A carbon dioxide mineralization power generation method using organic matter as a catalyst

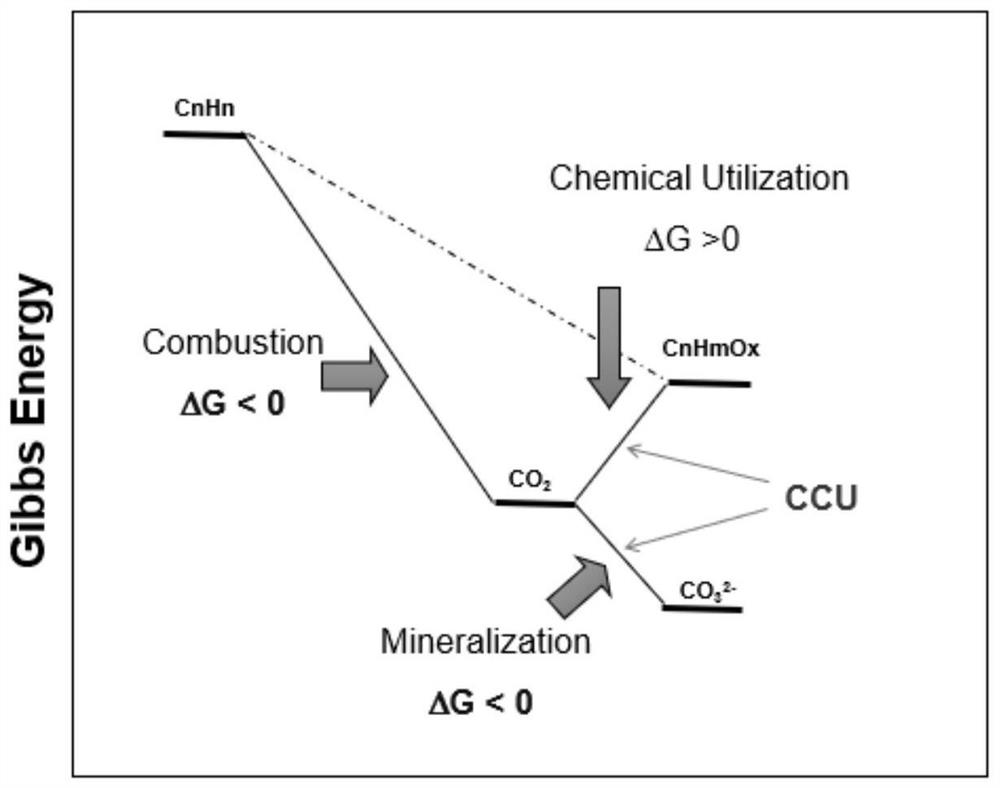

A carbon dioxide and organic matter technology, applied in the field of carbon dioxide mineralization and power generation, can solve the problems of low power generation efficiency and high cost, and achieve the effect of reducing production costs and reducing CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

