Method for preparing nanoparticles in situ by transmission electron microscope

A nanoparticle, transmission electron microscope technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor dispersion, large size of metal catalyst particles, and difficult to control the size, and achieve high performance. performance, the effect of avoiding oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

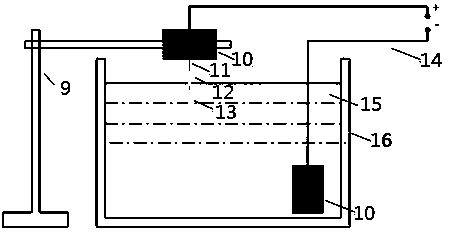

[0048] The method for preparing multicomponent alloy nanoparticles attached to carbon fibers in situ in a transmission electron microscope comprises the following steps:

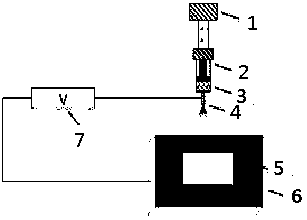

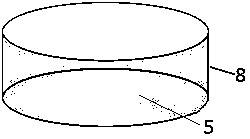

[0049] 1. In order to obtain carbon nanofibers, we use the method of electrospinning. in accordance with figure 1 The schematic diagram of electrospinning shown in the figure shows that before spinning, polyacrylonitrile (PAN) and dimethylformamide (DMF) are mixed according to a certain ratio to form a polymer solution and then loaded into the injector. Then place a substrate for carrying carbon nanofibers at a suitable position on the receiving screen directly opposite the injection port. Choose copper foil or carbon paper as the substrate, but according to experimental experience, due to the relatively high strength of copper foil compared with carbon paper, and weaker bonding with carbon fibers, it is easy to occur during spinning and post-heat treatment. The peeling and curling of carbon nanofibers, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com