Fat emulsion food supplement liquid and preparation method thereof

A technology for replenishing liquid and fat emulsion, applied in the fields of food preservation, food science, application, etc., can solve the problems of unstable carbon-carbon double bond chemical structure, easy to be oxidized, low storability of fish oil, etc., and achieve low cost of raw materials , the effect of increasing the content and improving the storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

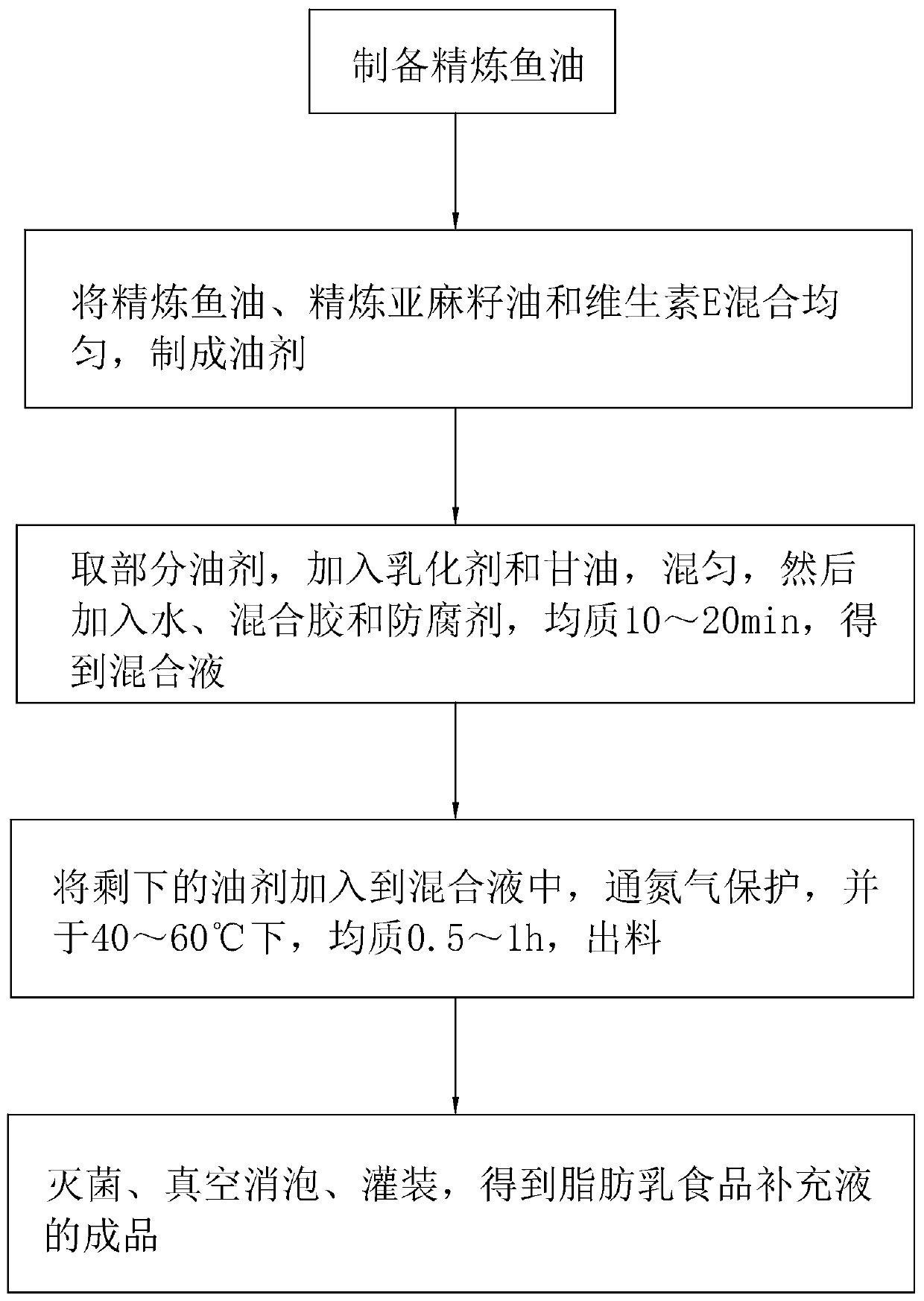

[0045] Example 1: A fat milk food supplement, the components and their corresponding mass percentages are shown in Table 1, and are prepared through the following steps:

[0046] Step 1, uniformly mixing refined fish oil, refined linseed oil with an ALA content of 60% and vitamin E to make an oil preparation;

[0047] Step 2: Take 10% oil, add Tween 80 and glycerin, mix evenly, then add water, gum arabic, tragacanth and sodium benzoate, and use a homogenizer to homogeneously mix at room temperature for 20 minutes to obtain a mixed solution;

[0048] Step 3, add the remaining 90% oil agent to the mixed liquid in Step 2, pass through nitrogen protection, and use a homogenizer to homogenize for 0.5h at a temperature of 50°C, and discharge;

[0049] Step 4, sterilizing, vacuum defoaming, and filling to obtain the finished product of fat milk food supplement;

[0050] Wherein the refined fish oil is prepared by the following steps:

[0051] Add invertase to the mixture of ethyl e...

