Selective radiation refrigeration coating and composite material and application method thereof

A radiation cooling and selective technology, applied in the field of material science, can solve the problems of low mechanical strength, little practical value, poor weather resistance, etc., and achieve the effect of good weather resistance, great practical value, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

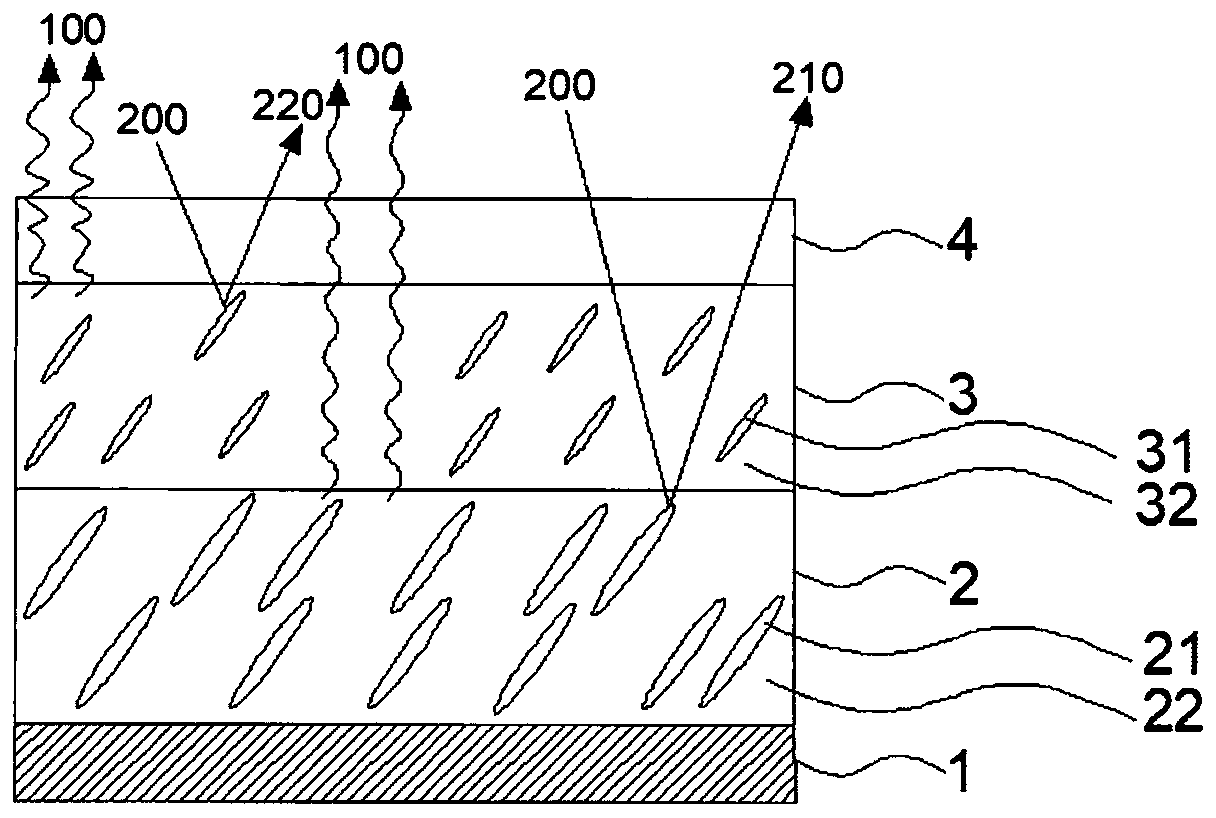

[0114] The coating preparation method of the selective radiation refrigeration coating of the present invention may include brush coating, roller coating and spray coating. The coating preparation process may include: preparing raw materials such as resin, granular fillers, additives and / or solvents, first pre-dispersing at high speed, then grinding and dispersing, then stirring evenly, then filtering and testing, and then packaging to prepare the layers of the coating. The primer resin layer, the first radiant cooling functional layer, the second radiative cooling functional layer, and the weather-resistant resin layer of the paint can be coated on the surface of the substrate in sequence by brushing, roller coating, and spraying, and one layer can be used. Apply the next coat after drying.

