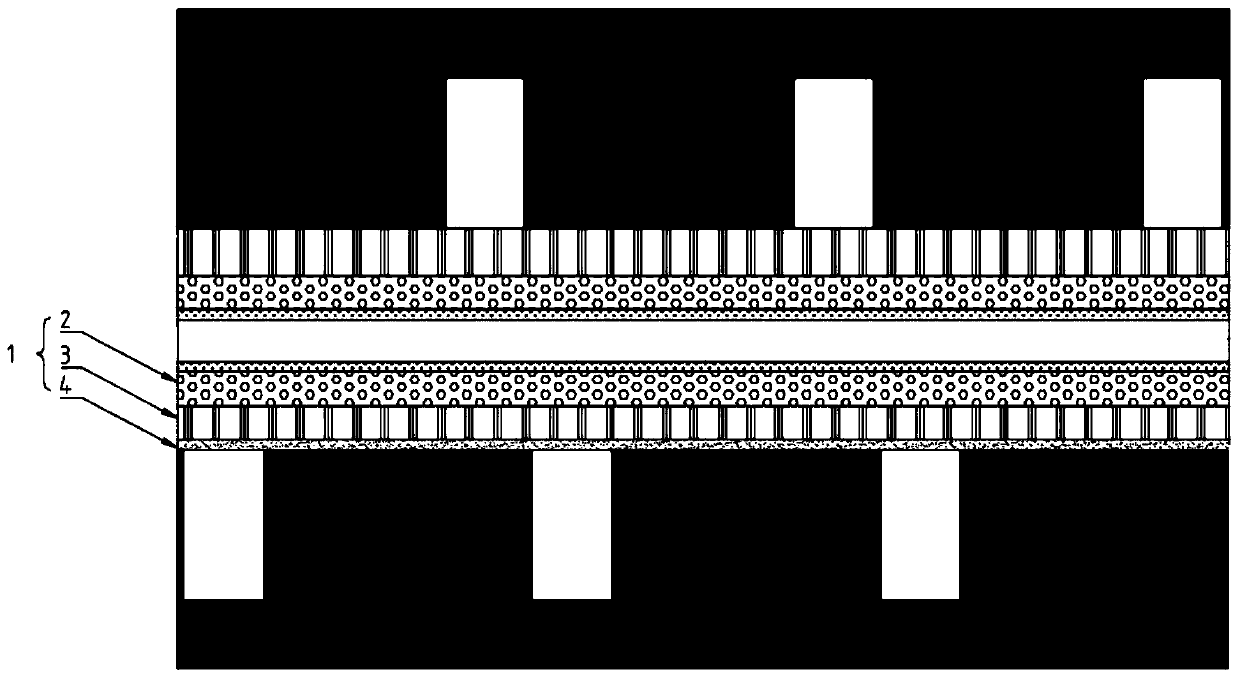

Anode gas diffusion layer for prolonging service life of metal bipolar plate and preparation method thereof

A technology of metal bipolar plate and gas diffusion layer, which is applied in the direction of electrical components, battery electrodes, structural parts, etc., can solve the problems of reducing battery durability, changing catalyst activity, and reducing membrane proton conductivity, so as to prolong service life, The effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing an anode gas diffusion layer for prolonging the service life of a metal bipolar plate, the method comprising the following steps:

[0034] Step 1. Add the dispersant to deionized water or distilled water, and form a uniform dispersant aqueous solution with a dispersant concentration of 0.1wt% to 2wt% through one or two dispersion methods;

[0035] Step 2, adding the conductive carbon material to the dispersant aqueous solution prepared in step 1, and forming a uniform conductive carbon material suspension through one or two dispersion methods;

[0036] Step 3, adding the water-repellent emulsion into the conductive carbon material suspension prepared in Step 2, and forming a microporous layer slurry containing a water-repellent concentration of 1 wt% to 60 wt% through one or two dispersion methods;

[0037] Step 4. The microporous layer slurry prepared in Step 3 is applied to one side of the hydrophobically treated support layer by one or more tha...

