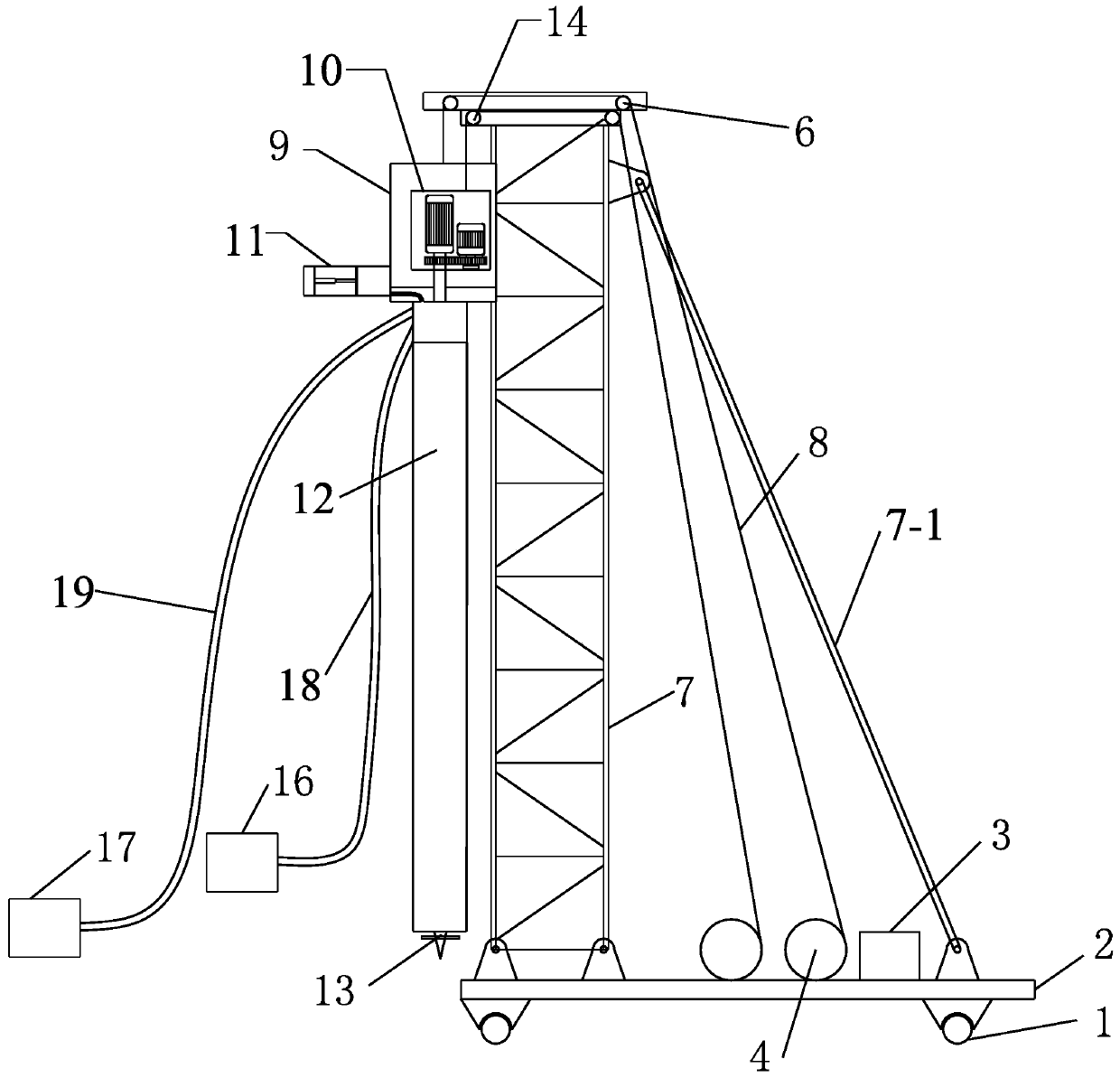

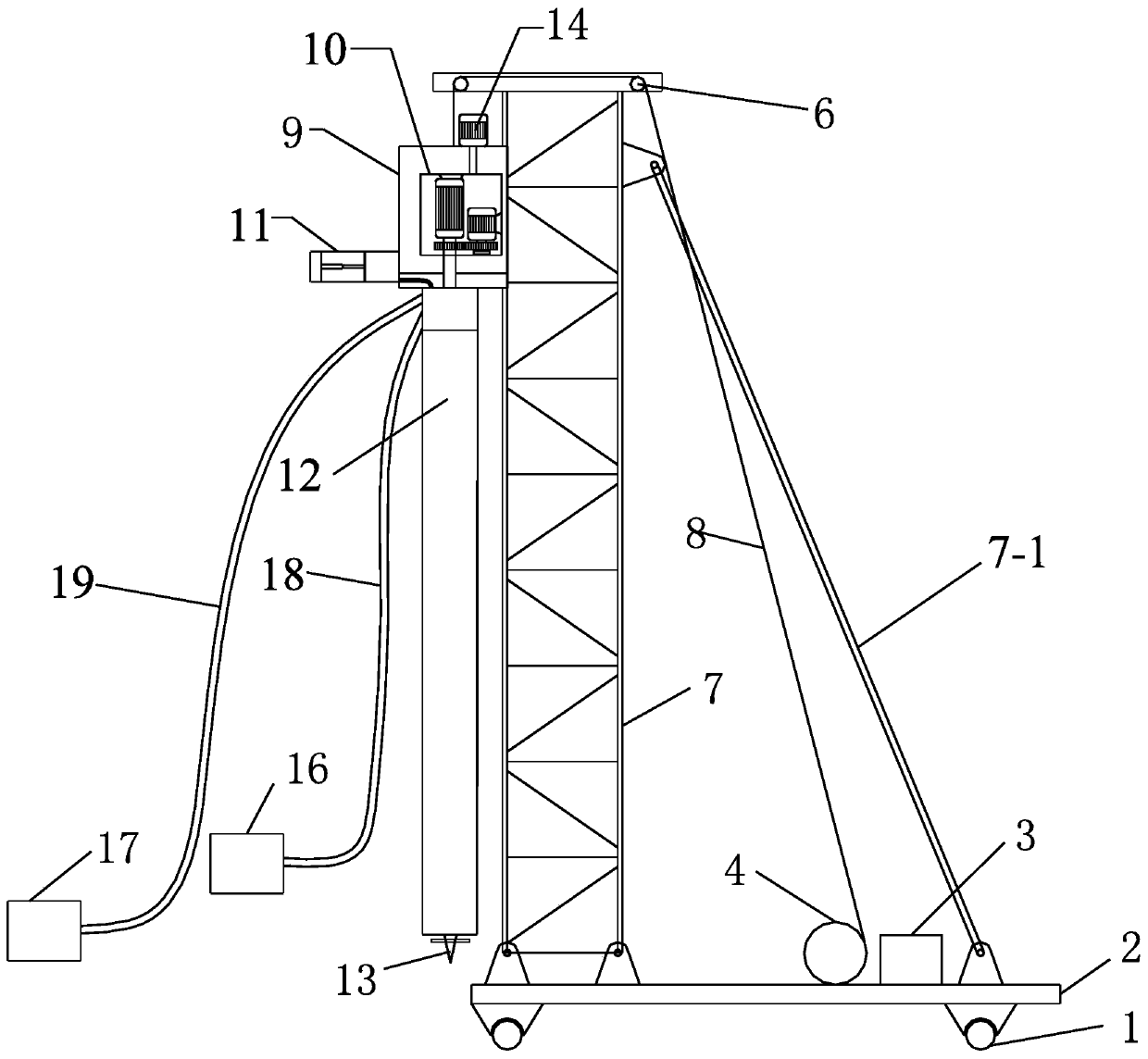

Multi-purpose pile-forming equipment capable of achieving forming of various piles

A piling and equipment technology, which is applied in drilling equipment, drilling equipment and methods, sheet pile walls, etc., can solve the problems of difficult to guarantee pile quality, high mechanical energy consumption, and high piling cost, so as to save the cost of prefabrication , low cost, high horizontal bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

