Double negative curvature anti-resonance hollow-core optical fiber and preparation method thereof

A technology of hollow core fiber and anti-resonance, which is applied in the direction of glass fiber, cladding fiber, glass manufacturing equipment, etc. Problems such as insufficient use of boundary advantages, etc., to achieve the effect of being suitable for mass production, excellent structural symmetry, and good structural symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

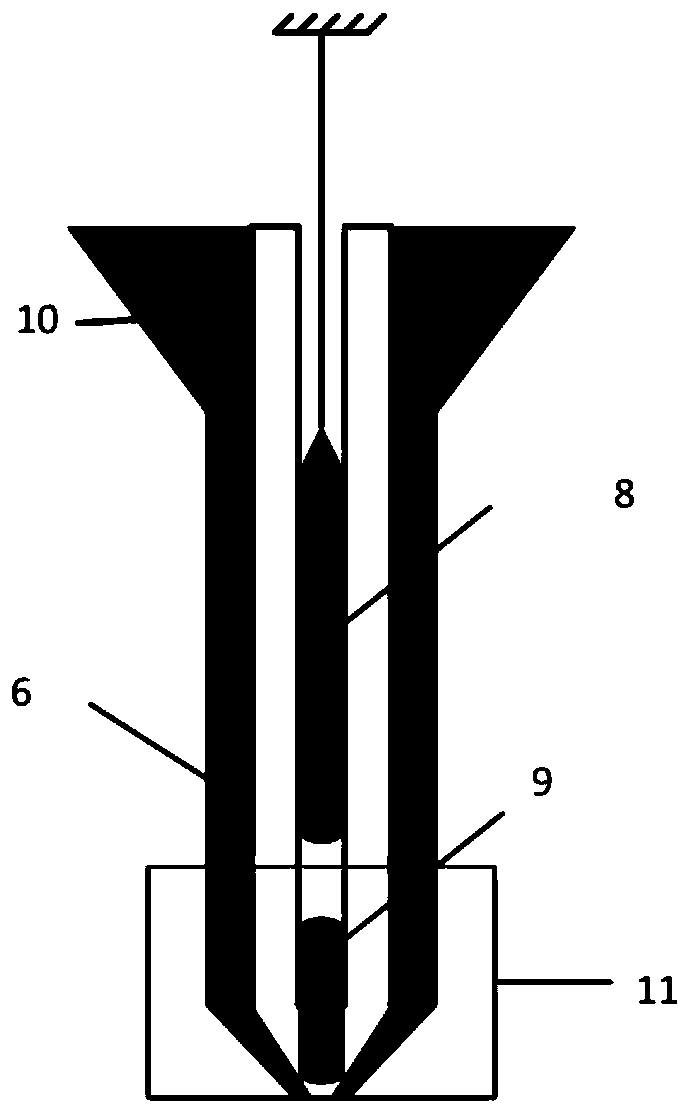

[0052] The present invention also provides a method for preparing a double negative curvature anti-resonant hollow-core optical fiber. The steps of the preparation method are as follows:

[0053] S1, capillary drawing: use the first glass tube to draw capillaries of two different radii, wherein, the number of capillaries of two different radii is the same and is multiple;

[0054] S2, preform assembly: use the second glass tube as the outer sleeve 6, draw one end of the outer sleeve 6 into a tapered shape, and then put capillaries of two different radii into the outer sleeve 6 in a staggered manner, wherein the capillary with a larger radius 4 close to the outer tube 6, the capillary 5 with a small radius is close to the capillary 4 with a large radius, and the capillary 5 with a small radius is closer to the center of the outer tube 6 than the capillary 4 with a large radius;

[0055] Two capillary rods of different lengths are used as the central mould, wherein the short cap...

