Production method of coking crude phenol by cyclic decomposition by gas and co-producing light calcium carbonate

A technology for coking crude phenol and gas circulation, applied in chemical instruments and methods, organic chemistry, calcium carbonate/strontium/barium, etc. The effect of reducing equipment corrosion and extending the operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

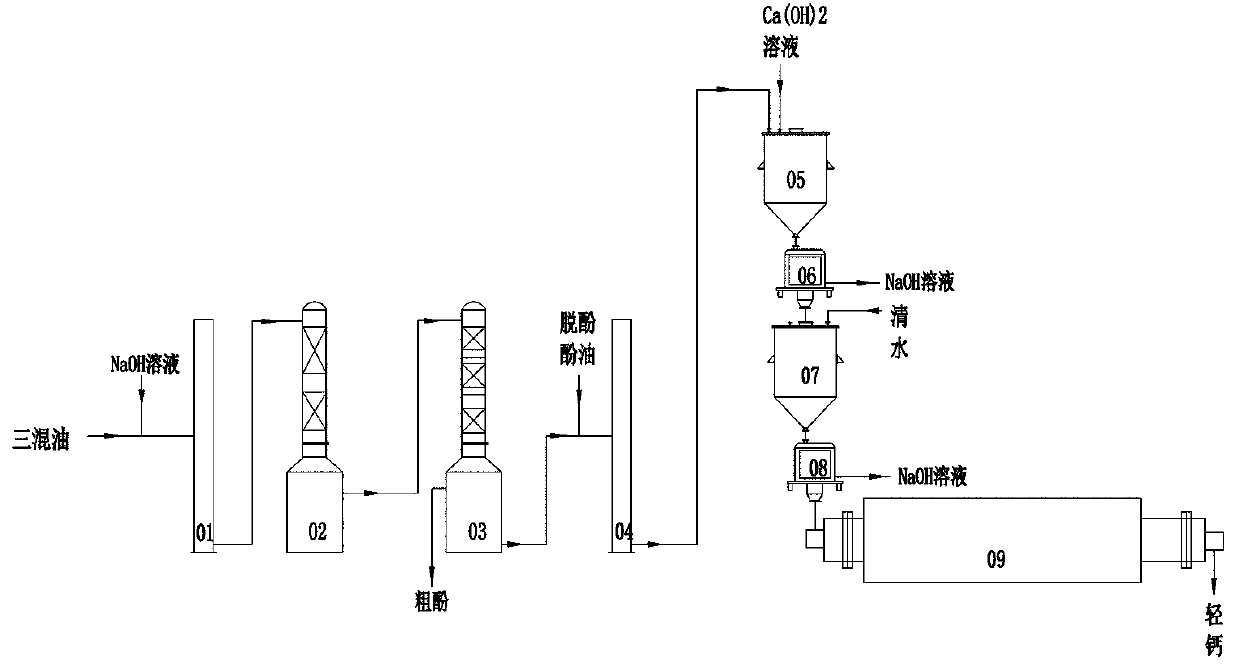

Image

Examples

Embodiment Construction

[0033] specific implementation plan

[0034] The present invention specifically comprises the steps:

[0035] (1) High-temperature coal tar is distilled to obtain a mixed fraction of phenol oil, naphthalene oil, and washing oil with a phenol content of about 4%-6%, which is washed with NaOH aqueous solution, and NaOH reacts with phenolic substances to form a sodium phenolate solution. The sodium phenol salt solution with a temperature of 60°C-80°C and a concentration of 25% is transported to the upper part of the primary decomposition tower with two layers of polypropylene rosette packing at a flow rate of 4000-5000 kg / h, and flows through the packing layer from top to bottom , with the rising cycle gas (active component CO 2 ) reverse contact, the CO entering the primary decomposition tower (02) 2 Concentration control is about 16--22%; most of the phenol sodium salt is decomposed by CO2 in the circulating gas to generate crude phenol and sodium carbonate (Na 2 CO 3 ) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com