Preparation method for production of polyaluminium chloride water purification agent through aluminum ash

A technology of water purifying agent and aluminum ash, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., and can solve problems such as high production cost, small amount of ammonia escape, and poor water purification effect of water purifying agent , to achieve the effect of increasing adsorption performance, improving adsorption activity, and increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

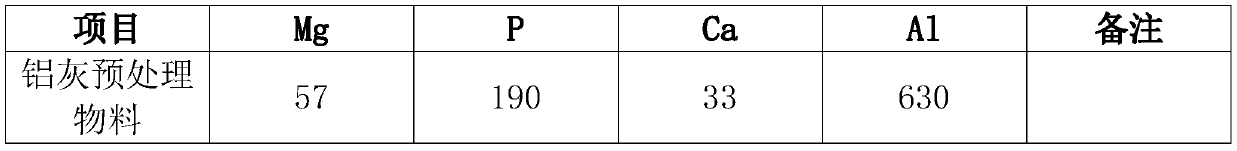

Embodiment 1

[0038] Aluminum ash pretreatment:

[0039] The aluminum ash is a mixture of infusible inclusions, oxides, additives, etc., floating on the surface of the aluminum melt during the production process of smelting aluminum and aluminum alloy.

[0040] (a) The aluminum ash and water are mixed and dissolved at a mass ratio of 1:2 under normal temperature conditions, and the solution is continuously stirred during the dissolution process at a stirring speed of 150-200 rpm;

[0041] (b) Lime (Ca(OH) is added during the dissolution process 2 Gradually adjust the solution to alkaline, increase the stirring intensity when the PH value reaches between 11-12.5, adjust the stirring speed to 400-500 rpm, add hydrogen peroxide to the solution for strong oxidation, so that the ammonia in the solution is Maximum decomposition and volatilization; at the same time, the reaction solution contains NH under alkaline conditions 4 OH, through H 2 O 2 Strong oxidation and NH 4 The OH dissolves, so that the di...

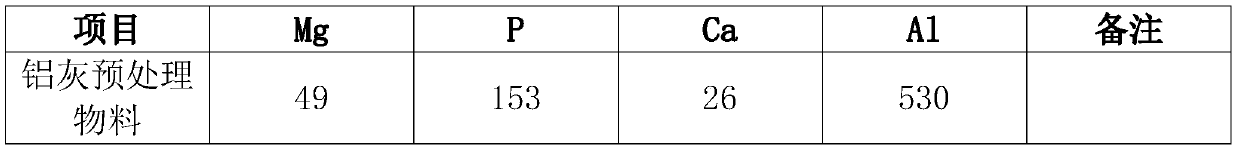

Embodiment 2

[0060] Aluminum ash pretreatment:

[0061] The aluminum ash is a mixture of infusible inclusions, oxides, additives, etc., floating on the surface of the aluminum melt during the production process of smelting aluminum and aluminum alloy.

[0062] (a) Mix and dissolve aluminum ash and water at a mass ratio of 1:3 under normal temperature conditions, and constantly stir the solution during the dissolution process at a stirring speed of 150-300 rpm;

[0063] (b) Lime (Ca(OH) is added during the dissolution process 2 Gradually adjust the solution to alkaline, increase the stirring intensity when the pH value reaches between 11-12.5, adjust the stirring speed to 400-800 rpm, add hydrogen peroxide to the solution for strong oxidation, so that the ammonia in the solution is Maximum decomposition and volatilization; at the same time, the reaction solution contains NH under alkaline conditions 4 OH, through H 2 O 2 Strong oxidation and NH 4 The OH dissolves, so that the dirt in the organic m...

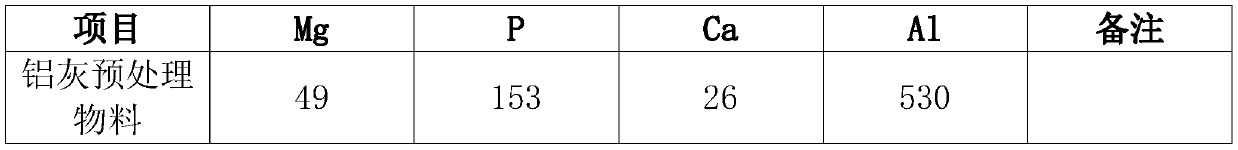

Embodiment 3

[0079] Aluminum ash pretreatment:

[0080] The aluminum ash is a mixture of infusible inclusions, oxides, additives, etc., floating on the surface of the aluminum melt during the production process of smelting aluminum and aluminum alloy. (Increase indicators)

[0081] (a) Mix and dissolve aluminum ash and water at a mass ratio of 1:3 under normal temperature conditions, and constantly stir the solution during the dissolution process at a stirring speed of 150-300 rpm;

[0082] (b) Lime (Ca(OH) is added during the dissolution process 2 Gradually adjust the solution to alkaline, increase the stirring intensity when the pH value reaches between 11-12.5, adjust the stirring speed to 400-800 rpm, add hydrogen peroxide to the solution for strong oxidation, so that the ammonia in the solution is Maximum decomposition and volatilization; at the same time, the reaction solution contains NH under alkaline conditions 4 OH, through H 2 O 2 Strong oxidation and NH 4 The OH dissolves, so that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com