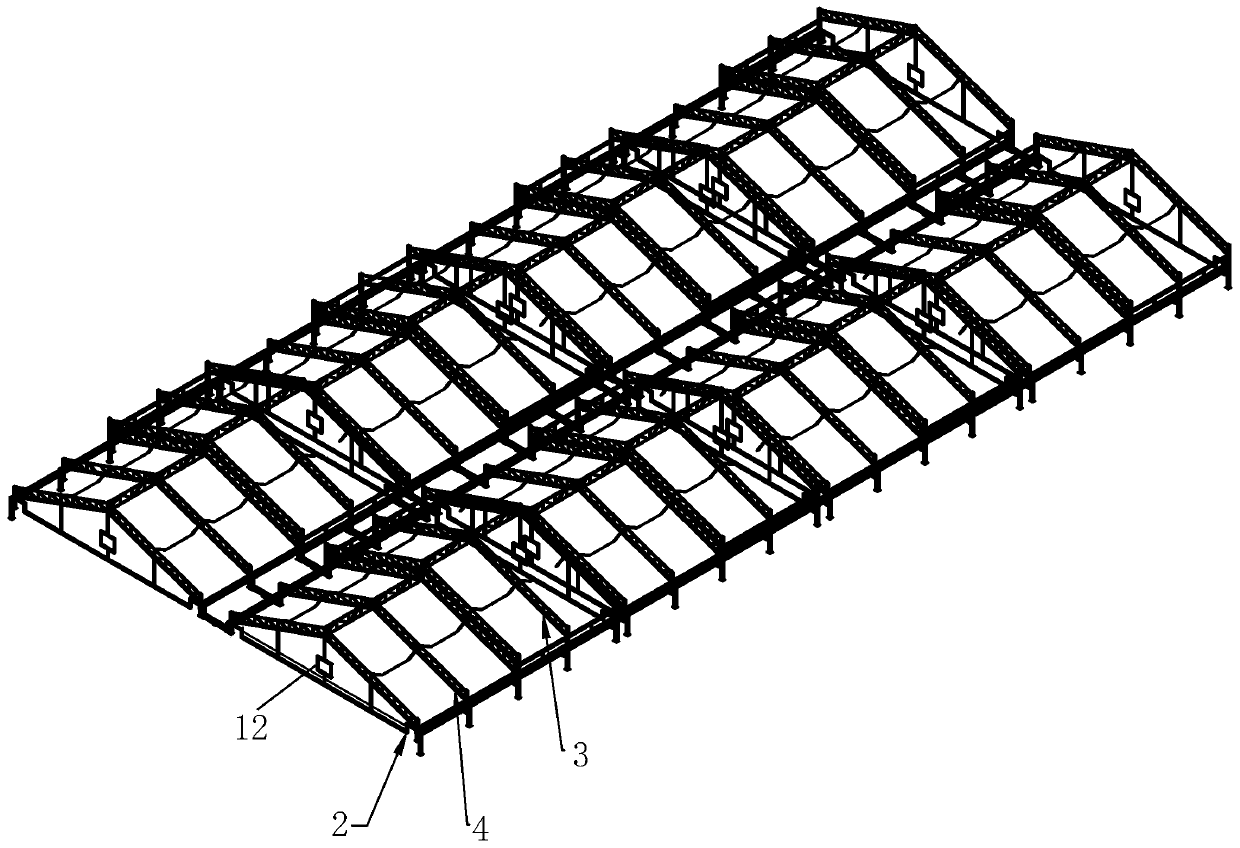

[0067] A kind of sealing cover of opening and closing sewage pool 1, see figure 1 and figure 2 , including a slide rail assembly, a frame assembly and a covering film 9 arranged on the side wall of the sewage pool 1 . In the process of actual sewage treatment, generally there are multiple sewage pools 1 , so there are also multiple sealing covers, and each sealing cover can cover one sewage pool 1 correspondingly. There is enough space between two adjacent sewage pools 1 to place a sealing cover.

