Heating device and heating method of capillary tube chromatographic column

A capillary chromatographic column and heating device technology, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of high price, inaccurate temperature control, difficult loading and unloading, etc., and achieves the effects of simple production, simple production method and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1, the relationship between the temperature change of the capillary chromatographic column and its column pressure

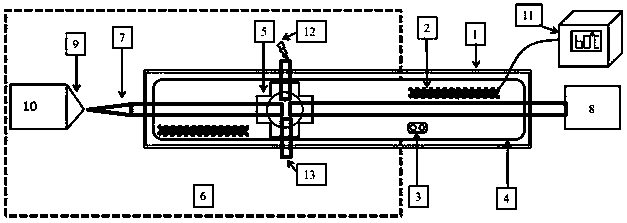

[0043] Such as figure 2 As shown, a capillary chromatographic column 7 with a size of 30 cm×150 μm and a spray head is used. The inner diameter of the spray head of the capillary chromatographic column 7 used is 150 μm, the particle size of the fully porous reversed-phase chromatography packing is 3 μm, and the pore size is 10 nm. A 30cm×150μm capillary chromatographic column 7 with a spray head is fixed in the liquid phase four-way card slot 5 in the capillary column thermostat 1 through a four-way piece. Such as figure 2 As shown in a), the nozzle end of the capillary chromatographic column 7 is directly above the atmospheric pressure inlet of the mass spectrometer 10 at 2 mm, figure 2In b), the required temperature of the column thermostat 1 can be set in the power supply and temperature controller 11, and the flat end of the capillary ...

Embodiment 2

[0048] Example 2. Application of the liquid mass spectrometry system equipped with the heating device of the present invention in complex sample analysis

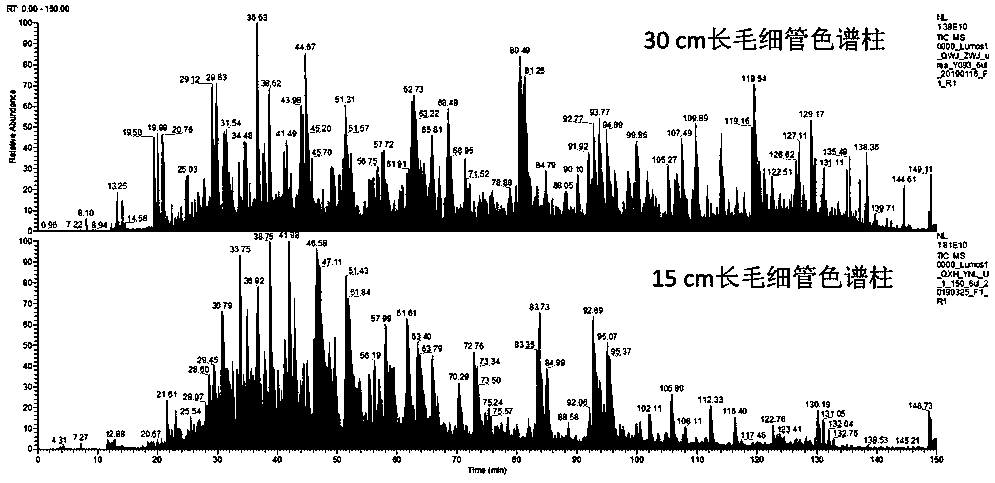

[0049] In order to further evaluate the performance of the heating device of the present invention, it is applied to the analysis of normal human urine proteome expression profile. On the LC-MS system equipped with the heating device of the present invention, perform the LC-MS analysis of the urine protease digest under the condition of 15cm and 30cm capillary chromatographic column length, and repeat the experiment once.

[0050] From image 3 As shown, due to the use of the ultra-long 150min chromatographic gradient, the separation efficiency is more obvious for the 30cm capillary column with a longer column length, and more peptide peaks can be separated after 100min, effectively increasing the number of spectral identifications. The data obtained by LC / MS analysis was searched by the maxquant search engine, and the ave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com