Batch preparation method of nanometer cadmium hydroxide or nanometer cadmium oxide

A technology for cadmium hydroxide and cadmium oxide, which is applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve the problems of inability to batch prepare nano-cadmium hydroxide, uneven particle size distribution of nano-cadmium oxide, and complicated preparation process. , to achieve the effect of simple preparation process, uniform particle size and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

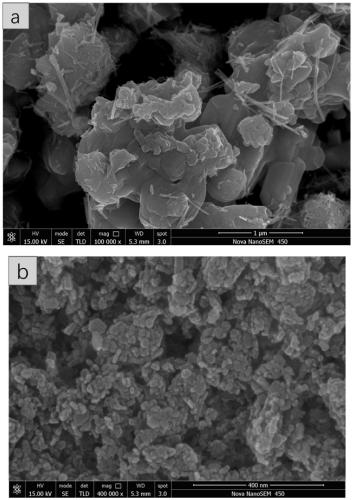

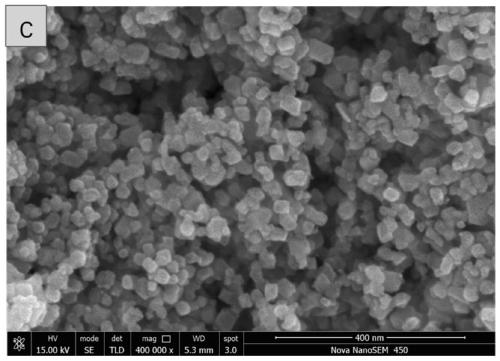

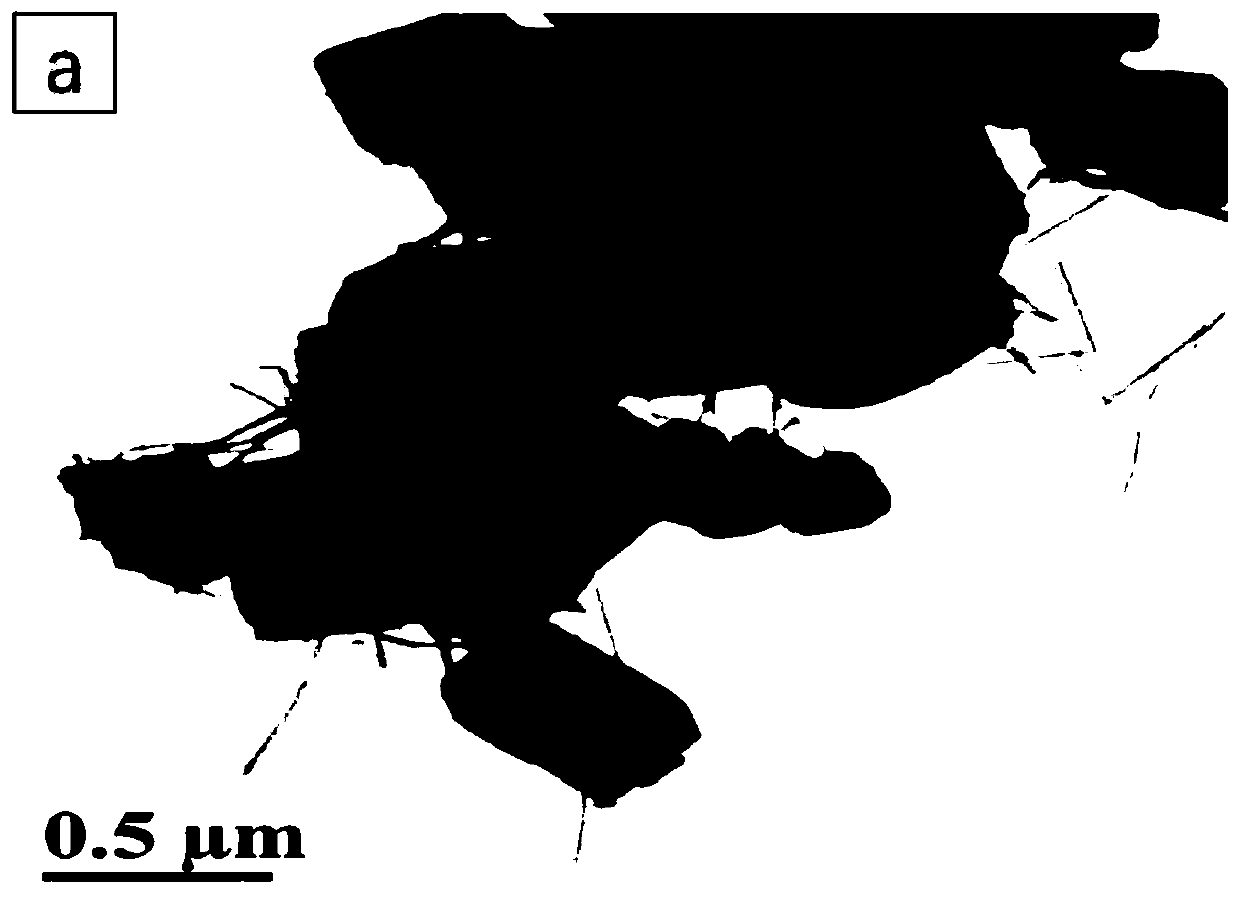

Image

Examples

preparation example Construction

[0025] The preparation method of nano cadmium hydroxide or nano cadmium oxide of the present invention, concrete steps are as follows:

[0026] The first step is to weigh 1-20kg of industrial product CdO, and configure a dispersion liquid. The mass ratio of water and ethanol in the dispersion liquid is water: ethanol is 9:1-1:1, and the mass ratio of CdO in the CdO slurry is 5-1. 15%, add industrial product CdO into the dispersion liquid for stirring and dispersing;

[0027] In the second step, add the dispersion liquid into the grinder, adjust the speed of the grinder to 800~1500rpm, and the feed rate to 4~10kg / min, repeat the grinding of the material, and repeat this process to crush CdO. The chiller cools down the grinding cylinder, controls the temperature of the grinding material below 30°C, and the number of grinding times is more than 30;

[0028] In the third step, the obtained nano-Cd(OH) 2 Slurry, nano Cd(OH) at room temperature 2 The slurry is settled for 12~48h,...

Embodiment 1

[0032] In the first step, 10kg of industrial product CdO is weighed, and 100kg of dispersant is configured. The dispersant adopts a mixed liquid with a mass ratio of water and ethanol of 7:3, and the industrial product CdO is added to the dispersant for stirring and dispersing to obtain a CdO dispersion;