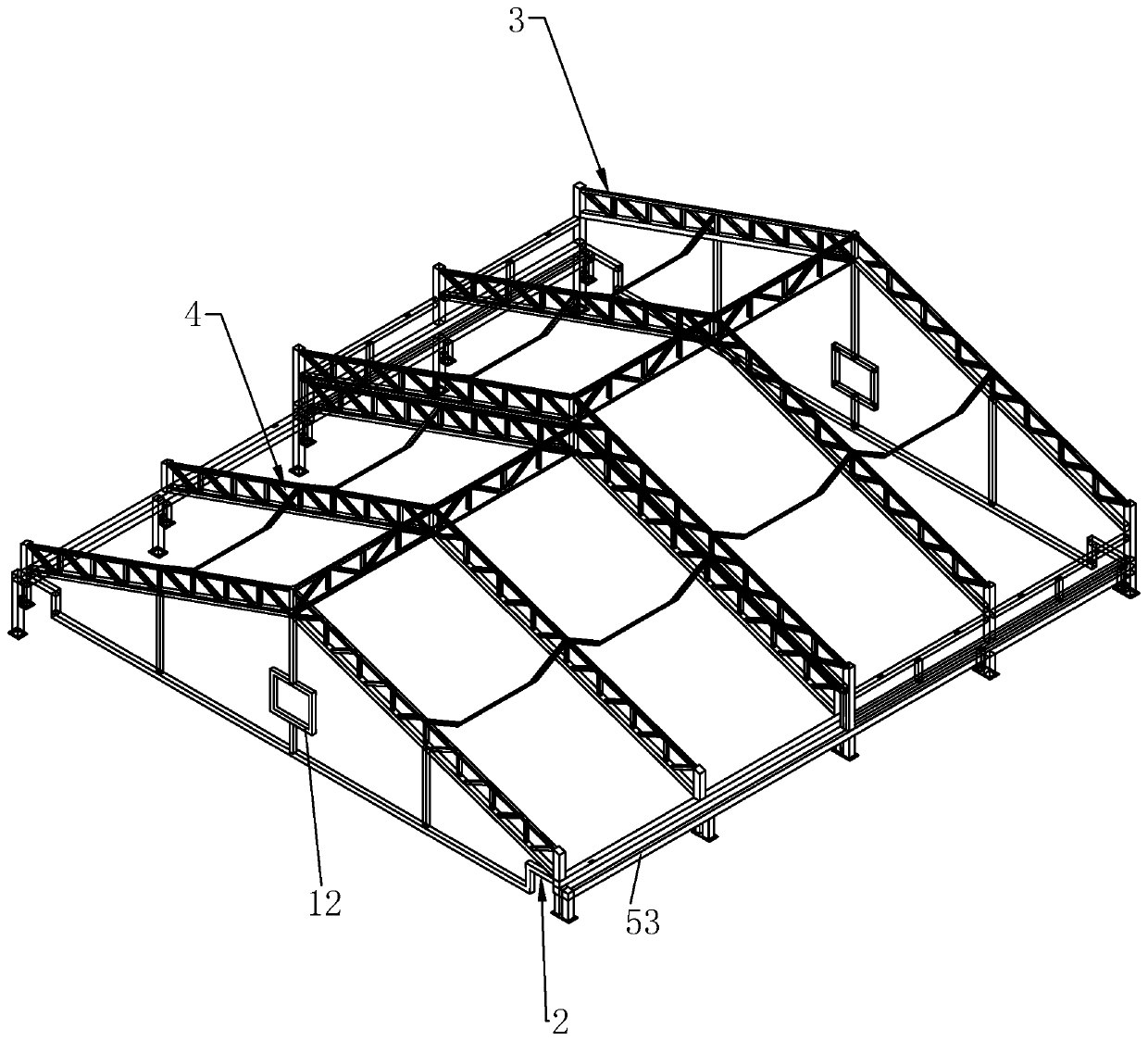

[0068] see image 3 , the frame assembly includes a high frame 3 and a low frame 4, the high frame 3 and the low frame 4 are similar to the gable roof structure, the slope of the high frame 3 and the low frame 4 is generally between 15°-25°, generally in the south In the region, the slope of the high frame 3 and the low frame 4 can be set to 15°; generally in the northern region, the slope of the high frame 3 and the low frame 4 can be set to 25°, which is beneficial to make the...

Embodiment 2

[0090] An open-close sewage pool sealing cover, the difference between this embodiment and Embodiment 1 is:

[0091] The components and parts by mass of the anticorrosion paint covering the film are shown in Table 1.

[0092] Anticorrosion paint is made by following preparation method:

[0093] S1. Weigh and mix epoxy resin, polyurethane resin, ethyl acetate and butyl acetate in corresponding parts by mass, heat to 65° C., and keep warm for 1 hour to obtain mixture B.

[0094] S2. Then add the concave-convex soil in the corresponding mass parts to the mixture B and mix evenly, keep it warm for 0.5h, then lower the temperature to 40°C, add the corresponding mass parts of SAC-100 crosslinking agent while stirring, and stir for 25 minutes. Compound C is obtained.

[0095] S3. Take corresponding parts by mass of deionized water, urea and sodium chloride, mix and stir for 15 minutes to obtain mixture D, and finally mix mixture C and mixture D, and naturally cool to room temperatu...

Embodiment 3

[0100] An open-close sewage pool sealing cover, the difference between this embodiment and Embodiment 1 is:

[0101] The components and parts by mass of the anticorrosion paint covering the film are shown in Table 1.

[0102] Anticorrosion paint is made by following preparation method:

[0103] S1. Weigh the epoxy resin, polyurethane resin, ethyl acetate, and butyl acetate in corresponding parts by mass and mix them evenly, heat to 85° C., and keep the temperature for 2 hours to obtain the mixture B.

[0104] S2. Then add the concave-convex clay of the corresponding mass parts to the mixture B and mix evenly, keep it warm for 1h, then lower the temperature to 50°C, add the corresponding mass parts of SAC-100 cross-linking agent while stirring, and after stirring for 30min, get Mixture C.

[0105] S3. Take corresponding parts by mass of deionized water, urea and sodium chloride, mix and stir for 20 minutes to obtain mixture D, and finally stir and mix mixture C and mixture D,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com