Method for measuring liquid-phase saturation adsorption quantity of short-chain alcohol in microporous molecular sieve and adsorption isotherm

A microporous molecular sieve and short-chain alcohol technology, which is used in measuring devices, material absorption and weighing, material separation, etc., can solve the problems of small pressure range and low accuracy, so as to reduce experimental errors, reduce errors, and improve The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

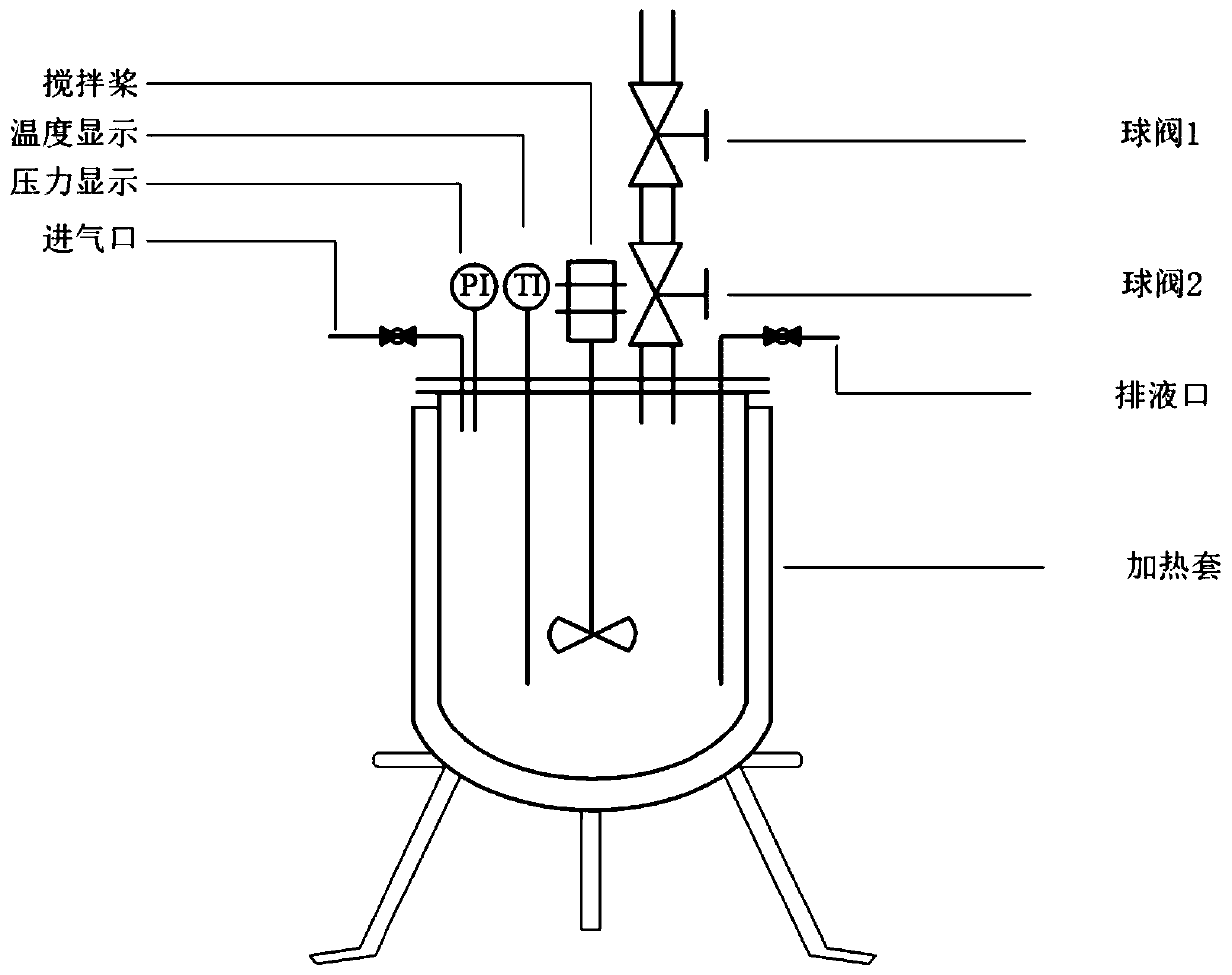

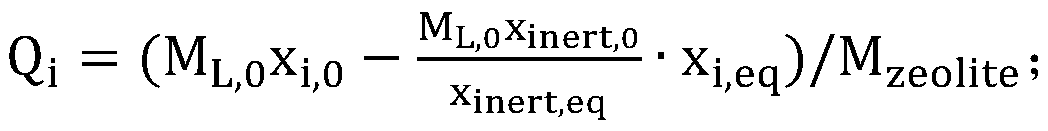

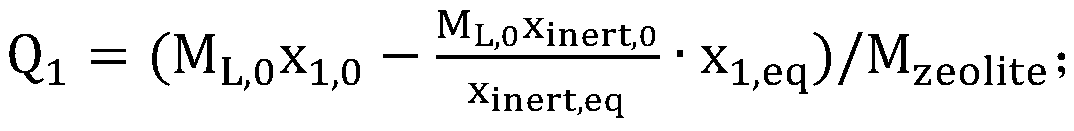

[0059] A method for measuring the saturated adsorption capacity of ethylene glycol on granular NaY molecular sieves, comprising the steps:

[0060] (1) Mixed solution preparation: select a component (benzhydryl alcohol) that is inert to NaY molecular sieve and ethylene glycol, and prepare completely miscible ethylene glycol and benzyl alcohol in a mass ratio of 1:1 as much as possible to form a mixed group points, placed as attached figure 1 In the reaction kettle shown, weigh and add the mixed component mass M in the kettle L,0 =40.04g, the complete miscible mixed components are sampled for gas chromatography quantitative analysis, showing that the mass fraction of ethylene glycol x i,0 =50.25%, inert component (benzhydryl alcohol) x inert,0 = 49.75%;

[0061] (2) Sample preparation: accurately weigh the mass M of the granular NaY molecular sieve zeolite =10.00g, close ball valve 2, open ball valve 1, place the weighed molecular sieve between ball valve 1 and ball valve 2...

Embodiment 2

