Preparation method of a butterfly-shaped molybdenum-tungsten bimetal composite rotating target

A bimetallic and rotating target technology, which is applied in the field of refractory metal processing, can solve the problems of high delamination tendency of molybdenum base and tungsten layer, affecting product performance, high density, etc., so as to facilitate long-term work and avoid cracking Effects of delamination and improvement of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment includes the following steps:

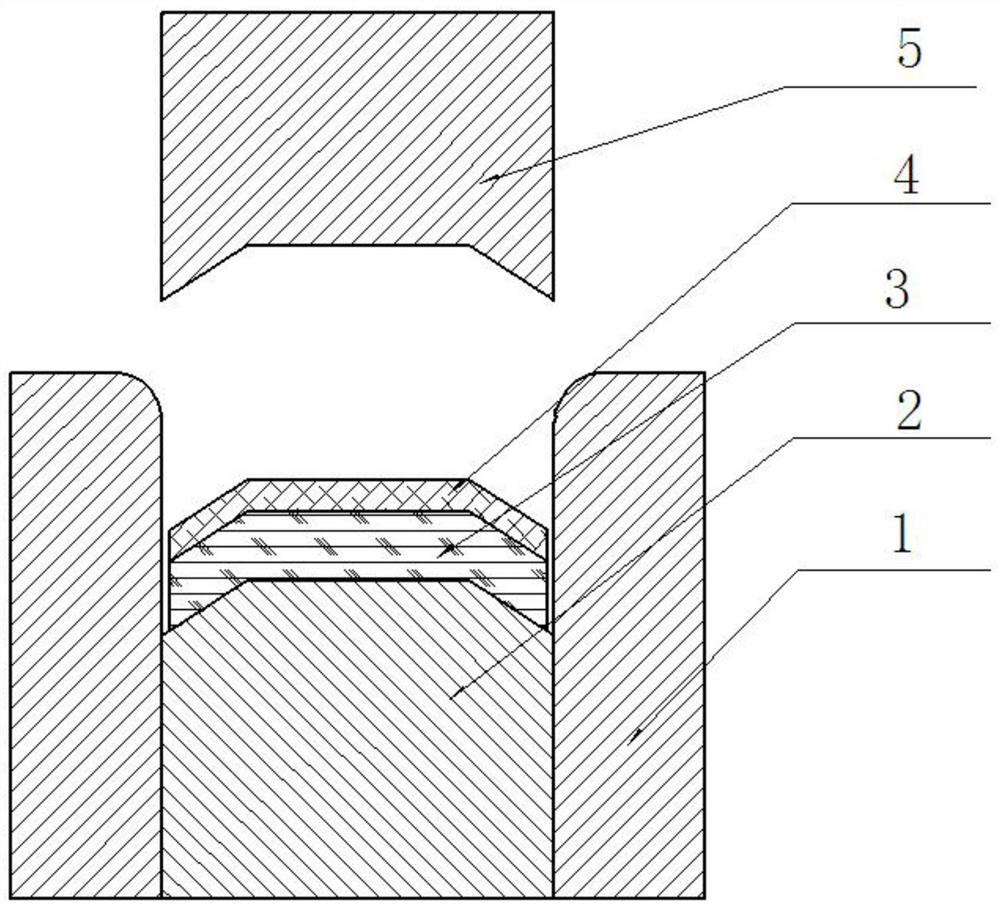

[0033] Step 1. Pre-fill 500g of Mo-W powder into the cavity composed of the cylinder body 1 and the lower mold 2 of the butterfly graphite mold, and use the butterfly-shaped thin PTFE scraper to arrange the surface of the Mo-W powder into a butterfly shape , and then cover the upper mold 5 and carry out pre-pressing under the pressure condition of 15MPa to form the molybdenum-tungsten powder layer 3; the mass content of tungsten in the Mo-W powder is 3%;

[0034] Step 2. Fill 150g of tungsten powder on the molybdenum-tungsten powder layer 3 formed in step 1, and use a butterfly-shaped thin PTFE scraper to arrange the surface of the tungsten powder into a butterfly shape to form a tungsten powder layer 4, and then cover it Die 5 is vacuum hot-pressed and sintered to obtain the crude butterfly-shaped molybdenum-tungsten bimetallic composite rotary target; -2 Pa, temperature 1500°C, pressure 55MPa, time 2h, heating rate 15°C...

Embodiment 2

[0038] This embodiment includes the following steps:

[0039] Step 1. Pre-fill 750g of Mo-W powder into the cavity composed of the cylinder body 1 and the lower mold 2 of the butterfly graphite mold, and use the butterfly-shaped thin PTFE scraper to arrange the surface of the Mo-W powder into a butterfly shape , then cover the upper mold 5 and carry out pre-pressing under the pressure condition of 20MPa to form the molybdenum-tungsten powder layer 3; the mass content of tungsten in the Mo-W powder is 5%;

[0040] Step 2. Fill 250g of tungsten powder on the molybdenum-tungsten powder layer 3 formed in step 1, and use a butterfly-shaped thin PTFE scraper to arrange the surface of the tungsten powder into a butterfly shape to form a tungsten powder layer 4, and then cover it Die 5 is vacuum hot-pressed sintered to obtain the crude butterfly-shaped molybdenum-tungsten bimetallic composite rotary target; the conditions for vacuum hot-pressed sintering are: vacuum degree 1.0×10 -2 ...

Embodiment 3

[0044] This embodiment includes the following steps:

[0045] Step 1. Pre-fill 1000g of Mo-W powder into the cavity composed of the cylinder body 1 and the lower mold 2 of the butterfly graphite mold, and use the butterfly-shaped thin PTFE scraper to arrange the surface of the Mo-W powder into a butterfly shape , and then cover the upper mold 5 to carry out pre-pressing under the pressure condition of 18MPa to form the molybdenum-tungsten powder layer 3; the mass content of tungsten in the Mo-W powder is 10%;

[0046] Step 2: Fill 400g of tungsten powder on the molybdenum-tungsten powder layer 3 formed in step 1, and use a butterfly-shaped thin PTFE scraper to arrange the surface of the tungsten powder into a butterfly shape to form a tungsten powder layer 4, and then cover it Die 5 is vacuum hot-pressed and sintered to obtain the crude butterfly-shaped molybdenum-tungsten bimetallic composite rotary target; -2 Pa, temperature 1700°C, pressure 50MPa, time 4h, heating rate 20°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com