High-density plasma jet generating device based on reversed field configuration structure of current driving technology

A plasma and current-driven technology, applied in the direction of plasma, electrical components, etc., can solve the problems of unstable discharge stage of plasma source, plasma density, electron energy distribution, gas macroscopic temperature and uniformity that are difficult to meet the requirements at the same time, to achieve The effect of widening the range of operating parameters, avoiding unstable discharge phases, and increasing plasma density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

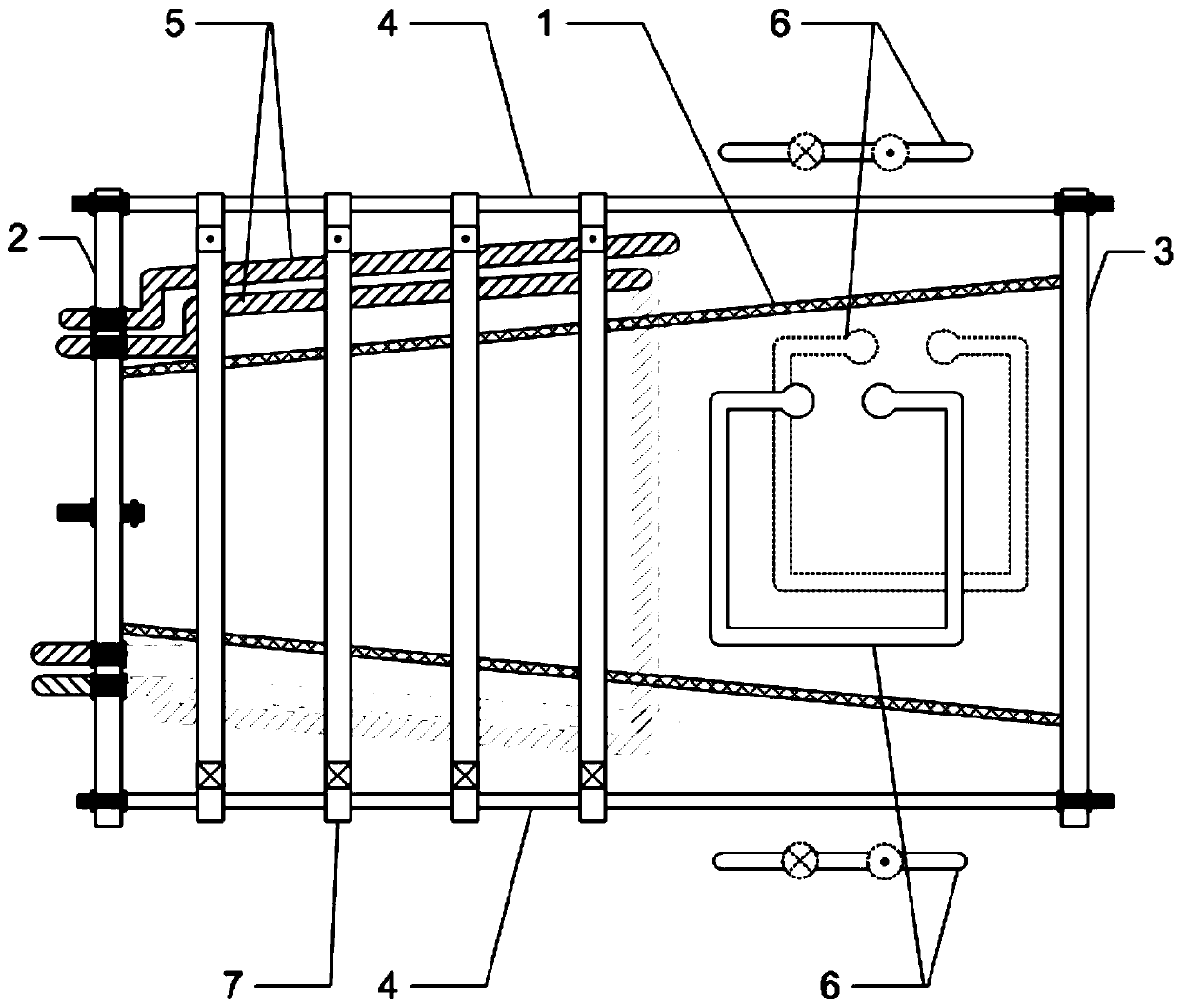

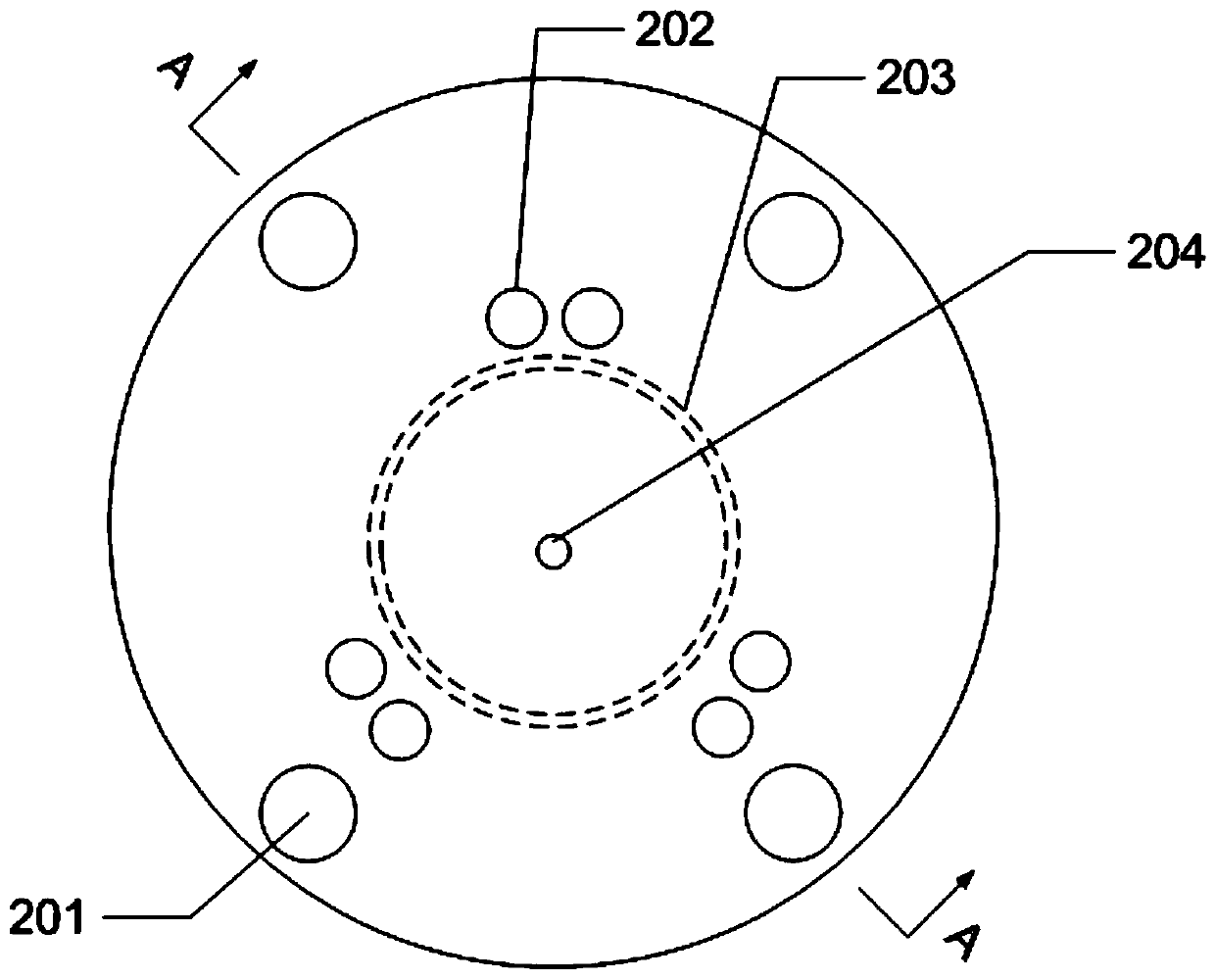

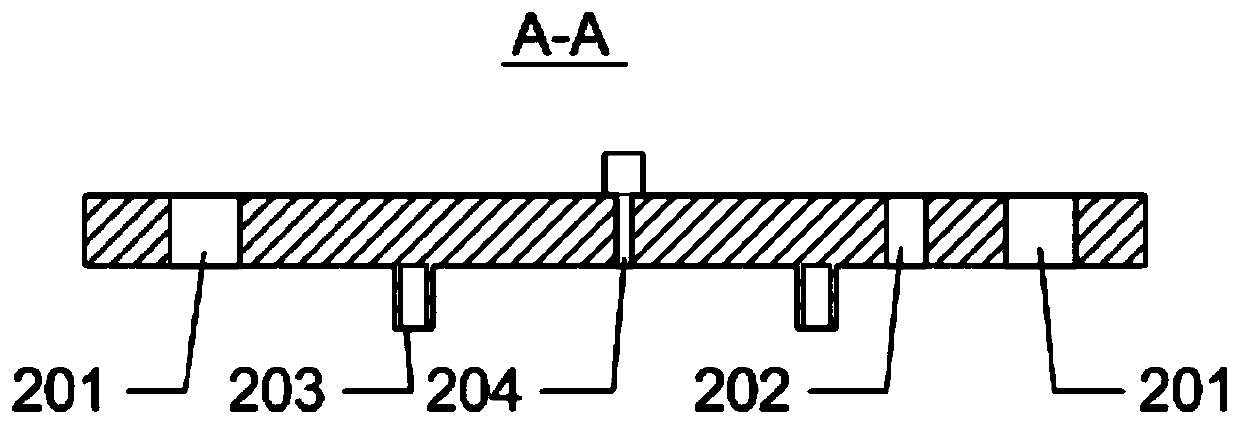

[0040] Embodiment: The vacuum chamber air chamber of the discharge device is composed of the small-end flange cover 2, the large-end flange cover 3 and the frustum-shaped quartz chamber 1, and the frustum-shaped quartz chamber 1 is connected to the small-end flange cover 2 with an outer diameter Φ=150mm, the outer diameter connected with the big end flange cover 3 is Φ=130mm, the wall thickness is d=5mm, and the height is h=300mm; the diameter of the small end flange cover 2 and the big end flange cover 3 is Φ = 330mm, 5mm thick circular No. 304 stainless steel plate; 4 round holes with a diameter of Φ = 8mm are evenly opened at the position of 20mm from the edge of the small end flange cover 2 and the large end flange cover 3, and a long rod is used to The bolts are strengthened; an air inlet hole 204 with a diameter of Φ=4mm is opened at the center of the left end cover to install the air nozzle for air intake; at the position of 10mm outside the connection end of the small e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com