Embodiment 1

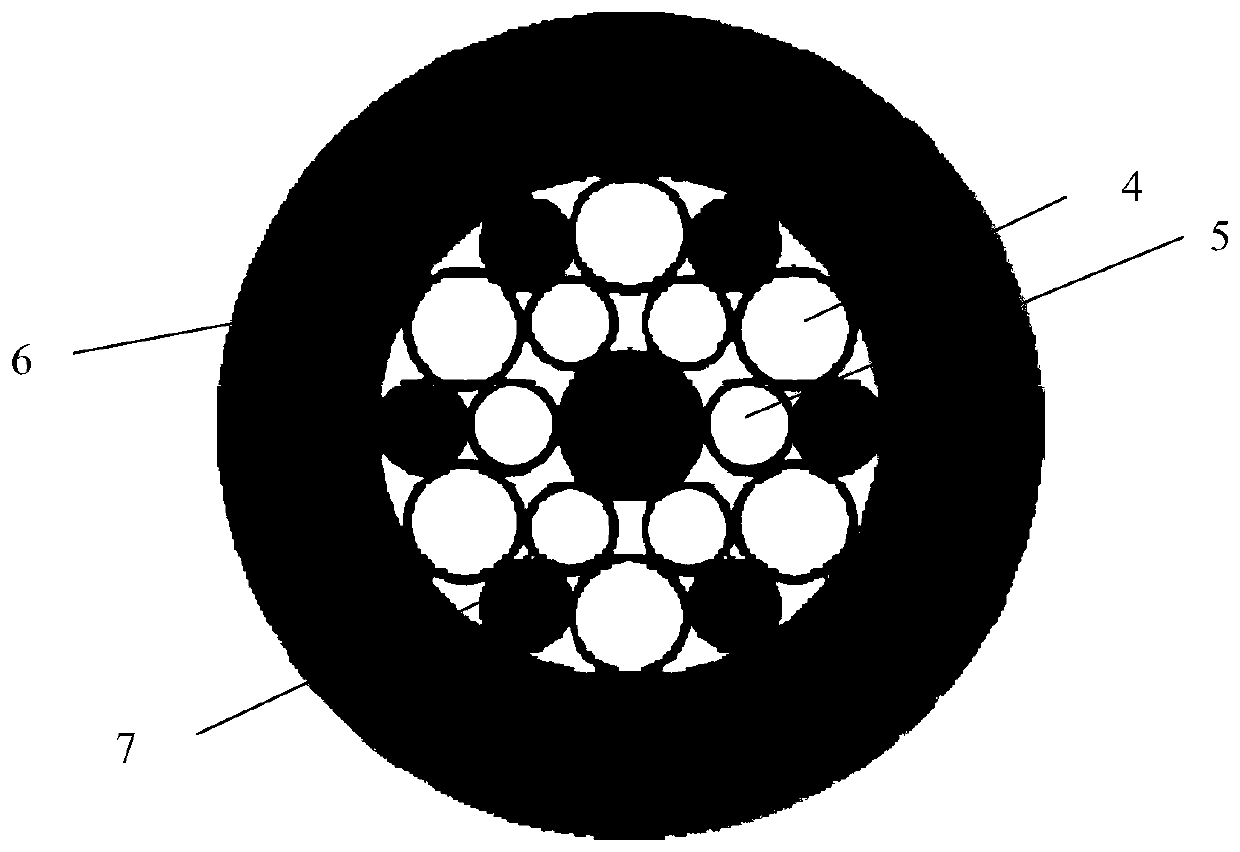

[0064] A double negative curvature anti-resonant hollow-core fiber, comprising a cladding region and a core region, the cladding region sequentially includes an outer cladding 1, a first anti-resonant layer and a second anti-resonant layer from outside to inside, wherein the first anti-resonant The resonant layer includes a plurality of rotationally symmetrically distributed first capillaries 2 and the first antiresonant layer is tangent to the outer cladding 1; the second antiresonant layer includes a plurality of rotationally symmetrically distributed second capillaries 3, and the second capillary 3 is connected to the first The capillaries 2 are tangential and staggered, the second anti-resonance layer is closer to the center line of the optical fiber than the first anti-resonance layer, and the irregular area surrounded by the boundary between the first anti-resonance layer and the second anti-resonance layer is In the core area with double negative curvature, the number of...

Embodiment 2

[0066] A method for preparing a double negative curvature antiresonant hollow-core optical fiber, comprising the following steps:

[0067] (1) Capillary drawing:

[0068] Use the first glass tube with a wall thickness of Φ50mm and a thickness of 2.5mm to draw capillaries of two different radii, both of which are 6 in number. , at a drawing furnace temperature of 1980°C, when drawing capillary tubes of two specifications, the internal pressures of the glass tubes were set to 2mabr and 5mbar respectively.

[0069] (2) Preform assembly:

[0070] Use a second glass tube with a wall thickness of Φ40mm and a wall thickness of 7.75mm and a length of 1000mm as the outer casing 6, draw one end of the outer casing 6 into a tapered shape, and the diameter of the inner hole at the tapered end is less than 5mm. Put the drawn capillaries of two different radii into the outer casing 6 in a staggered arrangement, wherein the capillary 4 with the larger radius is close to the outer casing 6,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com