Nuclear control rod coil chamber and anti-corrosion method thereof, surface coating preparation method, and application of aluminum powder coating thereto

A technology for anti-corrosion coating and nuclear control, applied in the direction of anti-corrosion coatings, coatings, conductive coatings, etc., can solve problems such as complex operation, affecting coating anti-corrosion effect, large porosity, etc., achieve simple preparation method, guarantee anti-corrosion effect, The effect of dense coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

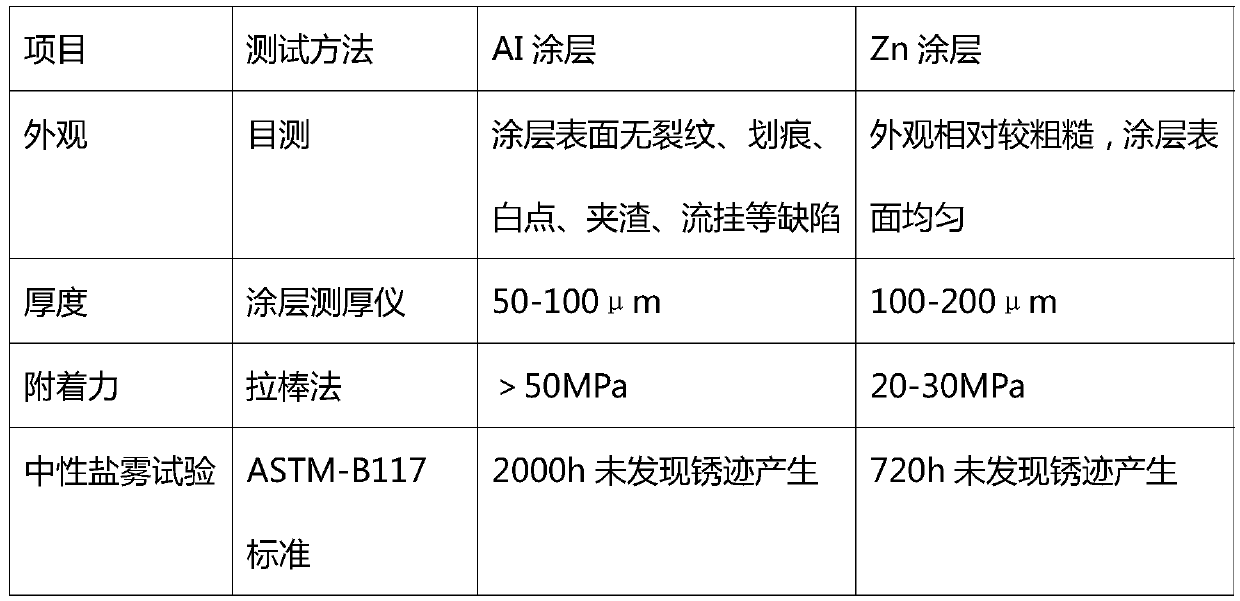

[0032] In this embodiment, the phosphate AI powder coating is sprayed on the surface of the nuclear control rod coil chamber, and the phosphate AI coating is prepared on the surface. The surface of the nuclear control rod coil chamber includes all surfaces of the nuclear control rod coil chamber, and all surfaces include but not only Limited to the outer surface, inner surface and small hole surface on the inner surface, the composition of phosphate AI powder coating includes phosphoric acid compound salt, aluminum powder, chromic anhydride and surfactant.

[0033] A method for preparing a phosphate AI coating on the surface of a nuclear control rod coil chamber, comprising the following steps:

[0034] Step a: Clean the surface of the coil chamber to be coated with a metal-specific cleaning agent to remove surface oil and foreign matter, and dry the surface of the coil chamber with clean compressed air;

[0035] Step b: Perform sandblasting pretreatment on the sprayed surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com