Bacillus subtilis controlled release agent and preparing method thereof

A technology of Bacillus subtilis and controlled release agent, which is applied in the directions of botanical equipment and methods, biochemical equipment and methods, fungicides, etc. Wettable powder dust flying and other problems, to achieve good microcapsule structure, good controlled release effect, reduce the effect of the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

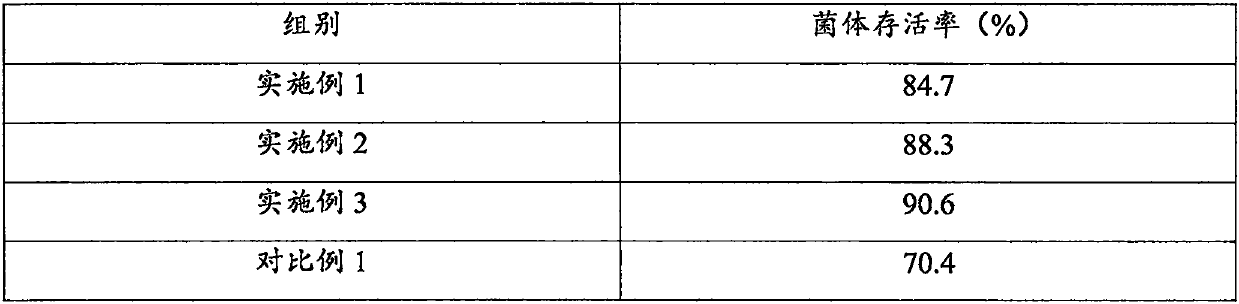

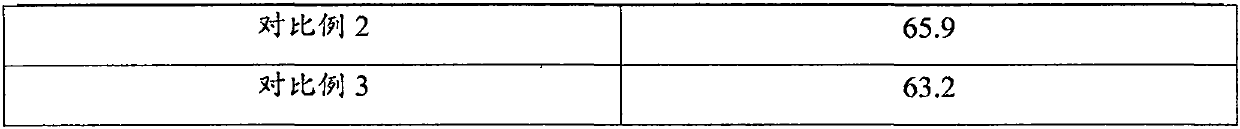

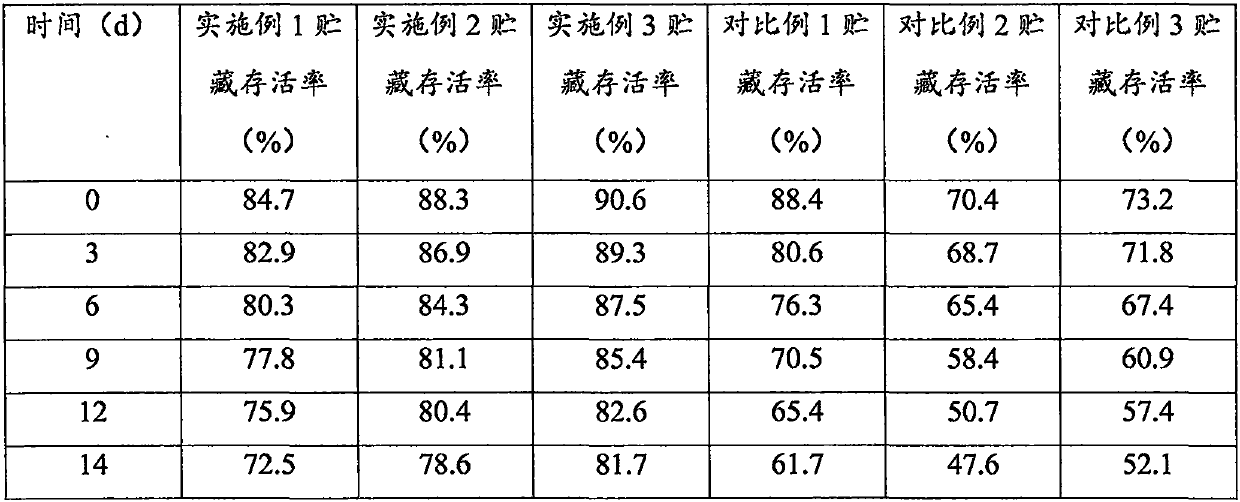

Examples

Embodiment 1

[0027] (1) Strain activation:

[0028] Take out the Bacillus subtilis HU2012 stored in the refrigerator at 4°C, and place it at room temperature for 10 minutes. Then use an inoculation loop to inoculate the pre-made MHA medium by streaking on a plate, and carry out activation culture at 37±1°C for 24 hours, and set aside.

[0029] (2) Preparation of seed medium:

[0030] The components of the seed medium are: 200g of potato decoction, 20g of glucose, 1000ml of water is added, and the pH value is adjusted to 7.0.

[0031] (3) Preparation of seed solution: Inoculate activated Bacillus subtilis HU2012 into the above seed medium, ferment at 40° C., and ferment for 12 hours.

[0032] (4) Preparation of fermented liquid: inoculate the above seed liquid into the fermentation medium, the inoculum amount is 1% of the volume of the fermentation medium, the pressure of the fermenter is 0.25MPa, the fermentation temperature is 25°C, and the fermentation time is 48h.

[0033] (5) 500kg ...

Embodiment 2

[0037] (1) Strain activation:

[0038] Take out the Bacillus subtilis HU2012 stored in the refrigerator at 4°C, and place it at room temperature for 10 minutes. Then use an inoculation loop to inoculate the pre-made MHA medium by streaking on a plate, and carry out activation culture at 37±1°C for 24 hours, and set aside.

[0039] (2) Preparation of seed medium:

[0040] The components of the seed medium are: 300g of potato decoction, 10g of glucose, 1000ml of water is added, and the pH value is adjusted to 7.0.

[0041] (3) Preparation of seed solution: Inoculate activated Bacillus subtilis HU2012 into the above seed medium, ferment at 35° C., and ferment for 36 hours.

[0042] (4) Preparation of fermentation liquid: inoculate the above seed liquid into the fermentation medium, the inoculum amount is 5% of the volume of the fermentation medium, the pressure of the fermenter is 0.05MPa, the fermentation temperature is 35°C, and the fermentation time is 24h.

[0043] (5) 100...

Embodiment 3

[0047] (1) Strain activation:

[0048] Take out the Bacillus subtilis HU2012 stored in the refrigerator at 4°C, and place it at room temperature for 10 minutes. Then use an inoculation loop to inoculate the pre-made MHA medium by streaking on a plate, and carry out activation culture at 37±1°C for 24 hours, and set aside.

[0049] (2) Preparation of seed medium:

[0050] The components of the seed medium are: 250g of potato decoction, 15g of glucose, 1000ml of water is added, and the pH value is adjusted to 7.0.

[0051] (3) Preparation of seed solution: Bacillus subtilis HU2012 was inoculated into the above seed medium, the fermentation temperature was 37° C., and the fermentation time was 24 hours.

[0052] (4) Preparation of fermented liquid: inoculate the above seed liquid into the fermentation medium, the inoculum amount is 3% of the volume of the fermentation medium, the pressure of the fermenter is 0.15MPa, the fermentation temperature is 30°C, and the fermentation ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com