Outdoor high weather resistant waterborne wood wax oil and preparation method thereof

A high weather resistance, wood wax oil technology, applied in wax coatings, coatings, rosin coatings, etc., can solve the problems of reduced environmental protection performance and insufficient weather resistance of wood wax oil, and achieve moderate hardness, good weather resistance and performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

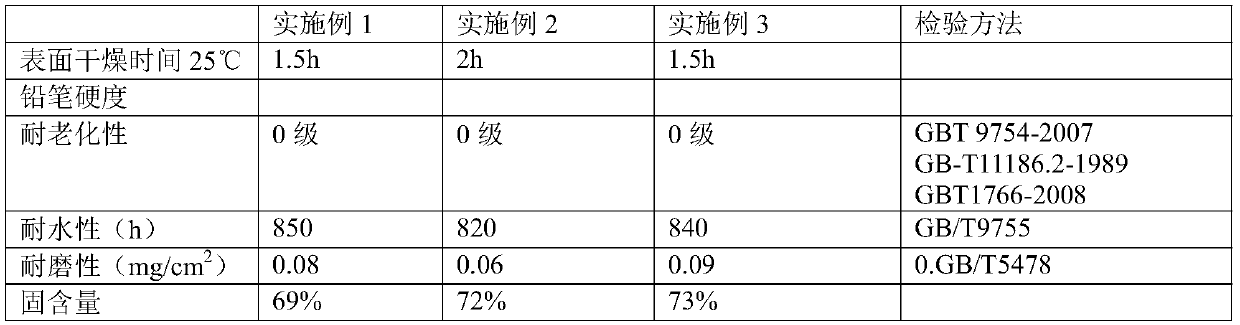

Examples

Embodiment 1

[0024] An outdoor high-weather-resistant water-based wood wax oil, its raw materials include the following components in parts by weight:

[0025] 60 parts of modified and unmodified vegetable oil, 8 parts of rosin resin and alkyd resin in equal proportions, 3 parts of β-terpene resin, 15 parts of carnauba wax, 2 parts of microcrystalline wax, 0.5 part of ricinoleic acid, and dry 0.5 part of anti-skinning agent, 0.3 part of anti-skinning agent, 0.1 part of defoamer, 0.5 part of ultraviolet absorber, and 1 part of nano titanium dioxide.

[0026] The vegetable oil is a mixture of linseed oil and one of tung oil, walnut oil, cottonseed oil, sunflower oil and soybean oil. The ratio of modified and unmodified vegetable oil was 2:1. The specific method of modifying vegetable oil is as follows: choose linseed oil with a linoleic acid content of 70%-80% and mix it with one of tung oil, walnut oil, cottonseed oil, sunflower oil and soybean oil, and mix the linseed oil with another kin...

Embodiment 2

[0033] An outdoor high-weather-resistant water-based wood wax oil, its raw materials include the following components in parts by weight:

[0034] 80 parts of modified and unmodified vegetable oil, 5 parts of rosin resin and alkyd resin in equal proportions, 5 parts of β-terpene resin, 10 parts of candelilla wax, 5 parts of microcrystalline wax, 0.1 part of ricinoleic acid, catalyst 1 part of dry agent, 0.1 part of anti-skinning agent, 0.5 part of defoamer, 0.1 part of ultraviolet absorber, and 3 parts of nano titanium dioxide.

[0035] The vegetable oil is a mixture of linseed oil and one of tung oil, walnut oil, cottonseed oil, sunflower oil and soybean oil. The ratio of modified and unmodified vegetable oil was 3:1. The specific method of modifying vegetable oil is as follows: choose linseed oil with a linoleic acid content of 70%-80% and mix it with one of tung oil, walnut oil, cottonseed oil, sunflower oil and soybean oil, and mix the linseed oil with another kind of Th...

Embodiment 3

[0042] An outdoor high-weather-resistant water-based wood wax oil, its raw materials include the following components in parts by weight:

[0043] 70 parts of modified and unmodified vegetable oil, 6 parts of rosin resin and alkyd resin in equal proportions, 4 parts of β-terpene resin, 12 parts of beeswax, 3 parts of microcrystalline wax, 0.4 part of ricinoleic acid, and 0.8 part of drier 0.2 part of anti-skinning agent, 0.1 part of defoamer, 0.4 part of ultraviolet absorber, 2 parts of nano titanium dioxide.

[0044]The vegetable oil is a mixture of linseed oil and one of tung oil, walnut oil, cottonseed oil, sunflower oil and soybean oil. The ratio of modified and unmodified vegetable oil was 3:1. The specific method of modifying vegetable oil is as follows: choose linseed oil with a linoleic acid content of 70%-80% and mix it with one of tung oil, walnut oil, cottonseed oil, sunflower oil and soybean oil, and mix the linseed oil with another kind of The weight ratio was 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com