Gas diffusion layer for proton exchange film fuel cell and preparation method thereof, and proton exchange film fuel cell

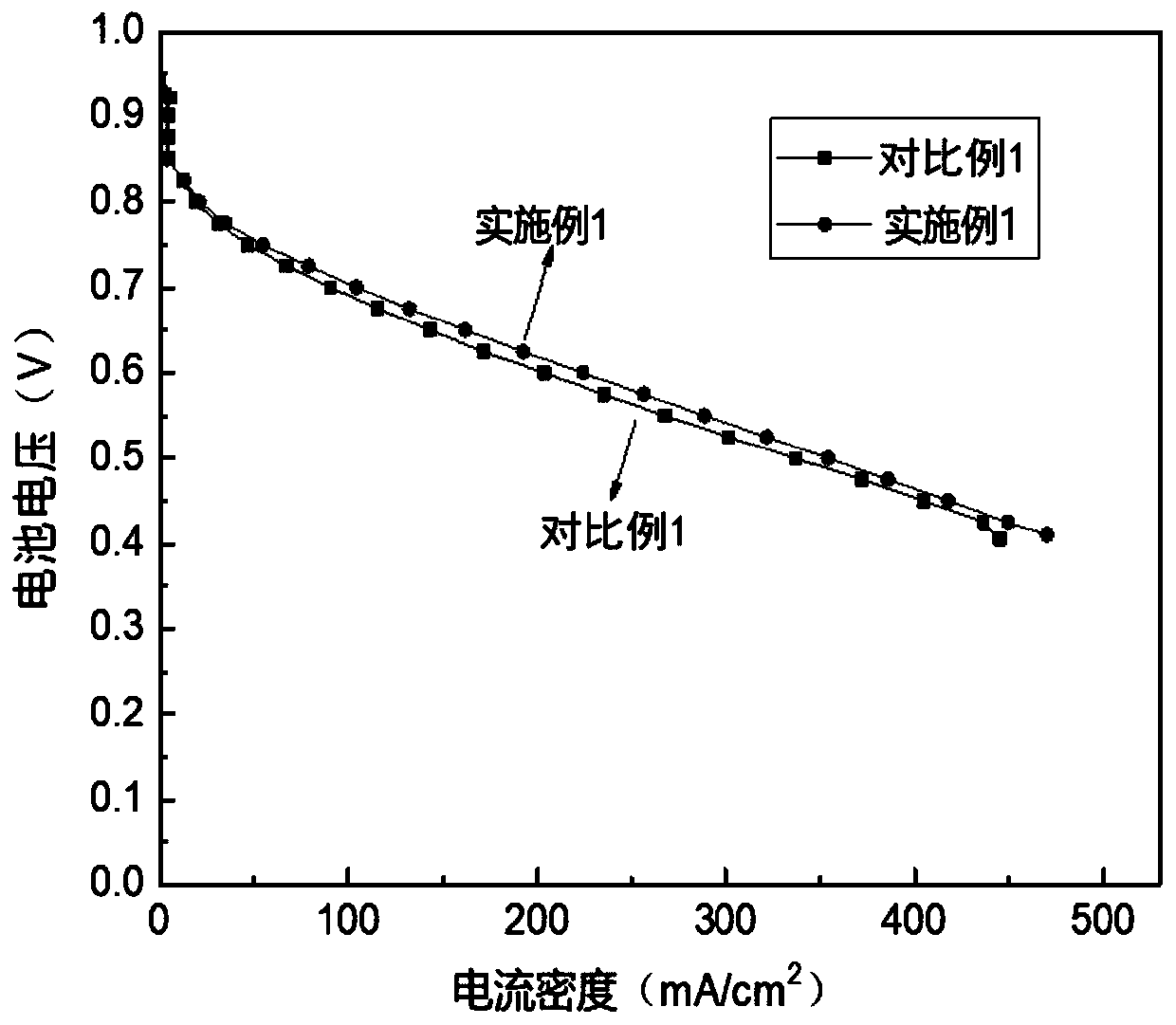

A proton exchange membrane and gas diffusion layer technology, applied in fuel cells, battery electrodes, electrical components, etc., can solve the problems of insufficient uniformity and smoothness of the microporous layer, leakage of slurry into the interior of the base layer, etc. The effect of eliminating sintering treatment and uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

