Injection containing amino acid and sodium hyaluronate and preparation method of injection

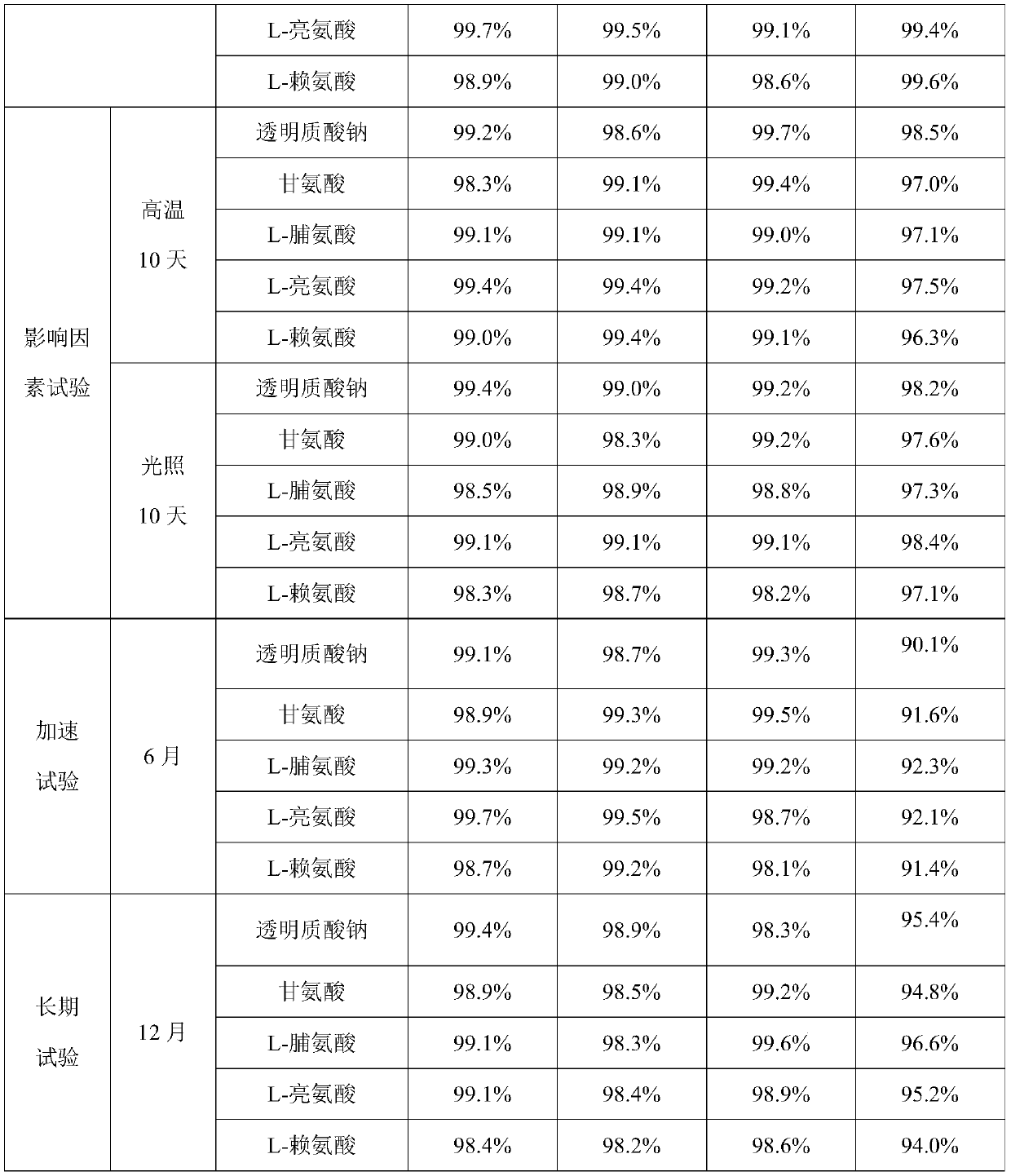

A technology of sodium hyaluronate and amino acid, applied in the fields of medical beauty and biomedicine, can solve the problems of poor stability of amino acid, easy degradation, and insignificant filling effect, and achieve the effect of no crystal precipitation, promotion of protein synthesis, and good clarity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

