Preparation method of colloidal ZnO/Au composite nanomaterials

A composite nanomaterial and colloid technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems affecting the physical and chemical properties of composite nanostructures, limit applications, and achieve excellent photocatalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

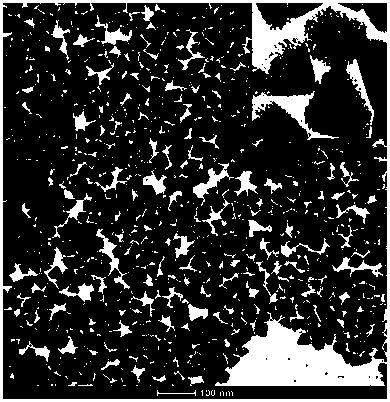

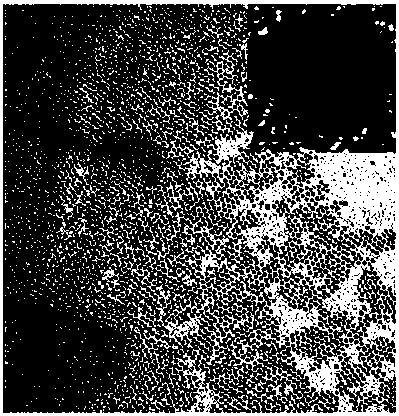

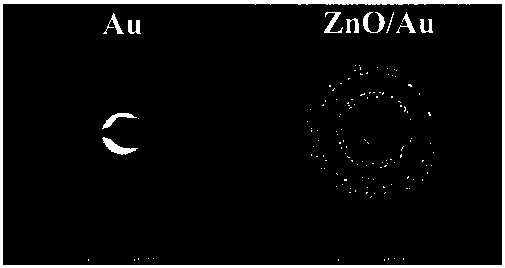

Image

Examples

Embodiment approach 1

[0019] (1) Mix 5 mL of oleylamine and 5 mL of tetralin evenly to obtain a mixed solvent; 2 Under protected conditions, 0.1 g of HAuCl 4 4H 2 O was fully dissolved in the mixed solution of oleylamine and tetralin to form precursor solution I; then, the mixed solution was heated to 25 °C by a water bath and maintained at this temperature for 10 min.

[0020] (2) Fully dissolve 0.5 mmol of tert-butylamine borane complex in 1 mL of oleylamine and 1 mL of tetralin mixed solution to form precursor solution II.

[0021] (3) Under ultrasonic conditions, 0.3 mmol of zinc acetate dihydrate was fully dissolved in 2 mL of oleylamine and 4 mL of dodecanol to form precursor solution III.

[0022] (4) Under the condition of magnetic stirring, the precursor solution II was injected dropwise into the precursor solution I, and kept at 25 °C for 1 h to obtain the colloidal solution IV.

[0023] (5) Add 10 mL of absolute ethanol to the colloidal solution IV; then, obtain the precipitate of Au ...

Embodiment approach 2

[0032] (1) Mix 5 mL of oleylamine and 5 mL of tetralin evenly to obtain a mixed solvent; under the conditions of magnetic stirring and nitrogen protection, 0.05 g of HAuCl 4 4H 2 O was fully dissolved in the mixed solution of oleylamine and tetralin to form precursor solution I; then, the mixed solution was heated to 10 °C by a water bath and maintained at this temperature for 10 min.

[0033] (2) Fully dissolve 0.2 mmol of tert-butylamine borane complex in 1 mL of oleylamine and 1 mL of tetralin mixed solution to form precursor solution II.

[0034] (3) Under ultrasonic conditions, 0.24 mmol of zinc acetate dihydrate was fully dissolved in 2 mL of oleylamine and 4 mL of dodecanol to form precursor solution III.

[0035] (4) Under the condition of magnetic stirring, the precursor solution II solution was injected into the precursor solution I dropwise, and the reaction was maintained at 10 °C for 1 h to obtain the colloidal solution IV.

[0036] (5) Add 10 mL of absolute eth...

Embodiment approach 3

[0040] (1) Mix 5 mL of oleylamine and 5 mL of tetralin evenly to obtain a mixed solvent; under the conditions of magnetic stirring and nitrogen protection, 0.15 g of HAuCl 4 4H 2 O was fully dissolved in the mixed solution of oleylamine and tetralin to form precursor solution I; then, the solution was placed in ice-water mixture for 10 min.

[0041] (2) Fully dissolve 0.6 mmol of tert-butylamine borane complex in 1 mL of oleylamine and 1 mL of tetralin mixed solution to form precursor solution II.

[0042] (3) Under ultrasonic conditions, 0.36 mmol of zinc acetate dihydrate was fully dissolved in 2 mL of oleylamine and 4 mL of dodecanol to form precursor solution III.

[0043] (4) Under the condition of magnetic stirring, the precursor solution II solution was quickly injected into the precursor solution I, and the reaction was maintained at 0 °C for 1 h to obtain the colloidal solution IV.

[0044] (5) Add 10 mL of absolute ethanol to the colloidal solution IV; then, obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com