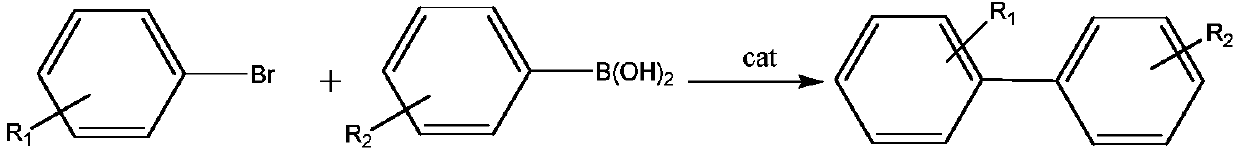

Supported nano Pd/MgO catalyst and method of preparing biphenyl compound from catalyst

A catalyst and supported technology, applied in the direction of physical/chemical process catalysts, hydrocarbons, hydrocarbons, etc., can solve the problems of difficult product separation, air and water sensitivity, etc., and achieve low price, reduced reaction time, and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] This embodiment provides the Pd / MgO catalyst (hereinafter referred to as Pd / MgO catalyst) that is used for the Suzuki coupling reaction. Be divided into palladium; The mass percentage composition of palladium in the described catalyst is 3%; The preparation method of present embodiment catalyst comprises the following steps:

[0018] Step 1: Weigh 0.06g of palladium chloride and put it in a round bottom flask, then weigh 0.04g of sodium chloride and put it in the flask, add 5ml of distilled water. Stirring was continued for 5 h at room temperature, and palladium chloride was dissolved to prepare a sodium chloropalladate solution.

[0019] Step 2: take by weighing 1g nanometer magnesium oxide (specific surface area is 600m 2 / g) add the sodium chloropalladate solution described in step one. Stir at room temperature for 1 h until the mixture is homogeneous.

[0020] Step 3: Measure 0.15 g of ethylene glycol as a reducing agent and add it to the slurry described in Step...

Embodiment 2

[0024] Add 1mmol of bromobenzene, 1.1mmol of phenylboronic acid, 2mmol of potassium carbonate, 0.0003mmol of Pd / MgO catalyst in terms of palladium element, and 3ml of water into a three-necked flask connected with a condenser. The reaction was carried out at a reaction temperature of 85° C. for 25 minutes. After the reaction, a sample was taken for HPLC analysis. The conversion rate of bromobenzene was 84%, and the product biphenyl was obtained.

Embodiment 3

[0026] Add 1mmol of bromobenzene, 1.1mmol of phenylboronic acid, 2mmol of potassium carbonate, 0.5mmol of tetrabutylammonium bromide, 0.0003mmol of Pd / MgO catalyst in terms of palladium, and 3ml of water into a three-necked flask connected to a condenser. The reaction was carried out at a reaction temperature of 85° C. for 25 minutes. After the reaction, a sample was taken for HPLC analysis. The conversion rate of bromobenzene was 99%, and the product biphenyl was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com