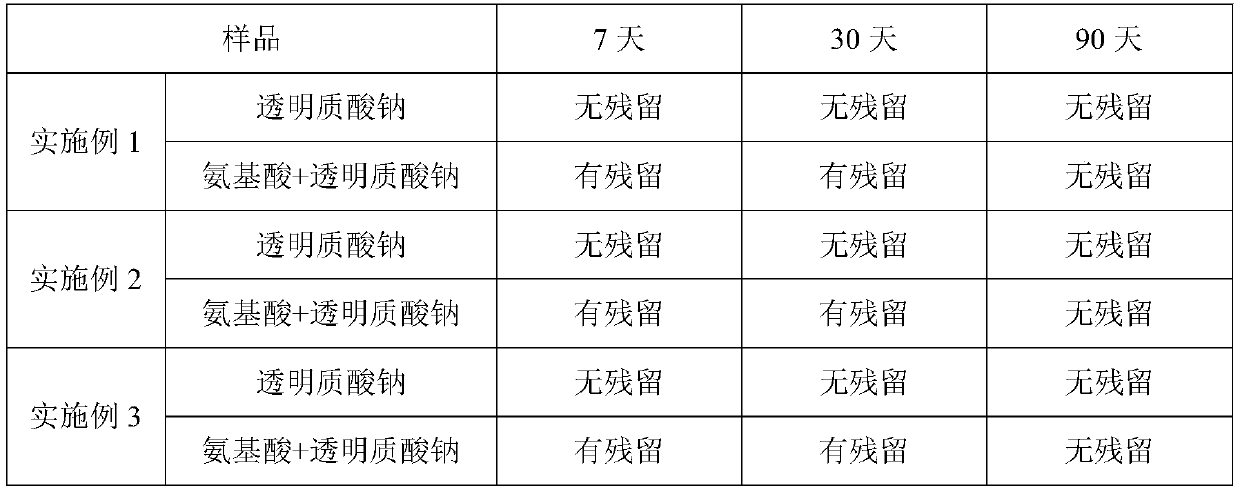

Embodiment 1

[0038] 1) Preparation of amino acid freeze-dried powder: Accurately weigh 4.0g of glycine, 1.2g of L-proline, 5.0g of L-leucine, and 4.5g of L-lysine, add 3000ml of water for injection to dissolve completely, and then add manna 9.0g of alcohol and 3.5g of dextran, stir evenly, adjust the pH of the solution to 6.5 with sodium hydroxide solution or hydrochloric acid solution, add 3g of activated carbon to filter, use a 0.22μm microporous membrane to filter the filtrate, and put the fine filtrate into a vial , 3ml per bottle, freeze-dried in a freezer to obtain freeze-dried amino acid powder.

[0039] 2) Preparation of sodium hyaluronate solution: Accurately weigh 50.0 g of sodium hyaluronate, add 1000 ml of phosphate buffer solution with a pH of 6.5 to dissolve, adjust the pH of the solution to 6.5 with 1 mol / L sodium hydroxide solution, stir well, and use 0.22 μm Filter through a microporous membrane to obtain a sodium hyaluronate solution.

Embodiment 2

[0041] 1) Preparation of amino acid freeze-dried powder: Accurately weigh 8.6g of glycine, 2.6g of L-proline, 10.0g of L-leucine, and 8.8g of L-lysine, add 3000ml of water for injection to dissolve completely, and then add manna 17.9g of alcohol and 7.2g of dextran, stir evenly, adjust the pH of the solution to 7.0 with sodium hydroxide solution or hydrochloric acid solution, add 6g of activated carbon to filter, use a 0.22μm microporous membrane to filter the filtrate, and put the fine filtrate into a vial , 3ml per bottle, freeze-dried in a freezer to obtain freeze-dried amino acid powder.

[0042] 2) Preparation of sodium hyaluronate solution: Accurately weigh 100.0 g of sodium hyaluronate, add 1000 ml of pH 7.0 phosphate buffer solution to dissolve, adjust the pH of the solution to 7.0 with 1mol / L sodium hydroxide solution, stir well, and use 0.22 μm Filter through a microporous membrane to obtain a sodium hyaluronate solution.

Embodiment 3

[0044] 1) Preparation of amino acid freeze-dried powder: Accurately weigh 14.0g of glycine, 4.5g of L-proline, 16.0g of L-leucine, and 14.0g of L-lysine, add 3000ml of water for injection to completely dissolve, and then add manna 28.5g of alcohol and 11.5g of dextran, stir evenly, adjust the pH of the solution to 5.5 with sodium hydroxide solution or hydrochloric acid solution, add 3g of activated carbon to filter, filter the filtrate with a 0.22μm microporous membrane, and put the fine filtrate into a vial , 3ml per bottle, freeze-dried in a freezer to obtain freeze-dried amino acid powder.

[0045] 2) Preparation of sodium hyaluronate injection: Accurately weigh 115.0 g of sodium hyaluronate, add 1000 ml of pH 5.5 phosphate buffer solution to dissolve, adjust the pH of the solution to 5.5 with 1 mol / L hydrochloric acid solution, stir well, and dissolve with 0.22 μm Pore membrane filtration to obtain sodium hyaluronate injection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com