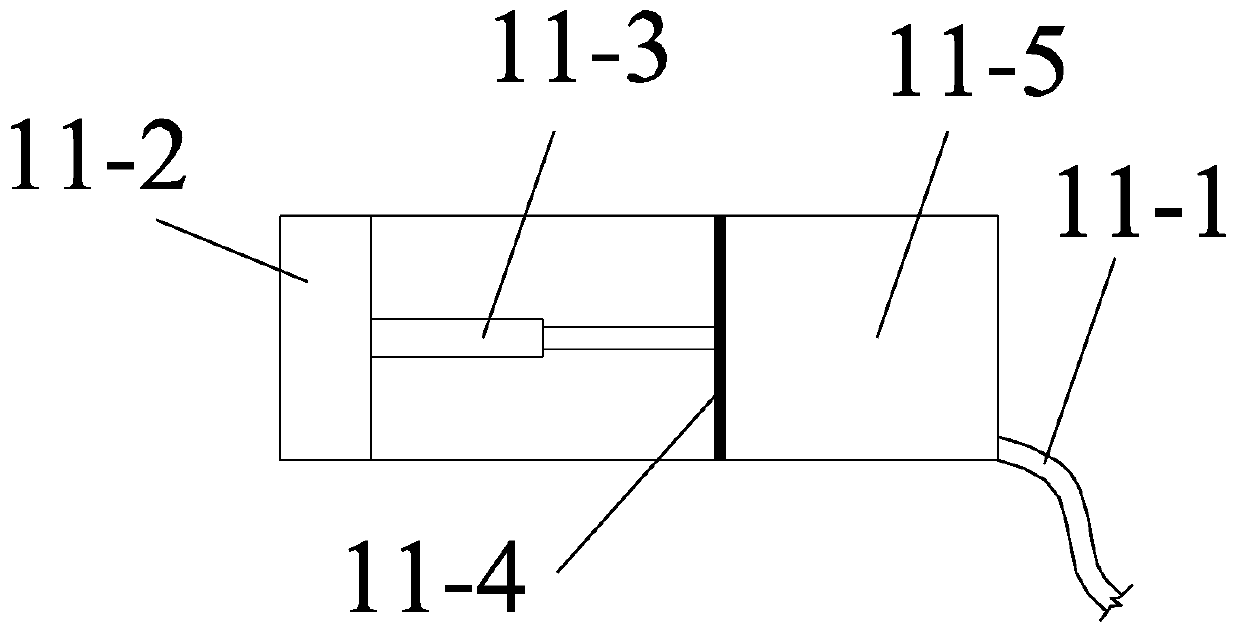

example 1

[0061] Example 1. The multi-purpose pile-forming equipment of the present invention is used to construct new-type pipe piles with intermediate high pressure cement soil and peripheral concrete. The specific construction process is as follows Figure 26 Shown: First, the central gear 13-3 is controlled to rotate a certain angle in the reverse direction through the blade expansion control motor 10-2, and the stirring blade 13-2 is driven to rotate a certain angle in the positive direction around the rotation positioning shaft 13-6, thereby reducing the blade rotation diameter to T1 , T1 is smaller than the inner diameter of the middle sleeve 12-2; the drill bit rotating motor 10-1 drives the cone tip and the mixing blade 13-2 fixed on the cone tip to rotate, and controls the entire drill tool to drill down into the soil. The rotating diameter of the mixing blade 13-2 is smaller than the inner diameter of the middle sleeve 12-2. During the downward drilling of the drilling tool, the...

example 2

[0062] Example 2: The multi-purpose pile forming equipment of the present invention is used to construct the external cement-soil pile and the internally cast-in-situ concrete core pile of the cement-soil mixing pile. The specific construction process is as follows Figure 27 Shown: First, the central gear 13-3 is controlled to rotate a certain angle in the forward direction through the blade expansion control motor 10-2, and the stirring blade 13-2 is driven to rotate a certain angle in the reverse direction around the rotation positioning shaft 13-6, thereby expanding the blade rotation diameter to T3 , T3 is greater than the outer diameter of the outer sleeve 12-3; the drill bit rotating motor 10-1 drives the cone tip and the mixing blade 13-2 fixed on the cone tip to rotate, and controls the entire drill tool to drill down into the soil layer. In the process of continuously sinking into the soil layer, open the second injection port 15 on the outer sleeve 12-3, inject the cem...

example 3

[0063] Example 3: The multi-purpose pile forming equipment of the present invention is used to construct cement-soil mixing piles. The construction process is the same as the previous construction process in Example 2. There is no need to reduce the blades to T1 before the mixing head is raised, and there is no need to move the drill bit. It is separately lifted into the middle sleeve 12-2, and the cement-soil mixing pile can be completed by spraying and mixing the cement slurry during the whole process. The whole piling process is like Figure 28 Shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com