Embodiment 2-6

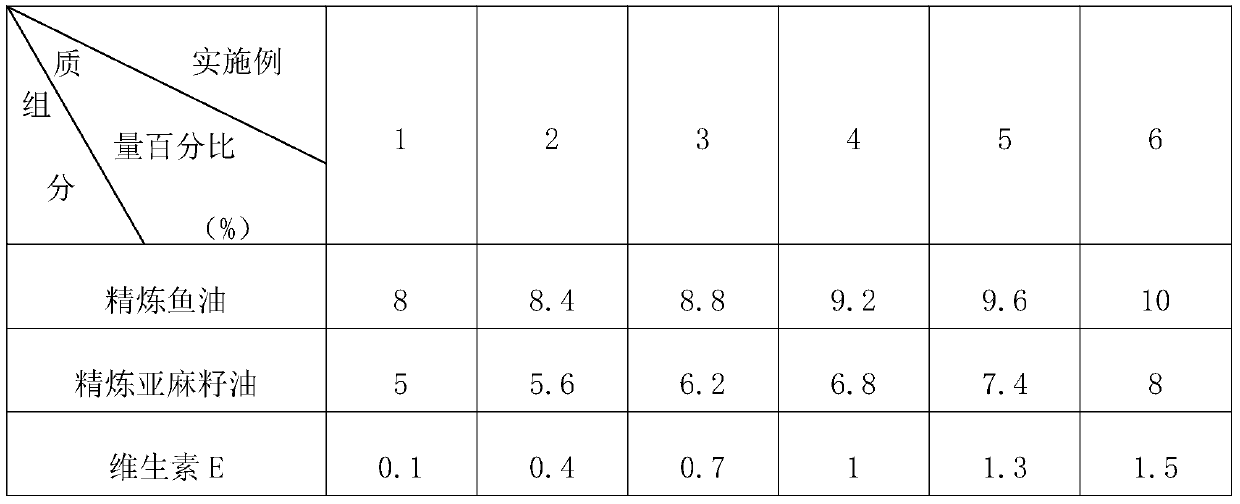

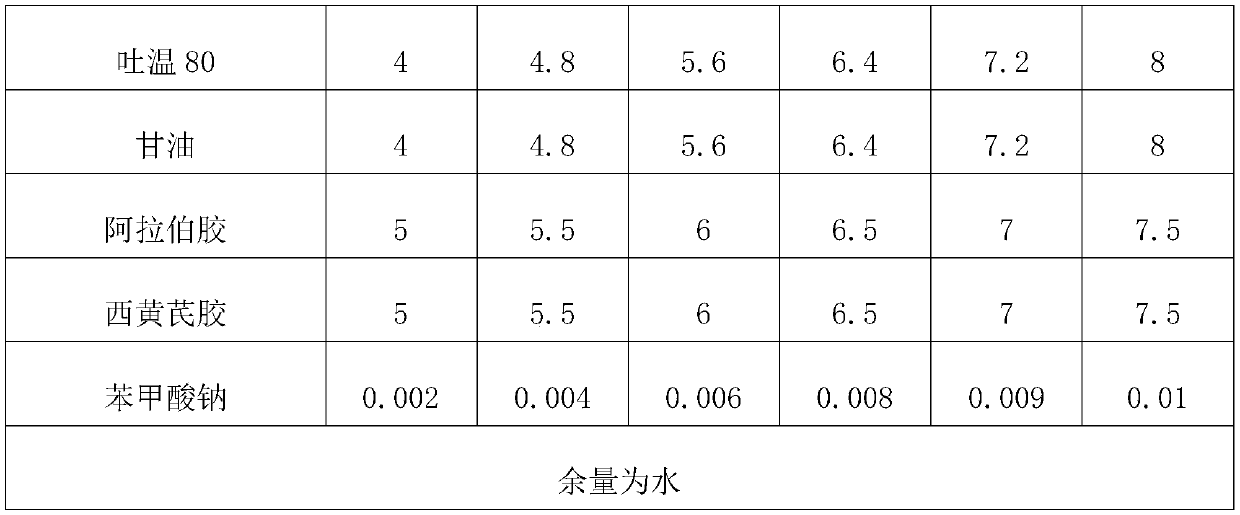

[0053] Example 2-6: A fat milk food supplement, the difference from Example 1 is that the components and their corresponding mass percentages are shown in Table 1.

[0054]Each component and its mass percentage content in table 1 embodiment 1-6

[0055]

[0056]

Embodiment 7

[0057] Embodiment 7: A fat milk food supplement, the difference from Embodiment 1 is that the refined fish oil is prepared by the following steps:

[0058] Add invertase to the mixture of ethyl ester type fish oil and glycerin, protect it with nitrogen, heat in a water bath at 50°C, react for 18 hours, add EPA and DHA to obtain refined fish oil, in which EPA, DHA and DPA in refined fish oil Content by mass percentage: 50%, 20% and 2.5%;

[0059] In this embodiment, the invertase adopts lipase 2000L (K) produced by Novozymes, the mass percentage is 8%, and the mass ratio of ethyl ester type fish oil to glycerin is 1:5;

[0060] All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com