Graphene in-situ modified epoxy SBS resin and preparation method thereof

An in-situ modification and graphene technology, applied in the field of SBS resin, can solve the problems of secondary agglomeration, yellowing, poor aging resistance, etc., and achieve good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

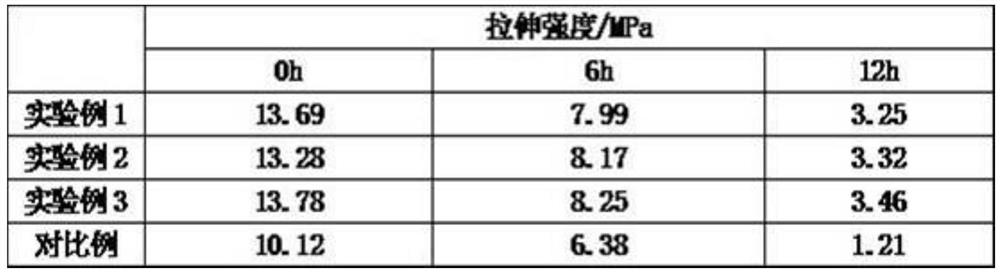

Examples

preparation example Construction

[0034] The preparation method of graphene in-situ modification epoxy SBS resin, this preparation method comprises:

[0035] The first step, the preparation of amino-functionalized graphene:

[0036] Ultrasonic dispersion of graphene oxide powder in a certain volume of benign solvent;

[0037] Slowly add diamine compounds with a mass ratio of 1:0.1-10 to the graphene oxide dispersion, and reflux at a temperature of 40-150°C for a reaction time of 2-48 hours to obtain a black dispersion;

[0038] After fully washing the obtained black dispersion with absolute ethanol, vacuum-dry and pulverize to obtain amino-functionalized graphene powder; the second step, the preparation of graphene in-situ modified epoxy SBS resin:

[0039] Dissolve epoxy SBS resin in a benign solvent,

[0040] Add the amino-functionalized graphene into the solution, disperse evenly by ultrasonic, then reflux reaction at a temperature of 40-120°C, the reaction time is 2-48h, and a black liquid with a certain...

Embodiment 1

[0059] The first step, preparation of amino-functionalized graphene:

[0060] Weigh 0.5g graphene oxide and ultrasonically disperse it in 1000mL water, the concentration of graphene oxide is 0.5mg / mL;

[0061] Weigh 0.25g of ethylenediamine, slowly add it to the graphene oxide dispersion, and react at 80°C for 24h to obtain a black dispersion;

[0062] After fully washing the obtained black dispersion with absolute ethanol, vacuum drying and pulverization obtains amino-functionalized graphene powder;

[0063] The second step, graphene in situ modified epoxy SBS resin:

[0064] Weigh 0.2g of epoxy SBS resin and dissolve it in 400ml of dichloromethane, the concentration of epoxy SBS resin is 0.5mg / mL; weigh 0.006g of amino functionalized graphene, add it to the dichloromethane of epoxy SBS resin In the methane solution, ultrasonically disperse evenly, and reflux at 70°C for 24 hours to obtain a black liquid with a certain viscosity;

[0065] The obtained black liquid was sett...

Embodiment 2

[0067] The first step, preparation of amino-functionalized graphene:

[0068] Weigh 0.2g graphene oxide and ultrasonically disperse it in 200mL N,N-dimethylformamide, the concentration of graphene oxide is 1mg / mL;

[0069] Weigh 0.2 g of 1,6-hexamethylenediamine, slowly add it to the graphene oxide dispersion, and react at 130°C for 8 hours to obtain a black dispersion;

[0070] After fully washing the obtained black dispersion with absolute ethanol, vacuum drying and pulverization obtains amino-functionalized graphene powder;

[0071] The second step, graphene in situ modified epoxy SBS resin:

[0072] Weigh 0.2g of epoxy SBS resin and dissolve it in 250ml of cyclohexane, the concentration of epoxy SBS resin is 0.8mg / mL;

[0073] Weigh 0.002g of amino-functionalized graphene, add it to the cyclohexane solution of epoxy SBS resin, ultrasonically disperse it evenly, and reflux at 100°C for 8 hours to obtain a black liquid with a certain viscosity;

[0074] The obtained black...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com