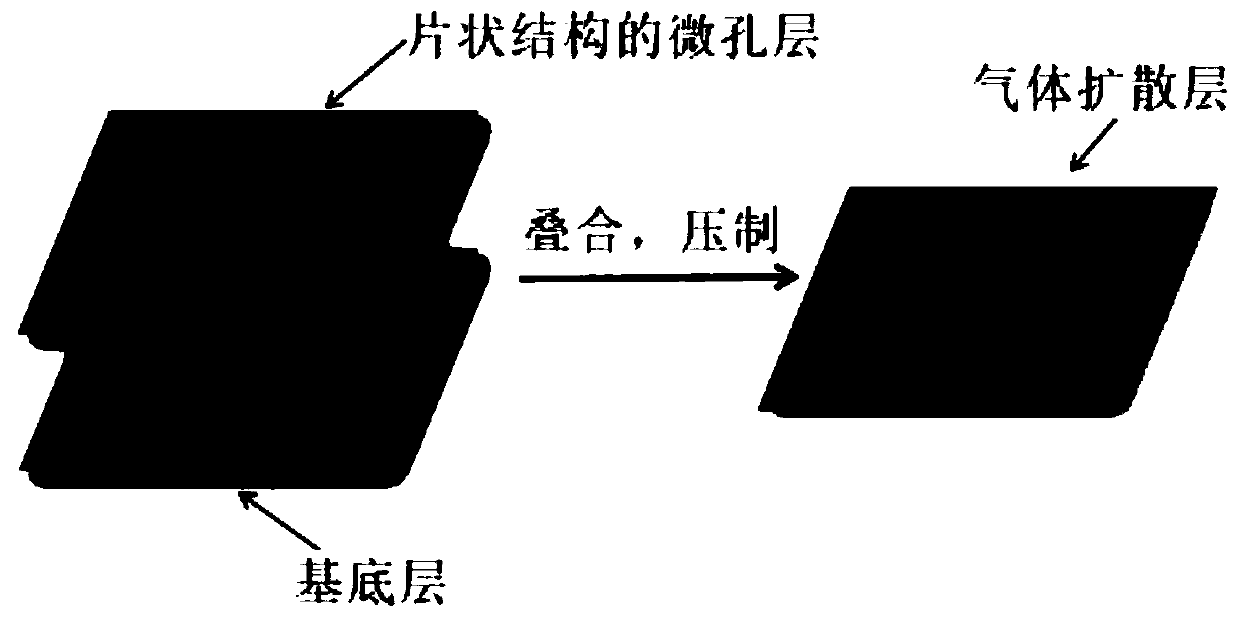

[0057] In this example, the preparation of the gas diffusion layer for the proton exchange membrane fuel cell is carried out.

[0058] First, the carbon fiber paper is completely immersed in 5wt% polytetrafluoroethylene (PTFE) emulsion, ultrasonically dispersed evenly, placed in an oven at a temperature of 75 ° C for 0.5h and weighed, repeating this step until the content of the PTFE emulsion in the carbon fiber paper It accounts for 5% of the total mass; the dried carbon fiber paper is placed in a muffle furnace, and sintered at a temperature of 375°C for 0.5h to obtain a hydrophobic treated base layer.

[0059] The PTFE emulsion (5wt%) of the Vulcan XC-72 carbon black of 20mg and 100mg is joined in 25mL dehydrated alcohol solvent, ultrasonic dispersion 1h to form uniform conductive carbon slurry; Conductive carbon slurry is placed in oven, in At 80°C, dry for 6 hours; add 2mL of absolute ethanol to the dried conductive carbon mixture for wetting, gather the conductive carbon...

Embodiment 2

[0062] In this example, the preparation of the gas diffusion layer for the proton exchange membrane fuel cell is carried out.

[0063] First, completely immerse the carbon fiber woven cloth into 5wt% polyvinylidene fluoride emulsion (PVDF) emulsion, ultrasonically disperse it evenly, dry it in an oven at 75°C for 0.5h and weigh it, repeat this step until the PVDF in the carbon fiber woven cloth The content of the emulsion accounts for 10% of the total mass; the dried carbon fiber weave is arranged in a muffle furnace, and sintered at a temperature of 375°C for 0.5h to obtain a hydrophobic treated base layer.

[0064] 20mg of graphene powder and 100mg of PVDF emulsion (5wt%) were added to 25mL of absolute ethanol solvent and ultrasonically dispersed for 1h to form a uniform conductive carbon slurry; the conductive carbon slurry was placed in an oven at a temperature of 90°C and dry for 5 hours; add 2 mL of absolute ethanol solvent to the dried conductive carbon mixture for wett...

Embodiment 3

[0067] In this example, the preparation of the gas diffusion layer for the proton exchange membrane fuel cell is carried out.

[0068] First, the porous wire mesh is completely immersed in 5wt% polypropylene (PP) emulsion, ultrasonically dispersed evenly, placed in an oven at a temperature of 75°C for 0.5h and weighed, repeating this step until the PTFE emulsion in the porous wire mesh The content of the content accounts for 15% of the total mass; the dried porous wire mesh is placed in a muffle furnace, and sintered at a temperature of 375°C for 0.5h to obtain a hydrophobic treated base layer.

[0069] Add 20mg of acetylene black carbon powder and 180mg of PP emulsion (5wt%) into 25mL of absolute ethanol solvent, ultrasonically disperse for 1h to form a uniform conductive carbon slurry, wherein the average particle size of acetylene black is 30-45nm, The specific surface area is 55~70m 2 / g; put the conductive carbon slurry in an oven, and dry it at 80°C for 6 hours; add 2mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com