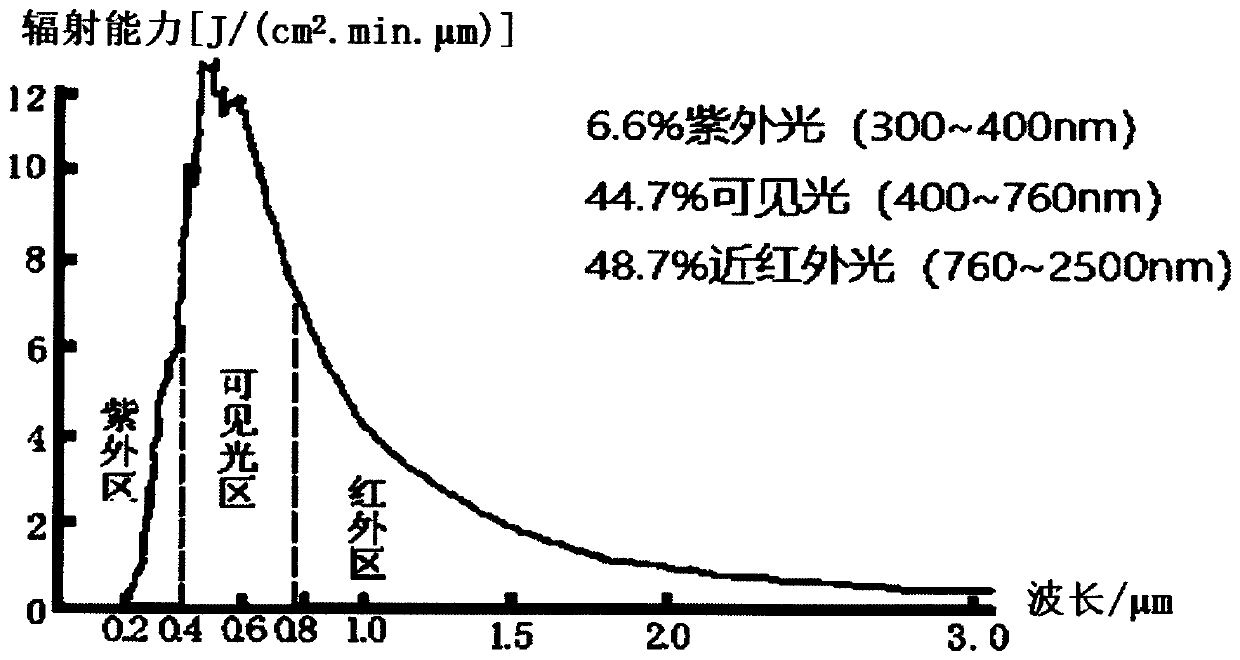

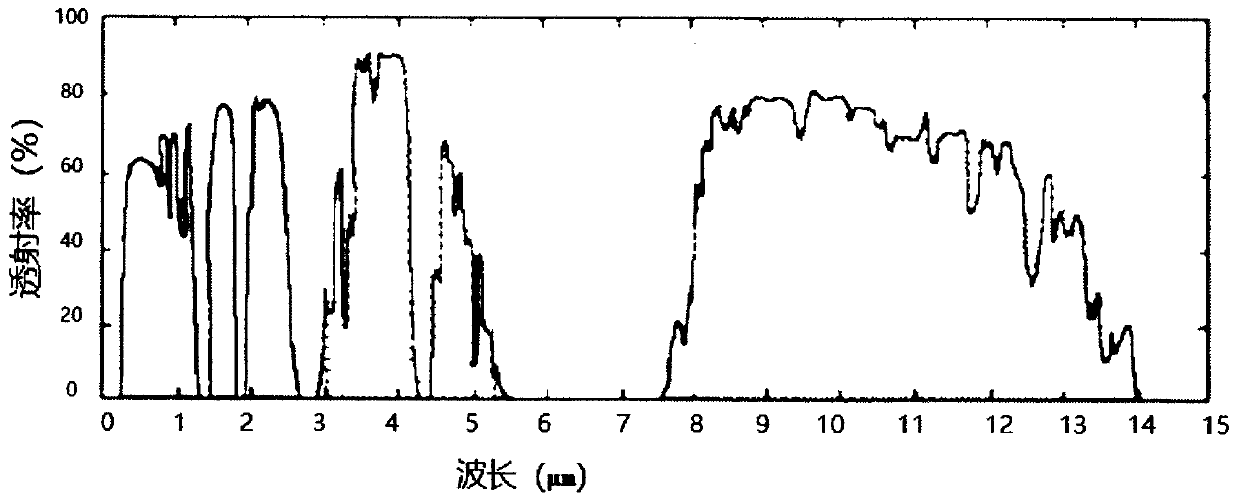

[0115] The selective radiation refrigeration coating of the present invention has a reflectivity of solar spectrum energy greater than or equal to 80%, an atmospheric window emissivity o...

example 1

[0177] Example 1: Showcase

[0178] In order to illustrate the cooling and cooling effect of the selective radiation cooling coating, the application of the selective radiation cooling coating to a building is taken as an example for illustration below.

[0179] The stainless steel exhibition house with internal length, width and height of 5m, 4m and 3m is coated with selective radiation cooling paint on the outside of the roof and four walls. The selective radiation cooling paint includes a primer with a thickness of 20 μm from bottom to top Resin layer 1 (the primer resin layer 1 includes acrylic resin), the first radiative cooling functional layer 2 (formulation X) with a thickness of 100 μm, the second radiative cooling functional layer 3 (formulation Y) with a thickness of 15 μm, and a thickness of For the 20 μm weather-resistant resin layer 4 (polyvinylidene fluoride resin), the reflectivity of the selective radiation refrigeration coating is 91% at 0.3 μm to 2.5 μm, a...

example 2

[0187] Example 2: Water Tank

[0188] In order to illustrate the cooling effect of the selective radiation cooling paint, the following uses the selective radiation cooling paint as an example for description.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com