cis gene chip and its making method

A technology of a gene chip and a production method, which is applied to the field of CIS gene chip and its production, can solve the problems of low sensitivity, large size of the test instrument, and reduce the test accuracy rate, so as to improve the accuracy rate, improve the signal sensitivity, and improve the mass production. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

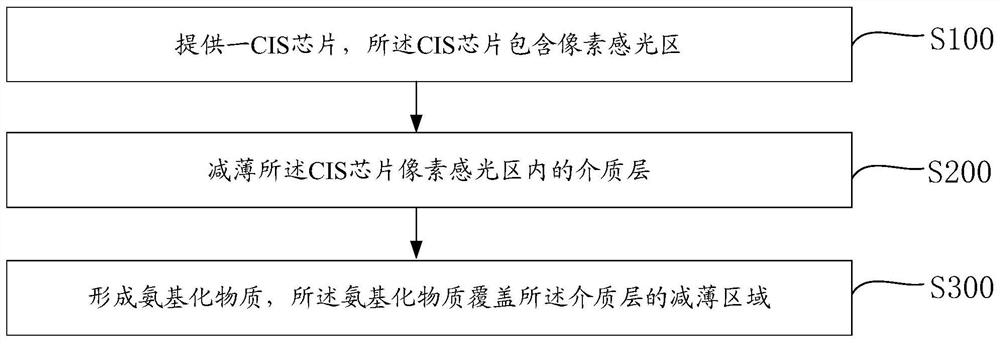

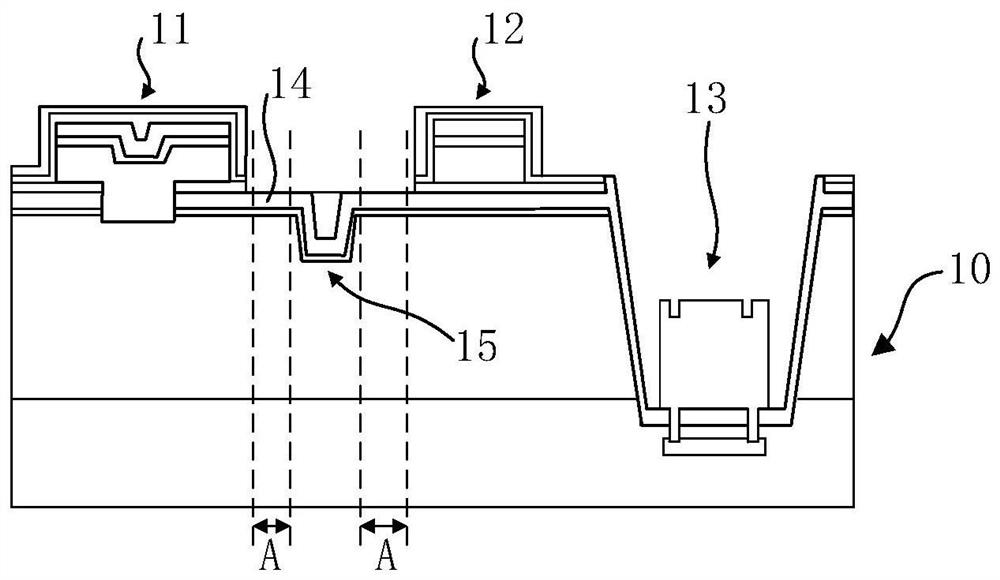

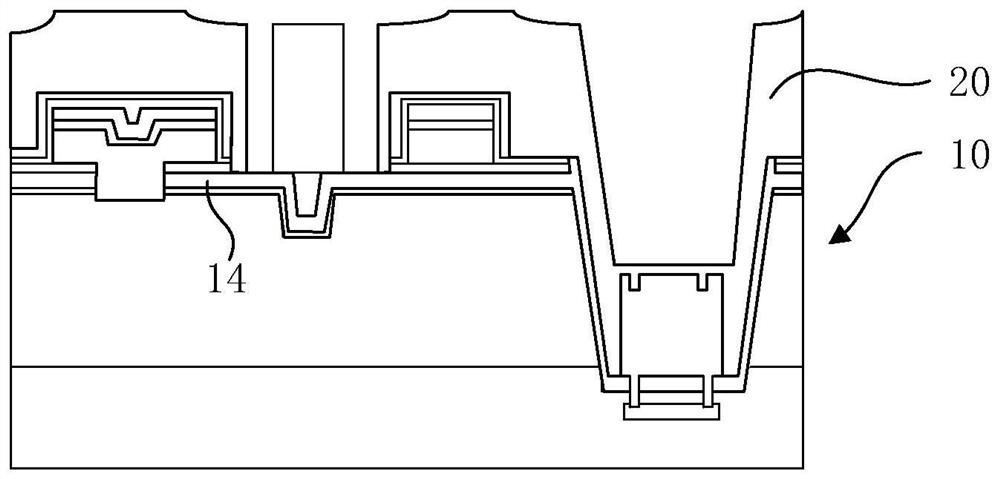

[0035] Based on the above problems, the present invention provides a method for manufacturing a CIS (CMOS Image Sensor, CMOS image sensor) gene chip, including: providing a CIS chip, the CIS chip including a pixel photosensitive area, and thinning the pixel photosensitive area of the CIS chip a dielectric layer within, and an amined species is formed that covers the thinned region of the dielectric layer.

[0036] Correspondingly, the present invention also provides a CIS gene chip, comprising: a CIS chip, the CIS chip includes a pixel photosensitive region, and the thickness of the dielectric layer in the pixel photosensitive region is smaller than the thickness of the dielectric layer in the remaining regions, and Aminated substances, the aminated substances are located on the relatively thin dielectric layer in the pixel photosensitive region.

[0037] In the CIS gene chip and the manufacturing method thereof provided by the present invention, the dielectric layer in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com