Soft magnetic ferrite material and preparation method thereof

A technology of soft magnetic ferrite and main crystal phase, which is applied in the manufacture of inductors/transformers/magnets, the magnetism of inorganic materials, and electrical components. It can solve the problems of low magnetic flux density and impact, and achieve reduced loss performance, rich raw materials, and Effect of improving flow resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

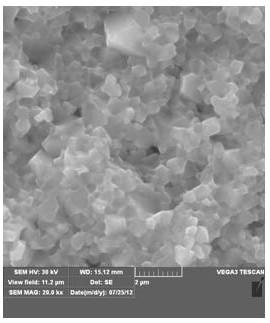

Image

Examples

Embodiment Construction

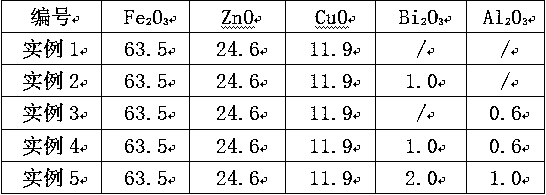

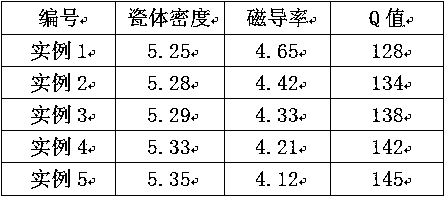

[0018] The present invention adopts the Fe of analytical purity 2 o 3 , ZnO, CuO as raw materials to prepare the main crystal phase, the purity of the analytically pure Bi 2 o 3 、Al 2 o 3 Doping, the specific implementation method is as follows: weigh the ingredients according to Table 1, put the mixture into the stirring ball mill tank, according to the mass ratio of material ball to water 1:2:0.8, ball mill for 2 to 6 hours, and the speed is 260 rpm minute. The particle size is controlled at D 50 = within 1.2μm, press-filter the ball-milled material, dry in an oven at 100°C, pass through a 40-mesh sieve after crushing, pre-fire in a box-type resistance furnace at 870°C / 4H, pass through a 40-mesh sieve after crushing Standby; add doping phase material Bi according to the ratio in Table 1 2 o 3 、Al 2 o 3 Carry out secondary ball milling, press filtration, drying, pass through an 80-mesh sieve after crushing, add PVA to granulate, and use a manual press at 20MPa to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com