[0065] The difference with Example 1 is that the inert component benzhydryl alcohol is replaced by 1-octanol, and the mixed component mass M is added to the kettle by weighing L,0 =40.02g, the mass fraction of ethylene glycol before the test adsorption x i,0 =50.36%, inert component (1-octanol) x inert,0 =49.64%, mass fraction of ethylene glycol x when testing adsorption equilibrium i,eq =29.85%, inert component (1-octanol) x inert,eq =70.15%, weighing granular NaY molecular sieve quality M zeolite =10.01g, calculate the saturated adsorption capacity of ethylene glycol on the NaY molecular sieve to be Q i = 1.169 g / g.

Embodiment 3

[0067] The difference with Example 1 is that the inert component benzhydryl alcohol is replaced by triethylene glycol, and the mixed component mass M is added to the kettle by weighing L,0 =39.99g, the mass fraction of ethylene glycol before the test adsorption x i,0 =50.08%, inert components (triethylene glycol) x inert,0 =49.92%, mass fraction of ethylene glycol x when testing adsorption equilibrium i,eq =29.34%, inert component (triethylene glycol) x inert,eq =70.66%, weighing granular NaY molecular sieve quality M zeolite =10.03g, calculate the saturated adsorption capacity of ethylene glycol on the NaY molecular sieve to be Q i = 1.170 g / g.

[0068] Examples 1-3 According to the comparative experiments of three different inert components, the saturated adsorption capacity of ethylene glycol on NaY molecular sieves at 60°C and 2.0MPa0+ was measured, and the standard deviation was 0.000959. The saturated adsorption capacity measured in three experiments Basically the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com