Microbial agent for treating latrine pit and preparing method and application of microbial agent

A technology of microbial agent and dry toilet, which is applied in the field of microbial agent for dry toilet and its preparation, and achieves the effect of good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] 1. Preparation of Lactobacillus reuteri bacteria liquid

[0021] Pick a loop of Lactobacillus reuteri GIM 1.614 from the Lactobacillus slant medium and inoculate it into the liquid Lactobacillus seed medium, and culture it statically at 30-37°C for 12-48 hours until the strain is in the logarithmic During the growth period, the culture was stopped to obtain the first-class bacterial classification of Lactobacillus reuteri; 30-37°C, static airtight fermentation time 24-72 hours, to obtain Lactobacillus reuteri (Lactobacillus reuteri) GIM 1.614 bacterial liquid, said Lactobacillus reuteri slant medium contains 10.0g of peptone per liter, 10.0g of beef extract g, yeast extract 5.0g, diammonium hydrogen citrate [(NH 4 ) 2 HC 6 h 5 o 7 ] 2.0g, glucose (C 6 h 12 o 6 ·H 2 O) 20.0g, Tween 80 1.0mL, sodium acetate (CH 3 COONa·3H 2 O) 5.0g, dipotassium hydrogen phosphate (K 2 HPO 4 ·3H 2 O) 2.0g, magnesium sulfate (MgSO 4 ·7H 2 O) 0.58g, manganese sulfate (MnSO 4...

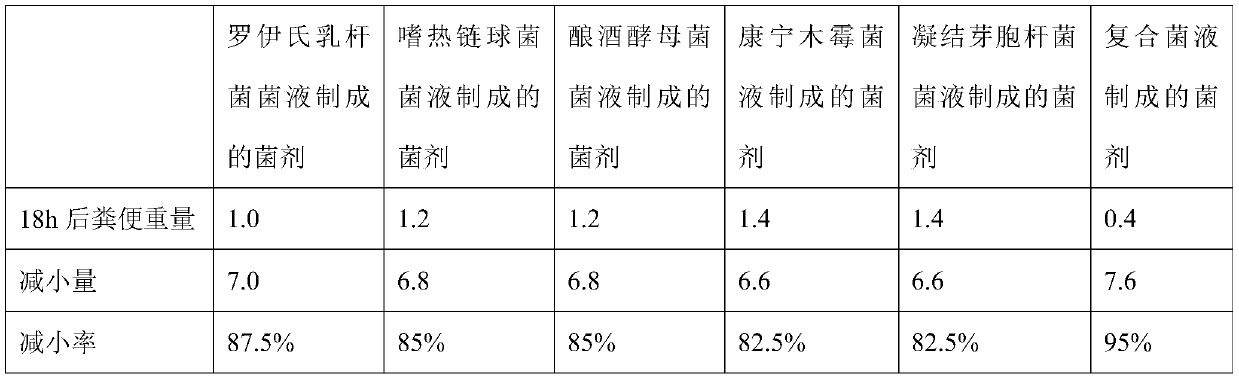

Embodiment 1

[0033] The above-mentioned Lactobacillus reuteri (Lactobacillus reuteri) GIM 1.614 bacterial liquid, Streptococcus thermophilus (Streptococcus thermophilus) CICC 201 bacterial liquid, Saccharomyces cerevisiae (Saccharomyces cerevisiae) ATCC 9763 Bacterial liquid, Trichoderma koningii (Trichoderma koningii) ACCC 30388 bacterial liquid and Bacillus coagulans (Bacillus coagulans) ATCC7050 bacterial liquid in bacterial content, then the adjusted Lactobacillus reuteri (Lactobacillus reuteri) GIM 1.614 bacterial liquid, Streptococcus thermophilus CICC 201 bacterial fluid, Saccharomyces cerevisiae ATCC 9763 bacterial fluid, Trichoderma koningii ACCC 30388 bacterial fluid and Bacillus coagulans ATCC 7050 bacterial fluid were mixed to form a composite bacteria liquid, so that the composite bacteria liquid contains Lactobacillus reuteri (Lactobacillus reuteri) GIM 1.6141.5 × 10 10 Individual / L, Streptococcus thermophilus CICC 201 1.5×10 12 Units / L, Saccharomyces cerevisiae ATCC 9763 2....

Embodiment 2

[0038] The above-mentioned Lactobacillus reuteri (Lactobacillus reuteri) GIM 1.614 bacterial liquid, Streptococcus thermophilus (Streptococcus thermophilus) CICC 201 bacterial liquid, Saccharomyces cerevisiae (Saccharomyces cerevisiae) ATCC 9763 Bacterial liquid, Trichoderma koningii (Trichoderma koningii) ACCC 30388 bacterial liquid and Bacillus coagulans (Bacillus coagulans) ATCC7050 bacterial liquid in bacterial content, then the adjusted Lactobacillus reuteri (Lactobacillus reuteri) GIM 1.614 bacterial liquid, Streptococcus thermophilus CICC 201 bacterial fluid, Saccharomyces cerevisiae ATCC 9763 bacterial fluid, Trichoderma koningii ACCC 30388 bacterial fluid and Bacillus coagulans ATCC 7050 bacterial fluid were mixed to form a composite bacteria liquid, so that the composite bacteria liquid contains Lactobacillus reuteri (Lactobacillus reuteri) GIM 1.6142.5 × 10 10 Individual / L, Streptococcus thermophilus CICC 201 3.5×10 12 Individuals / L, Saccharomyces cerevisiae ATCC 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com