VOC treatment device and method using fuel machine

A processing device and fuel engine technology, applied in the direction of gaseous fuel pretreatment, combustion methods, fuel supply, etc., can solve the problems of difficult governance, no recycling value, high one-time investment and high operating costs, and reduce energy consumption, The effect of avoiding energy loss and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

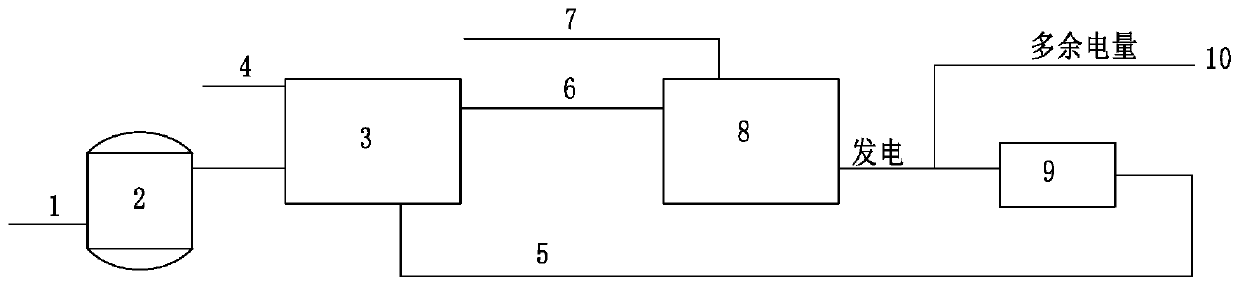

[0046] The present application provides a VOC treatment device using a fuel engine, including: a gas pretreatment unit, a gas combustion unit, and a gas distribution unit; the gas pretreatment unit mixes the VOC gas in proportion after the VOC gas is left still, and the gas The pretreatment unit includes: a gas main pipe 1, a buffer tank 2, and a gas distribution system 3; one end of the gas main pipe 1 is connected to the discharge port of the VOC gas, and the other end of the gas main pipe 1 is connected to the buffer tank 2 , VOC gas enters the buffer tank 2 through the gas main pipe 1, the VOC gas enters the buffer tank 2 for buffering, and the VOC gas with different contents is left to stand, and the buffered VOC gas is released after the buffer tank 2 reaches a certain pressure Enter the gas distribution system 3, the buffer tank 2 is connected with the gas distribution system 3 through a gas pipeline, the upper side of the gas distribution system 3 is provided with an in...

Embodiment 2

[0050] Basically consistent with the above-mentioned embodiment, the differences between this embodiment and the above-mentioned embodiment are:

[0051] Multiple fuel engines 8 are connected in parallel to burn VOC gas. Compared with one fuel engine 8, multiple fuel engines 8 can effectively improve the processing rate of VOC gas, and the power generation is also greatly improved.

[0052] The application also provides a VOC treatment method of an internal combustion engine, the method is as follows:

[0053] First, the VOC gas enters the buffer tank through the gas main pipe, and the VOC gas with different contents is left in the buffer tank. After the buffer tank reaches a certain pressure, the buffered VOC gas is released and enters the gas distribution system; the gas distribution system described by Ran Zhou The system transfers the VOC gas to the fuel engine according to the gas ratio, and the fuel engine generates electricity after fully burning the VOC gas. Finally, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com