High-strength flame-retardation yarn and preparation method thereof and durable fabric

A durable fabric, high-strength technology, applied in the direction of yarn, application, clothing, etc., can solve the problems of poor flame retardancy, easy to stick to metal slag, low strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

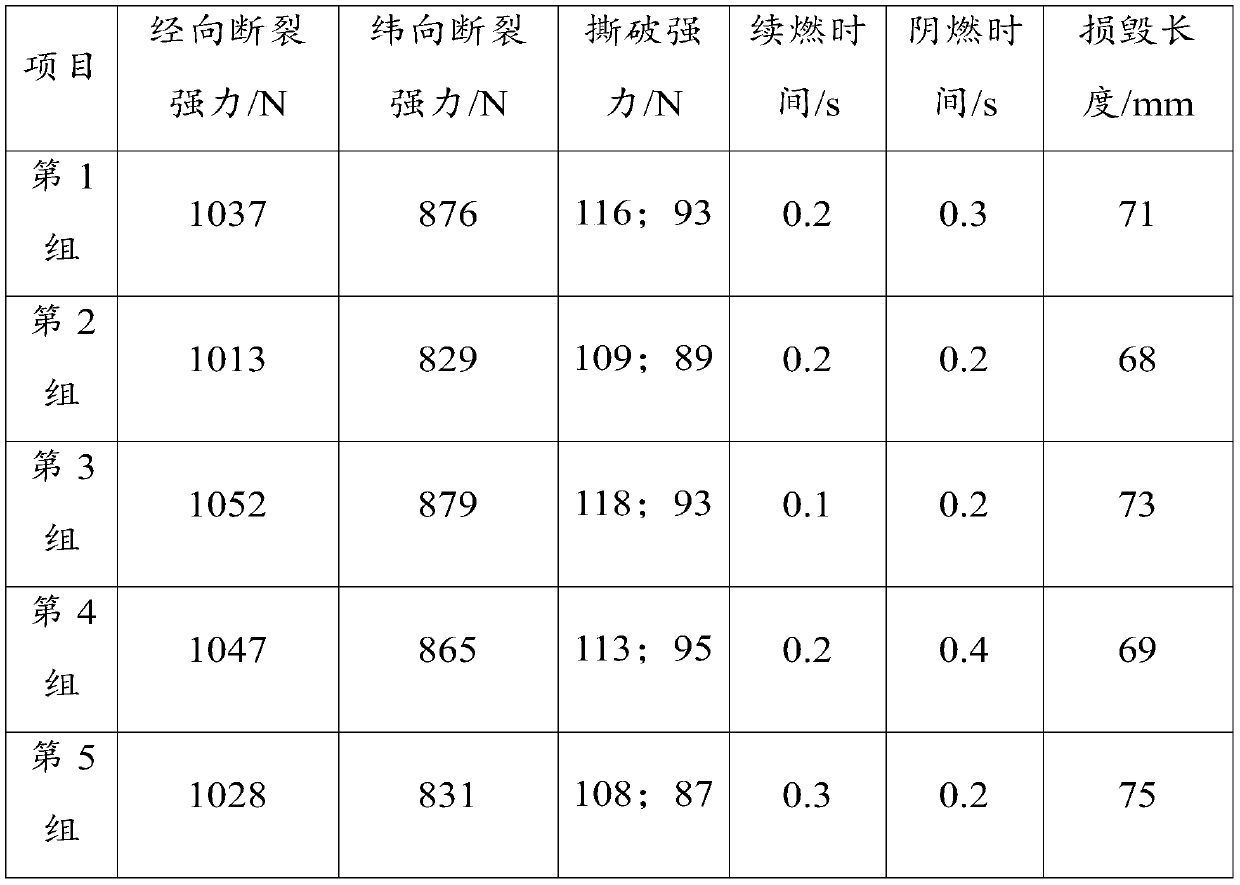

Examples

preparation example Construction

[0051] In the second aspect, the embodiment of the present application provides a method for preparing the high-strength flame-retardant yarn provided in the embodiment of the first aspect, comprising: covering the core filament with the outer covering fiber to obtain a single core-spun yarn. Among them, the type selection, composition and weight ratio of the core yarn and the outer fiber, as well as the specification, fineness, twist, twist direction, etc. of the yarn, all refer to the high-strength flame-retardant yarn provided by the embodiment of the first aspect. Let me repeat.

[0052] Exemplarily, the outer covering fiber is prepared by mixing raw materials, opening, cleaning, carding into tops, and then drawing.

[0053] In some optional embodiments, the outer covering fiber is produced by the following method: the raw material of the outer covering fiber is made into a wool top of 4-5g / 10m and then drawn.

[0054] Further optionally, the drawing process adopts the pr...

Embodiment 1

[0061] A durable fabric made from high tenacity flame retardant yarns woven on rapier looms and dyed. The durable fabric has a plain weave and a grammage of 190g / m 2 .

[0062] Among them, the high-strength flame-retardant yarn has a specification of 30s / 2 and a denier of 177D. The core yarn is polyester, the strength of the core yarn is 7cN / dtex, and the denier of the core yarn is 30D. The outer covering fiber is composed of 50wt% pyrophosphate flame retardant viscose, 38wt% silicon nitrogen flame retardant viscose and 12wt% polytetrafluoroethylene. The weight ratio of the core filament and the outer covering fiber is 20:80.

[0063] The preparation method of the high-strength flame-retardant yarn includes:

[0064] S1. Mix the raw materials of outsourcing fibers in proportion, open them loosely, and clear them, and then make 4.5g / 10m wool tops through one pass on the flat carding machine. Draw frame in 3 lanes to obtain outsourcing fibers.

[0065] S2. Feed the outsour...

Embodiment 2

[0067] A kind of durable fabric, its difference with embodiment 1 is that the grammage of this durable fabric is 160g / m 2 , the specification of the high-strength flame-retardant yarn is 34s / 2, the denier is 156D, and the denier of the core yarn is 20D.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com