Anti-fog spray and preparation method thereof

An anti-fogging agent and spray technology, applied in the field of anti-fogging spray and its preparation, can solve the problems of lack of lubrication and anti-static, anti-corrosion and anti-bacterial, unable to meet the needs of automobile use, single performance of glass anti-fogging agent, etc. The effect of maintaining glass transparency, not easy to absorb dust, and good anti-fog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

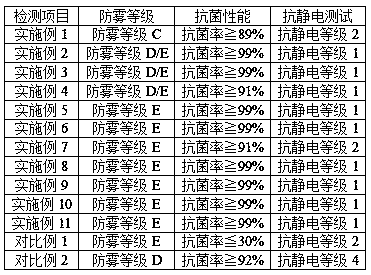

Embodiment 1

[0025] An anti-fog spray, comprising by mass fraction, anti-fog agent: fatty alcohol polyoxyethylene ether sodium sulfate 1%, antibacterial agent: polyhexamethylene biguanide hydrochloride 0.5%, antistatic agent: N-ten Hexaalkylpyridine nitrate 1%, stabilizer: modified acrylic acid polymer 0.5%, solvent A: ethanol 10%, solvent B: water 87%.

[0026] A kind of preparation method of anti-fog spray, first mix anti-fog agent, antibacterial agent and dehydrated alcohol, stir 1000rpm, 5min, obtain mixture A; antistatic agent and part of water are mixed, stir 1000rpm, 3min, obtain mixture B ; Stir the remaining water at 800rpm, slowly add mixture A and mixture B to it, while maintaining a water temperature of 50°C, and add the stabilizer drop by drop until it becomes a transparent liquid, which is a new type of antibacterial antistatic anti-fog spray.

Embodiment 2

[0028] An anti-fog spray, including by mass fraction, anti-fog agent: fatty alcohol polyoxyethylene ether 1%, antibacterial agent: polyhexamethylene biguanide hydrochloride 1%, antistatic agent: N-hexadecane Base pyridine nitrate 1.5%, stabilizer: modified acrylic acid polymer 1.5%, solvent A: ethanol 10%, solvent B: water 85%.

[0029] A kind of preparation method of anti-fog spray, first mix anti-fog agent, antibacterial agent and dehydrated alcohol, stir 1000rpm, 5min, obtain mixture A; antistatic agent and part of water are mixed, stir 1000rpm, 3min, obtain mixture B ; Stir the remaining water at 800rpm, slowly add mixture A and mixture B to it, while maintaining a water temperature of 50°C, and add the stabilizer drop by drop until it becomes a transparent liquid, which is a new type of antibacterial antistatic anti-fog spray.

Embodiment 3

[0031] An anti-fog spray, comprising by mass fraction, anti-fog agent: fatty alcohol polyoxyethylene ether 1%, antibacterial agent: polyhexamethylene biguanide hydrochloride 2%, antistatic agent: N-hexadecane Base pyridine nitrate 2%, stabilizer: modified acrylic acid polymer 2%, solvent A: ethanol 10%, solvent B: water 83%.

[0032] A kind of preparation method of anti-fog spray, first mix anti-fog agent, antibacterial agent and dehydrated alcohol, stir 1000rpm, 5min, obtain mixture A; antistatic agent and part of water are mixed, stir 1000rpm, 3min, obtain mixture B ; Stir the remaining water at 800rpm, slowly add mixture A and mixture B to it, while maintaining a water temperature of 50°C, and add the stabilizer drop by drop until it becomes a transparent liquid, which is a new type of antibacterial antistatic anti-fog spray.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com