Preparation method of core-shell structure silicon dioxide spherical nanoparticles

A technology of core-shell structure and silica, applied in the direction of silica, silica, etc., can solve the problems of high preparation cost and complicated method, and achieve the effect of simple preparation, simple operation method and large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

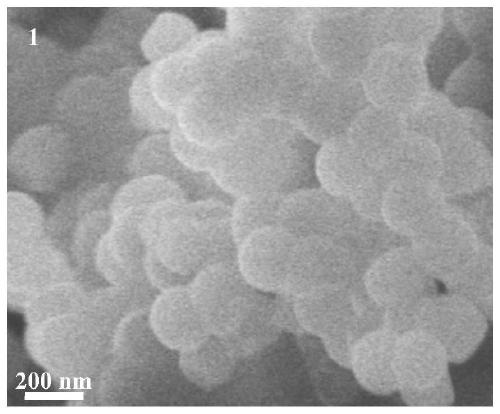

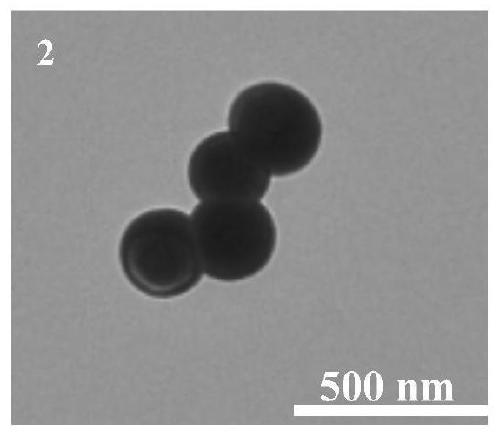

[0035] As introduced in the background art, the current preparation method of core-shell silica particles is complicated and costly. Therefore, one of the objectives of the present invention is to provide a method for synthesizing silica spherical nanoparticles with a core-shell structure without using a microemulsion of a surfactant, which is simple, efficient and environmentally friendly. The preparation method of silica nano-spherical particles with core-shell structure comprises:

[0036] (1) Preparation of O / W type diethyl malonate / ethanol / water surfactant-free microemulsion: Diethyl malonate, ethanol and water are formulated into a clear and transparent microemulsion according to a certain ratio;

[0037] (2) O / W diethyl malonate / ethanol / water surfactant-free microemulsion, under magnetic stirring, add TEOS and APTES, and they will dissolve in the oil core to form a reactive microenvironment. Then, ammonia water is added as a catalyst, and the reactants condense to form...

Embodiment 1

[0053] (1) Preparation of O / W type surfactant-free microemulsion: In the reaction flask, add 4.0g ultrapure water and 36.0g ethanol, add 2.6g diethyl malonate under the action of magnetic stirring, keep stirring at room temperature for 30min , until the solution is mixed.

[0054] (2) Preparation of solid silica nanoparticles

[0055] Add 1 mL tetraethyl orthosilicate to the microemulsion, then add 0.4 mL APTES ethanol solution, maintaining magnetic stirring. Both substances are completely dissolved in the oil nucleus.

[0056] (3) The reaction flask was placed in an ice-water bath for 2 h with magnetic stirring, then 1.5 mL of ammonia water (25% wt) was added, and after being kept in the ice-water bath for 30 minutes, the reaction was changed to room temperature for 60 h with magnetic stirring.

[0057] (4) After the reaction, centrifuge to obtain a white precipitate, which is washed twice with water and ethanol. After obtaining the white powder, put it in an oven at 60°C ...

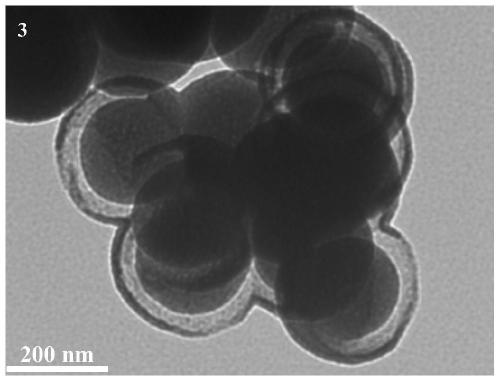

Embodiment 2

[0059] Dissolve an appropriate amount of white powder prepared in Example 1 in ultrapure water at 40°C, keep the temperature at a constant temperature for 144 hours, then centrifuge, wash once with water and ethanol to obtain a white solid, and place it in an oven at 60°C for 12 hours. Save for testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com