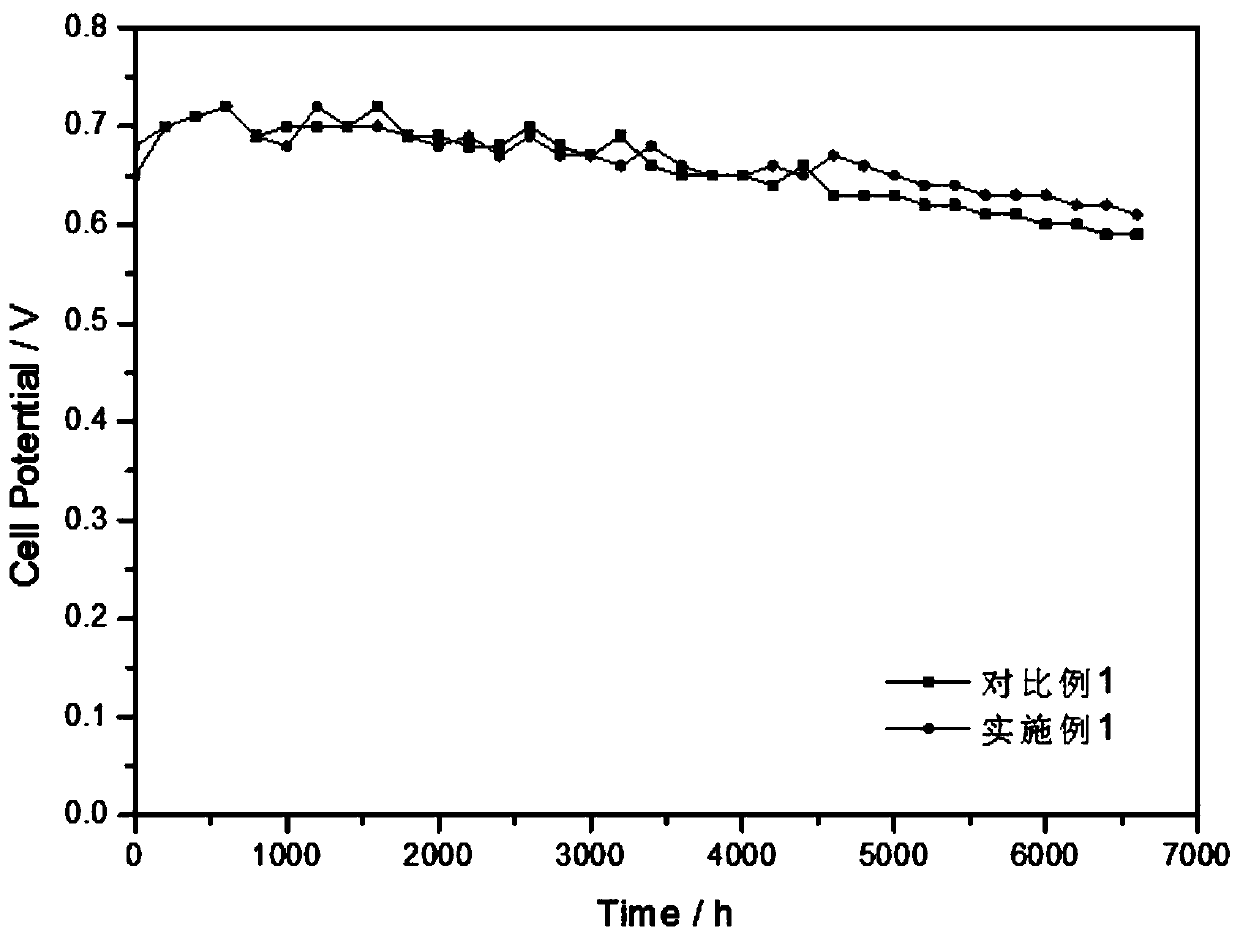

Embodiment 1

[0043]Add sodium lauryl sulfate and sodium isooctyl alcohol polyoxyethylene ether phosphate into distilled water, and mechanically stir for 2 hours to form a uniform dispersant solution with a concentration of 0.5 wt%; add activated carbon and carbon nanotubes In the above-mentioned dispersant aqueous solution, mechanically stir for 20 minutes to form a uniform conductive carbon material suspension; add polytetrafluoroethylene emulsion to the above-mentioned conductive carbon material suspension, and ultrasonically disperse for 1 minute to form a microparticle with a water-repellent concentration of 20 wt%. Porous layer slurry: Apply the above microporous layer slurry to the side of the hydrophobically treated support layer by scraping and spraying, first place it in a 105°C oven, heat it and weigh it, and then repeat this step until it is conductive The loading amount of the carbon material reaches 1.5mg / cm2 and the loading amount of the hydrophobic agent reaches 40% of the to...

Embodiment 2

[0046] Add polyvinylpyrrolidone to deionized water and stir mechanically for 1 hour to form a uniform dispersant solution with a concentration of 0.1 wt %; add conductive carbon black to the above aqueous dispersant solution and stir mechanically for 10 minutes to form a uniform conductive carbon Material suspension: adding polychlorotrifluoroethylene and polyvinylidene fluoride emulsion to the conductive carbon material suspension, mechanically stirring for 1 minute, and ultrasonically dispersing for 30 minutes to form a microporous layer slurry with a water repellent concentration of 1 wt%. Put the above-mentioned microporous layer slurry to the side of the hydrophobically treated support layer by means of suction filtration, first place it in a 100°C oven, heat and weigh it, and then repeat this step until the loading capacity of the conductive carbon material reaches 0.1 The loading amount of mg / cm2 and water-repellent agent reaches 60% of the total mass of water-repellent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com