[0033] In the second step, add the dispersion into the grinder, adjust the speed of the grinder to 1300rpm, and the feed rate to 4kg / min, repeat the grinding of the material, repeat this process to grind CdO, and grind it through an industrial chiller during the grinding process Cool down the cylinder, control the temperature of the grinding material at 25°C, and grind 50 times;

[0034] In the third step, the obtained nano-Cd(OH) 2 Slurry, nano Cd(OH) at room temperature 2 The slurry was settled for 12 hours, and the supernatant liquid was removed;

[0035] In the fourth step, the concentrated nano Cd(OH) 2 Put the slurry into a vacuum freeze dryer, set the pre-freezing ...

Embodiment 2

[0038] In the first step, 10kg of industrial product CdO is weighed, and 60kg of dispersant is configured. The dispersant adopts a mixed liquid with a mass ratio of water and ethanol of 7:3, and the industrial product CdO is added to the dispersant for stirring and dispersing to obtain a CdO dispersion;

[0039] In the second step, add the dispersion into the grinder, adjust the speed of the grinder to 1300rpm, and the feed rate to 4kg / min, repeat the grinding of the material, repeat this process to grind CdO, and grind it through an industrial chiller during the grinding process Cool down the cylinder, control the temperature of the grinding material at 25°C, and grind 50 times;

[0040] In the third step, the obtained nano-Cd(OH) 2 Slurry, nano Cd(OH) at room temperature 2 The slurry was settled for 12 hours, and the supernatant liquid was removed;

[0041] In the fourth step, the concentrated nano Cd(OH) 2 Put the slurry into a vacuum freeze dryer, set the pre-freezing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com