Preparation method of fuel cell bipolar plate with flow channel

A fuel cell and bipolar plate technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of complex process flow, uneven conductivity distribution, high cost of metal bipolar plate molds, etc., to simplify the processing process, The effect of shortening processing time and reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In this example, graphite worms, carbon black and phenolic resin are used as conductive paste to make bipolar plates. The preparation method is as follows:

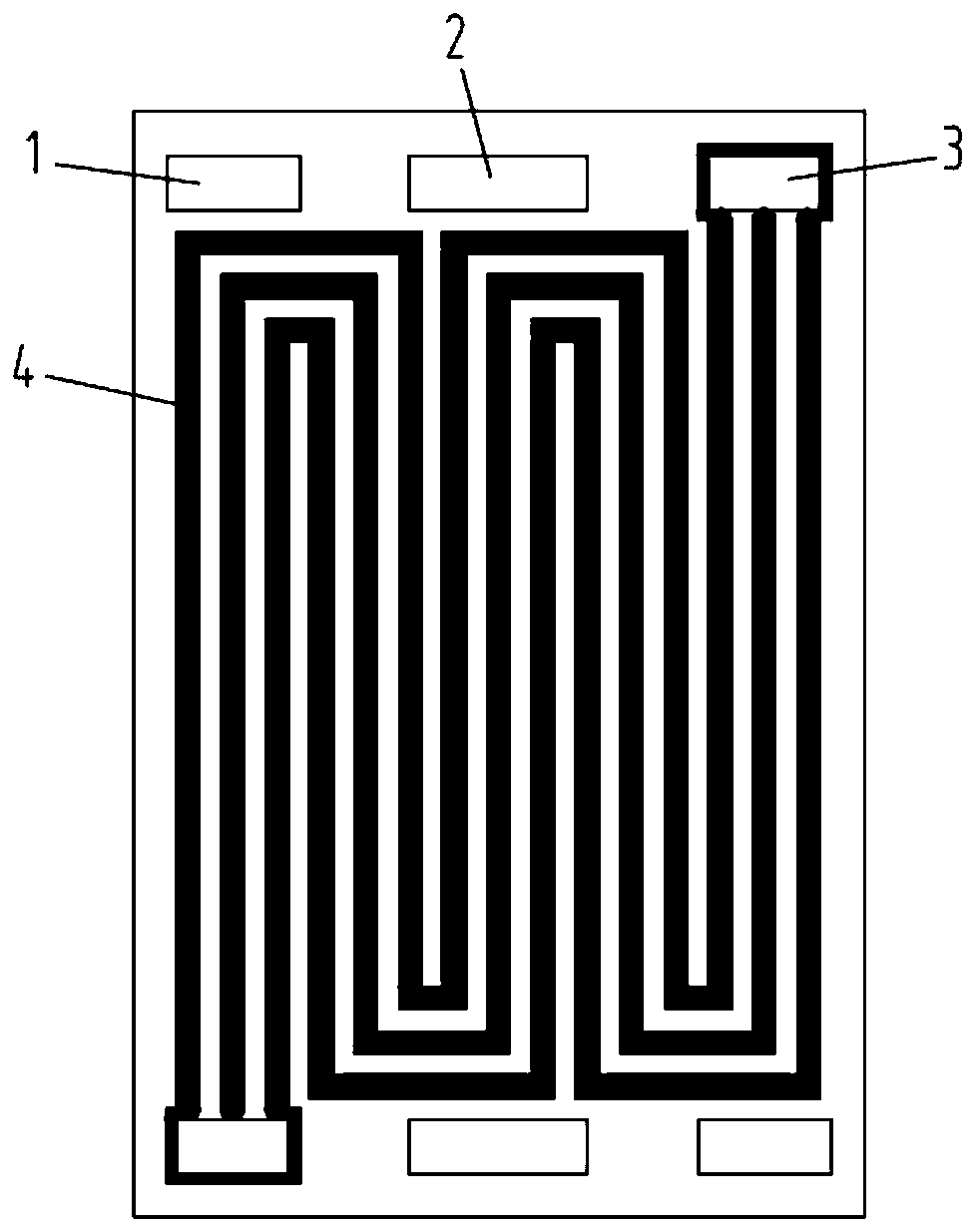

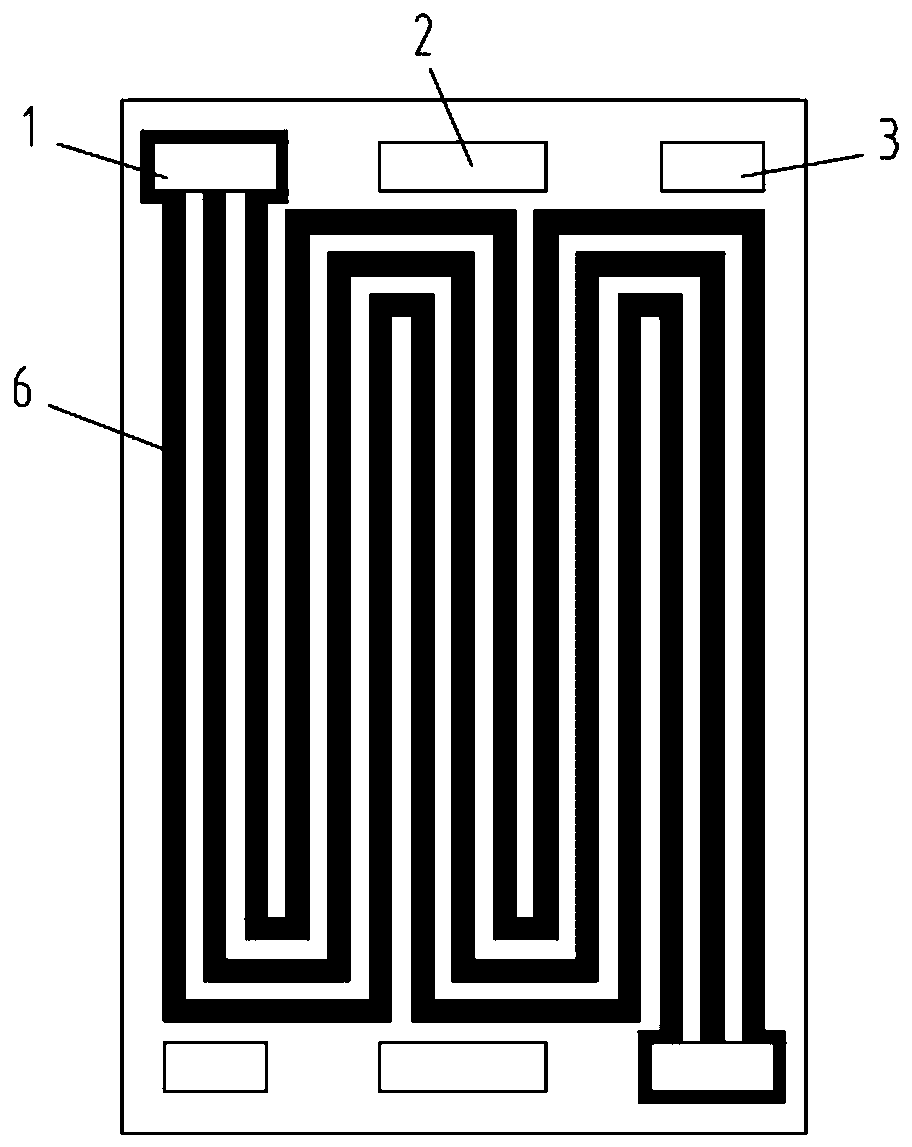

[0052] (1) Use 3D drawing software to draw the patterns of the anode flow field 4, cathode flow field 6 and coolant flow field 5 printed on the metal plate;

[0053] (2) Disperse graphite worms, carbon black, and phenolic resin in a solvent at a solid content ratio of 5:3:2 to obtain a uniform mixture and then dry it;

[0054] (3) The 3D printer moves the print head according to the printing path, draws several conductive paste tracks according to a specific pattern on one side of the first metal plate, and solidifies the conductive paste by heating to form a flow channel protruding from the surface of the metal plate Ridge; several flow channel ridges constitute a single-sided anode flow field 4 according to a specific pattern;

[0055] (4) The 3D printer moves the print head according to the printing path, draws...

Embodiment 2

[0059] In this embodiment, carbon black, carbon nanofibers, and phenolic resin are used as conductive pastes to make bipolar plates. The preparation method is as follows:

[0060] (1) Use 3D drawing software to draw the patterns of the anode flow field 4, cathode flow field 6 and coolant flow field 5 printed on the metal plate;