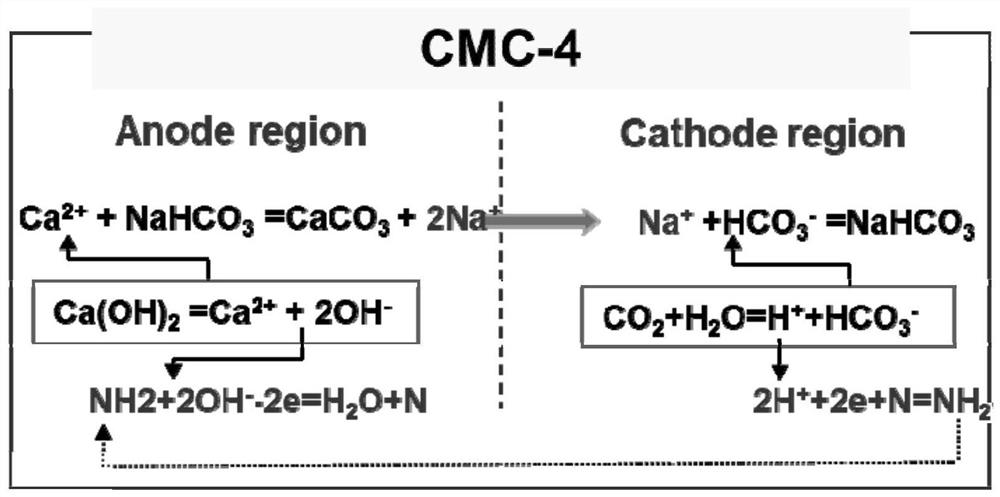

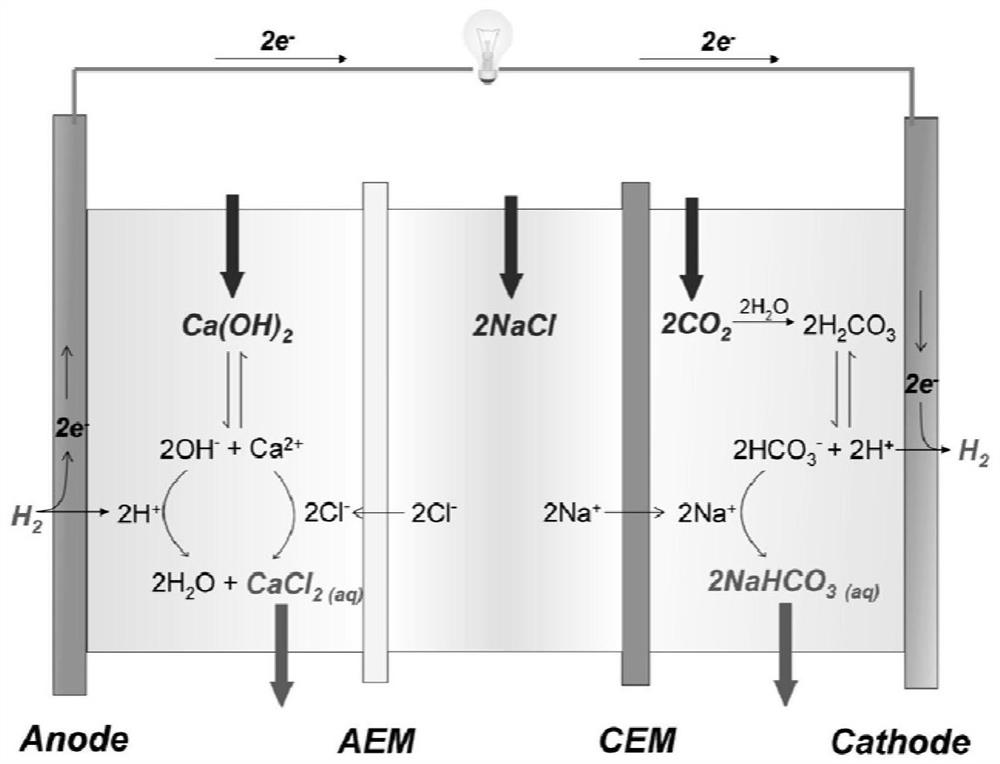

[0041] The technical process of this embodiment is as attached Figure 4 and 5 shown. The effective area in the electrolytic cell is 4cm 2 electrolyzer. The electrolytic cell is divided into two areas, the anode area and the cathode area, by a cation exchange membrane that only allows cations to pass through but prevents anions from passing through.

[0042] Add 50ml of NaOH, 0.4mol / LNH2, 1mol / L KCl solution with a concentration of 1.4mol / L in the anode area as the anolyte, and add 50ml of NaHCO with a concentration of 1.mol / L 3 , 0.4mol / L N and 1mol / L KCl solution to the cathode area as the electrolyte and at the same time as the reaction raw material, connected to the load.

[0043] The program of load output electricity is to increase the current by 0.001A per second until the voltage will be 0 and stop. Initially, the load output function is not turned on, and the open circuit voltage displayed by the load will increase from 0V until the open circuit voltage increases...

Embodiment 2

[0045] The technical process of this embodiment is as attached figure 1 and 2 shown. The electrolytic cell is divided into two areas, the anode area and the cathode area, by a cation exchange membrane that only allows cations to pass through but prevents anions from passing through. Add 100ml of NaOH, 0.4mol / LNH2, 1mol / L KCl solution with a concentration of 1.4mol / L in the anode area as the anolyte, and add 100ml of NaHCO with a concentration of 1.mol / L 3 , 0.4mol / L N and 1mol / L KCl solution to the cathode area as the electrolyte and at the same time as the reaction raw material, connected to the load. At the same time, two other identical anode and cathode electrolysis preparations were prepared for use.

[0046] Load fixed current 100ml, output power density is 83.6W / m 2 , After about 10 hours of stable power generation, replace the electrolyte with a spare solution to continue power generation. At this time, the replaced anolyte is 1mol / L NaOH, 0.2mol / L NH2, 0.2mol / LN,...

Embodiment 3

[0051] The technical process of this embodiment is as attached figure 1 and 2 shown. The effective area in the electrolytic cell is 1m 2 The semi-industrial-grade electrolyzer consists of 13 identical electrolyzers, the solutions are connected in series, and the current is connected in parallel. The electrolytic cell is divided into two areas, the anode area and the cathode area, by a cation exchange membrane that only allows cations to pass through but prevents anions from passing through.

[0052] Add 20L of NaOH, 0.4mol / LNH2, 1mol / LKCl solution with a concentration of 1.4mol / L in the anode area as the anolyte, and add 20L of NaHCO with a concentration of 1.mol / L 3 , 0.4mol / L N and 1mol / L KCl solution to the cathode area as the electrolyte and at the same time as the reaction raw material, connected to the load.

[0053] The program of load output electricity is to increase the current by 0.1A per second until the voltage will be 0 and stop. Initially, the load output f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com