Cyclodextrin star polymer, preparation method and application of cyclodextrin star polymer, and fracturing fluid

A star-shaped polymer and cyclodextrin technology, applied in the field of reservoir fracturing, can solve the problems of porosity and permeability reduction, affect the effect of fracturing reconstruction, destroy the structure of salt layer, etc., and achieve the effect of reducing dissolution and thickening Obvious, good shear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

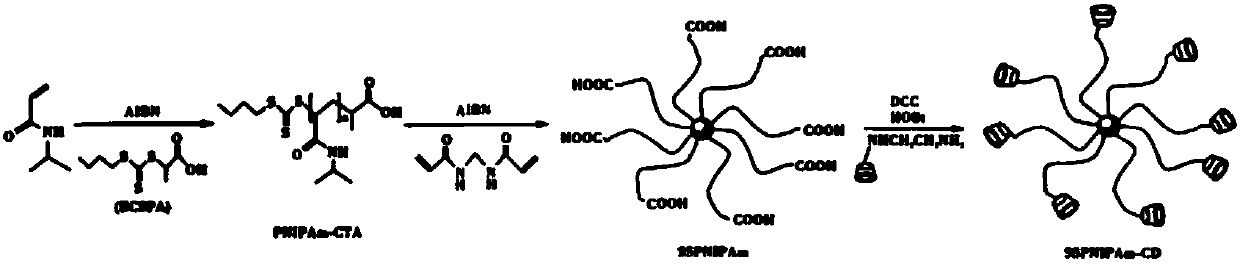

[0021] The preparation method of cyclodextrin star polymer provided by the invention comprises the following steps:

[0022] (1) performing the first reversible addition-chain scission transfer reaction of monofunctional acrylamide monomers and carboxyl-terminated dithioester compounds to obtain macromolecular chain transfer agents;

[0023] (2) performing a second reversible addition-chain scission transfer reaction on the macromolecular chain transfer agent and a difunctional acrylamide monomer to obtain a star polymer;

[0024] (3) Perform amidation reaction of the star polymer and aminocyclodextrin.

[0025] It is well known to those skilled in the art that the term "reversible addition-chain scission transfer reaction" means that in the free radical polymerization process, when a dithioester compound exists, the reversible reaction between the polymer growth chain and the dithioester compound occurs. Addition, reversible cleavage of adducts and chain transfer reactions, ...

Embodiment approach

[0035] The method of the amidation reaction is not particularly limited in the present invention. According to a preferred embodiment of the present invention, the amidation reaction is carried out by adding a catalyst and a dehydrating agent to the star-shaped polymer under ice-bath conditions and stirring for 15-35 minutes, and then the reaction system is The temperature was raised to 20-50° C. and the stirring reaction was continued for 20-36 hours, then aminocyclodextrin was added and the temperature was maintained at 20-50° C. and the stirring reaction was continued for 50-80 hours. After in-depth research, the inventors of the present invention found that the amidation reaction in this preferred manner can reduce side reactions to a very low level and increase the yield of the final product.

[0036] In the present invention, in order to control the reaction rate and avoid the occurrence of side reactions as much as possible, the first reversible addition-chain scission ...

Embodiment 1

[0046] This example is used to illustrate the cyclodextrin star polymer and its preparation method provided by the present invention.

[0047] (1) Synthesis of macromolecular chain transfer agent PNIPAm-CTA

[0048] NIPAm (N-isopropylacrylamide, 6g, 0.053mol), BCSPA (S-1-butanyl-S'-(α-methyl-α'-acetic acid) trithiocarbonate, 0.158g, 0.00053mol) and AIBN (azobisisobutyronitrile, 10.88mg) were successively dissolved in 18mL of dioxane, and then the resulting reaction mixture solution was filled with nitrogen and deoxygenated under magnetic stirring for 30min, during which ultrasonic waves were used 3 times, each time Last for 1min. Then the reaction mixture solution was placed in an oil bath at 65° C. for polymerization for 17 h. After the reaction was completed, the product was precipitated with ether after the system was cooled to room temperature, and the product was dissolved in a tetrahydrofuran (THF)-ether mixture (volume ratio 1:1) and purified by precipitation once, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com