Active energy ray-curable resin composition and coating agent

An active energy ray, curable resin technology, applied in coatings, polyurea/polyurethane coatings, instruments, etc., can solve the problems of not easy to curl, curing shrinkage of the coating film, easy curling of the cured coating film, etc., to achieve scratch resistance Excellent, excellent flexibility, both hardness and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4、 comparative example 1~4

[0257] [Manufacture of active energy ray curable resin composition]

[0258] In the urethane acrylate composition ([I], [I']) obtained above, 1-hydroxycyclohexyl phenone ( IGM company make, "Omnirad 184") 4 parts, and the active energy ray curable resin composition was obtained.

[0259] In addition, in Examples 3 and 4 and Comparative Examples 1 and 2, the obtained urethane acrylate compositions ([I], [I']) were diluted with ethyl acetate so that the resin component became 50%. , except the above, an active energy ray-curable resin composition was obtained in the same manner as above.

[0260] About the obtained active energy ray curable resin composition, the coating film (dry coating film) before hardening was formed as follows, and the tackiness of the coating film was evaluated. Then, a cured coating film was formed as shown below, and the hardness and flexibility of the cured coating film were evaluated. The evaluation results are shown in Table 1 below.

[0261] 〔Vi...

Embodiment 5~12、 comparative example 5~9

[0322] [Manufacture of active energy ray curable resin composition]

[0323] The above-obtained urethane acrylate compositions ([I], [II], [I']) were made into the compounding compositions shown in the following Table 2, and with respect to 100 parts of the curing components, added as light 4 parts of 1-hydroxycyclohexyl benzophenone (manufactured by IGM, "Omnirad 184") of a polymerization initiator (D) obtained the active energy ray curable resin composition.

[0324] About the obtained active energy ray curable resin composition, the cured coating film was formed as follows, and the hardness and flexibility of the cured coating film were evaluated. The evaluation results are shown in Table 2 below.

[0325] 〔Hardness of cured coating film〕

[0326] The active energy ray-curable resin composition obtained above was coated on an easily-adhesive PET film (manufactured by Toyobo Co., Ltd., "A4300", size 15 cm × 15 cm, thickness 125 μm) substrate using a coating bar, and the cu...

Synthetic example 1

[0367] [Synthesis Example 1: Urethane Acrylate Composition (III-1)]

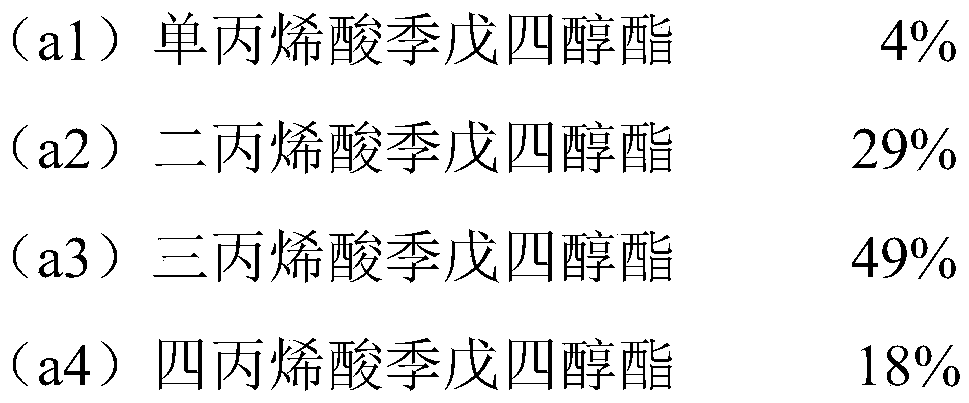

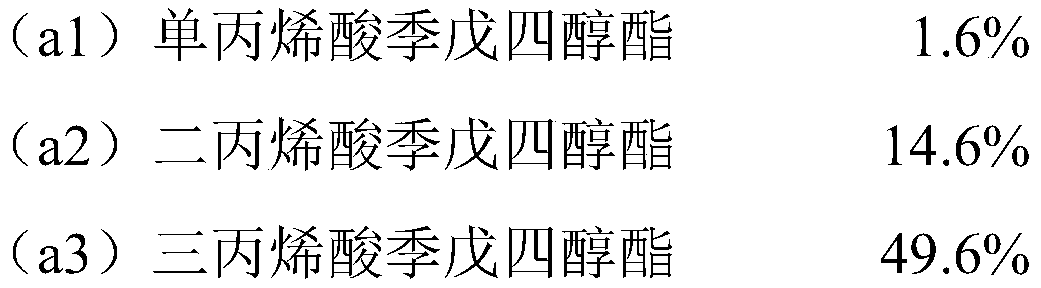

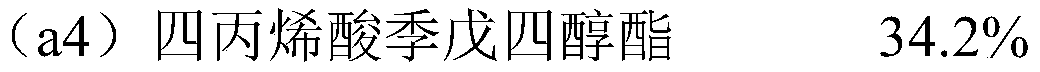

[0368] In a 4-neck flask equipped with a thermometer, a stirrer, a water-cooled condenser, and a nitrogen blowing inlet, 24 g of hydrogenated xylylene diisocyanate (C-2) and an acrylate mixture (A-1) with a hydroxyl value of 288 mgKOH / g were charged. (acrylic acid adduct of pentaerythritol) 33g, acrylate mixture (B-1) (acrylic acid adduct of dipentaerythritol) 43g of hydroxyl value 96mgKOH / g, ethyl acetate 100g as solvent, 4- 0.08 g of methoxyphenol and 0.05 g of dibutyltin dilaurate as a reaction catalyst were reacted at 60° C., and the reaction was terminated when the remaining isocyanate group reached 0.1%, to obtain a urethane acrylate composition (III -1) (resin component concentration 50%).

[0369] The weight average molecular weight of the obtained urethane acrylate composition (III-1) was 4900, and the viscosity at 20 degreeC was 40 mPa*s. In addition, the measurement of the viscosity in 20 degree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com