Ceramic binder cubic boron nitride cutter suitable for processing high temperature alloy

A technology of cubic boron nitride and ceramic adhesive, which is applied to lathe tools, manufacturing tools, metal processing equipment, etc., can solve problems such as tool wear and deformation, and achieve reduced cutting vibration, high melting point, and good electrical conductivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

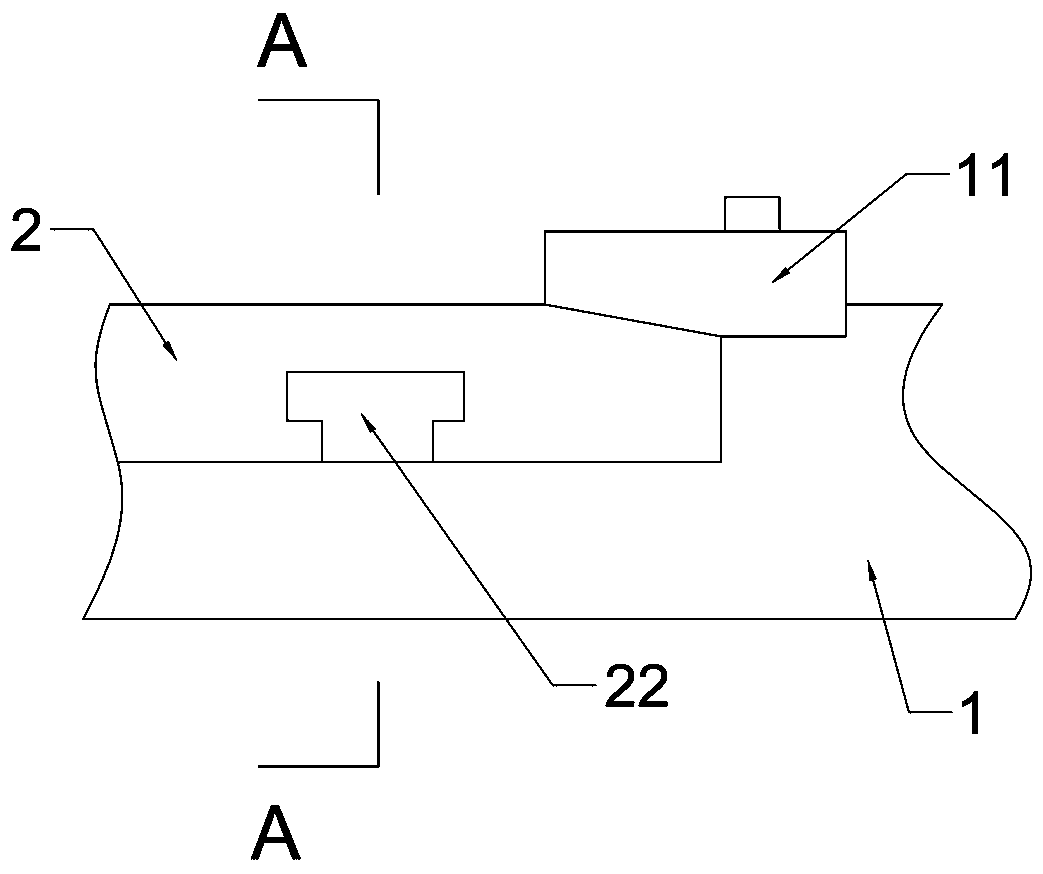

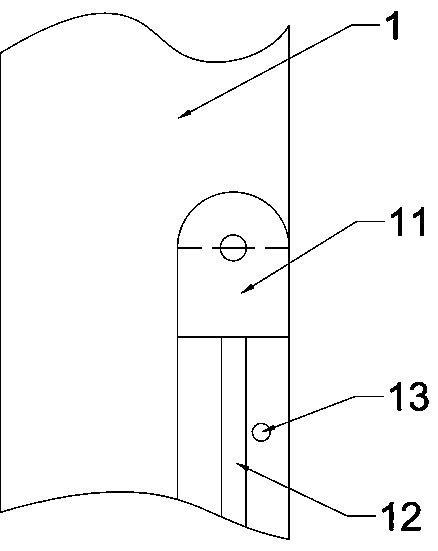

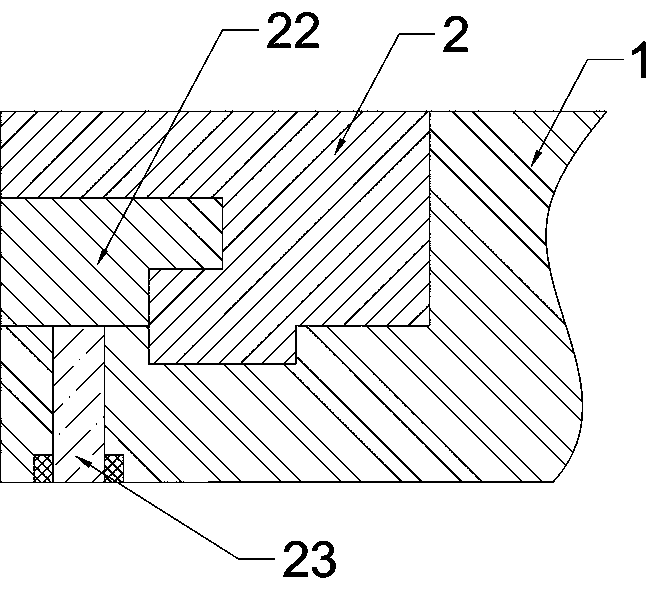

[0037] Such as Figure 1~6As shown, a ceramic binder cubic boron nitride tool suitable for processing superalloys includes a tool holder 1, a cutter base 2, a cubic boron nitride cutter head 3, an upper pressing plate 11 and a lower pressing plate 22, and the tool holder 1 An installation area is provided on the left end side of the tool bar 1, and the installation area is a rectangular platform recessed on the left end side of the cutter bar 1. The upper side of the rectangular platform and the adjacent two sides are not blocked, and the center of the bottom surface of the installation area is longitudinally provided with a Fixed groove 12, fixed groove 12 is a rectangular groove, the length of fixed groove 12 is not less than 1 / 2 of the installation area length, the length of fixed groove 12 is equal to 1 / 2 of the installation area length in the present embodiment. The outer middle part of the fixing groove 12 is provided with a circular fixing hole 13; the upper right side ...

Embodiment 2

[0041] A ceramic binder cubic boron nitride tool material suitable for processing high-temperature alloys is composed of cubic boron nitride powder and a binder. In terms of weight percentage, the cubic boron nitride powder accounts for 45%, and the binder accounts for 55%. The bonding agent is composed of the following raw materials in weight percentage: 5% of lanthanum oxide, 5% of zirconium oxide, 55% of aluminum oxide, and 35% of titanium nitride.

Embodiment 3

[0043] A ceramic binder cubic boron nitride tool material suitable for processing high-temperature alloys is composed of cubic boron nitride powder and a binder. In terms of weight percentage, cubic boron nitride powder accounts for 80%, and the binder accounts for 20%. The bonding agent is composed of the following raw materials in weight percentage: 2% of lanthanum oxide, 2% of zirconium oxide, 92% of aluminum oxide, and 4% of titanium nitride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com