Process for preparing heat-conducting polymer material by utilizing SLS to form porous ceramic heat-conducting network

A technology of thermally conductive polymers and porous ceramics, which is applied in the fields of automobile manufacturing, aerospace, and polymer materials. It can solve the problems of mechanical properties and processing properties, pores, and thermal conductivity. It can solve the problem of dispersion of fillers and The problem of the construction of the heat conduction network, the dispersion of fillers is fully controllable, and the effect of improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

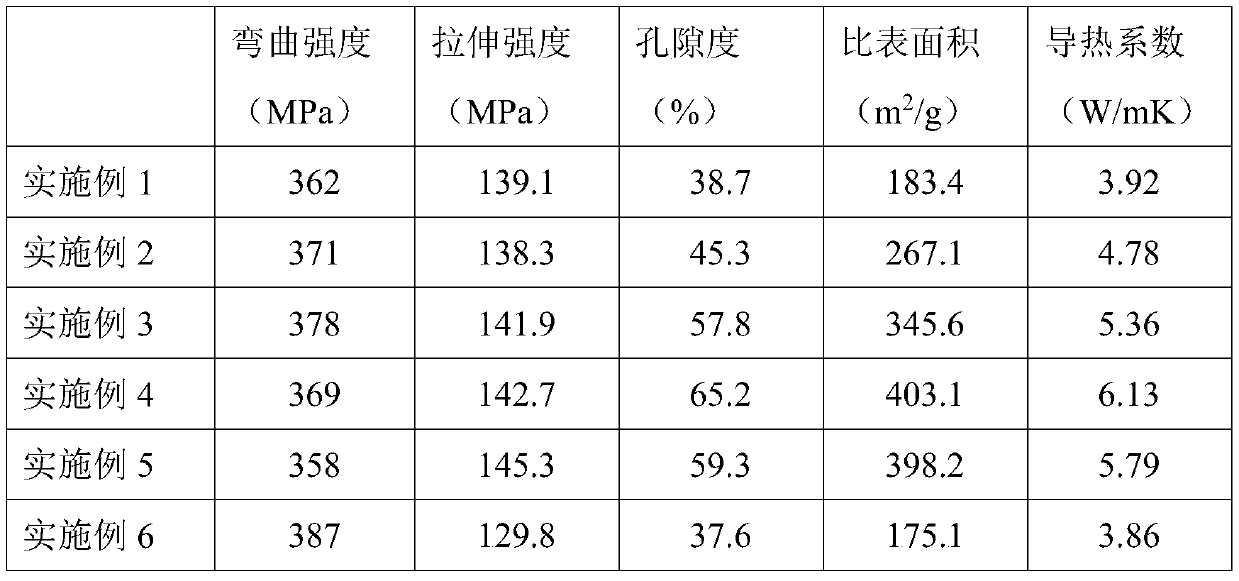

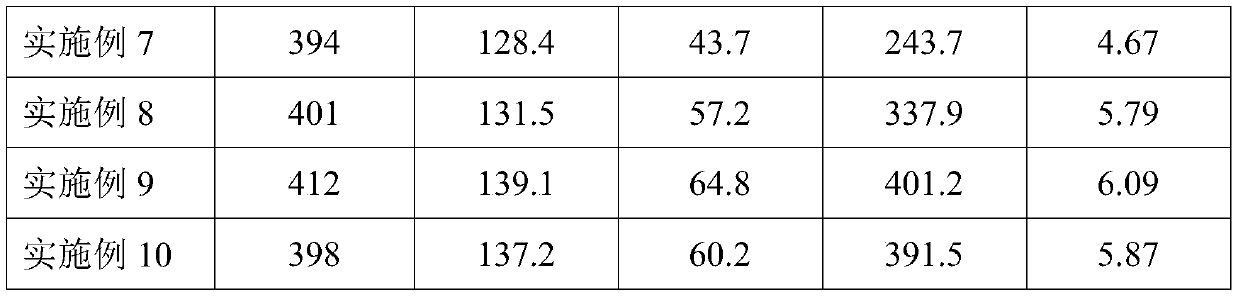

Examples

Embodiment 1

[0044] (1) Measure the boron nitride powder and PA12 powder with a plastic measuring cup, the volume ratio is 1:1, and mix with a high-speed mixer for 20 minutes.

[0045] (2) Import the designed integrated packing structure into the software, set the process parameters of SLS, mold cavity temperature is 150℃, printing surface temperature is 150℃, laser power is 10W, scanning speed is 600mm / s, and then proceed Printing and molding.

[0046] (3) Spray the epichlorohydrin solution on the obtained porous ceramic thermally conductive network 3 to 5 times, and dry at 120°C. Place the dried porous ceramic heat-conducting network in a muffle furnace and heat up from room temperature to 400°C at a rate of 10°C / min. After holding for 30 minutes, heat it up from 400°C to 900°C at a rate of 10°C / min. After 10 minutes, let it cool naturally.

[0047] (4) Weigh 45% by weight of bisphenol A epoxy resin, 25% by weight of phenolic resin, 20% by weight of curing agent and accelerator, heat, melt an...

Embodiment 2

[0049] (1) Measure boron nitride powder and PA12 powder with a plastic measuring cup, with a volume ratio of 1:1.5, and mix them with a high-speed mixer. The mixing time is 20 minutes.

[0050] (2) Import the designed integrated packing structure into the software, set the process parameters of SLS, mold cavity temperature is 155℃, printing surface temperature is 160℃, laser power is 12W, scanning speed is 600mm / s, and then proceed Printing and molding.

[0051] (3) Spray the epichlorohydrin solution on the obtained porous ceramic thermally conductive network 3 to 5 times, and dry at 120°C. Place the dried porous ceramic heat-conducting network in a muffle furnace and heat up from room temperature to 400°C at a rate of 10°C / min. After holding it for 40 minutes, heat it up from 400°C to 1000°C at a rate of 20°C / min. After 10 minutes, let it cool naturally.

[0052] (4) Weigh 48wt% of bisphenol A epoxy resin, 22wt% of phenolic resin, 20wt% of curing agent and accelerator, heat, melt ...

Embodiment 3

[0054] (1) Measure the boron nitride powder and PA12 powder in a plastic measuring cup with a volume ratio of 1:2, and mix them with a high-speed mixer for 30 minutes.

[0055] (2) Import the designed integrated packing structure into the software, set the process parameters of SLS, mold cavity temperature is 160℃, printing surface temperature is 160℃, laser power is 14W, scanning speed is 650mm / s, and then proceed Printing and molding.

[0056] (3) Spray the epichlorohydrin solution on the obtained porous ceramic thermally conductive network 3 to 5 times, and dry at 120°C. Place the dried porous ceramic heat-conducting network in a muffle furnace, and heat up from room temperature to 400°C at a rate of 10°C / min. After holding it for 40 minutes, heat it up from 400°C to 1100°C at a rate of 20°C / min. After 10 minutes, let it cool naturally.

[0057] (4) Weigh 50wt% of bisphenol A epoxy resin, 20wt% of phenolic resin, 20wt% of curing agent and accelerator, heat, melt and stir them, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com