[0061] (2) Disperse carbon black, carbon nanofibers, and phenolic resin in a solvent at a solid content ratio of 6:2:2 to obtain a uniform mixture and then dry it;

[0062] (3) The 3D printer moves the print head according to the printing path, draws several conductive paste tracks according to a specific pattern on one side of the first metal plate, and solidifies the conductive paste by heating to form a flow channel protruding from the surface of the metal plate Ridge; several flow channel ridges constitute a single-sided anode flow field 4 according to a specific pattern;

[0063] (4) The 3D printer moves the print head according to the printing ...

Embodiment 3

[0067] In this example, titanium nitride and phenolic resin are used as conductive paste to make bipolar plates. The preparation method is as follows:

[0068] (1) Use 3D drawing software to draw the patterns of the anode flow field 4, cathode flow field 6 and coolant flow field 5 printed on the metal plate;

[0069] (2) Disperse titanium nitride and phenolic resin in a solvent at a solid content ratio of 9:1 to obtain a uniform mixture and then dry it;

[0070] (3) The 3D printer moves the print head according to the printing path, draws several conductive paste tracks according to a specific pattern on one side of the first metal plate, and solidifies the conductive paste by heating to form a flow channel protruding from the surface of the metal plate Ridge; several flow channel ridges constitute a single-sided anode flow field 4 according to a specific pattern;

[0071] (4) The 3D printer moves the print head according to the printing path, draws several conductive paste t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com