Catalyst for direct dehydrogenation preparation of ethanol to acetaldehyde and preparation method and application of catalyst

A catalyst and dehydrogenation technology, used in the preparation of dehydrogenation, physical/chemical process catalysts, carbon-based compound preparation, etc., can solve the problems of easy pulverization of catalysts, increase the difficulty of catalyst molding, reduce the mechanical strength of catalysts, etc., and achieve stability. Outstanding effect, excellent stability, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

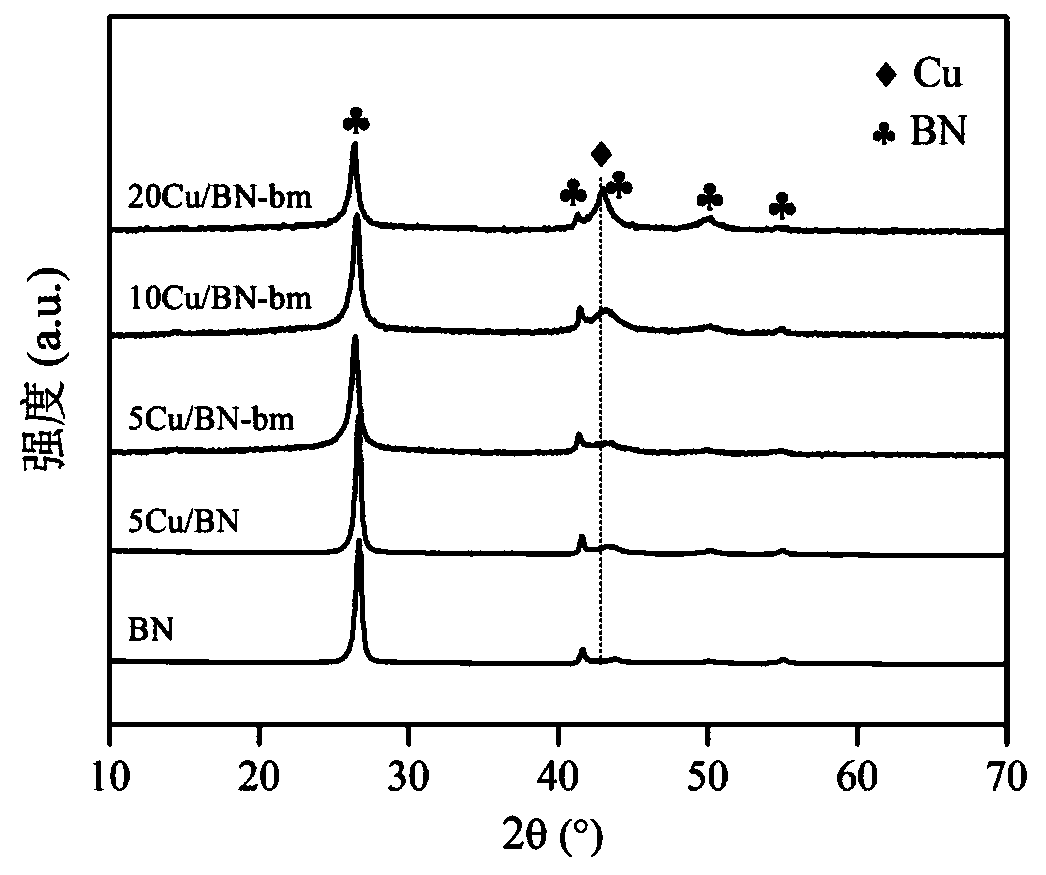

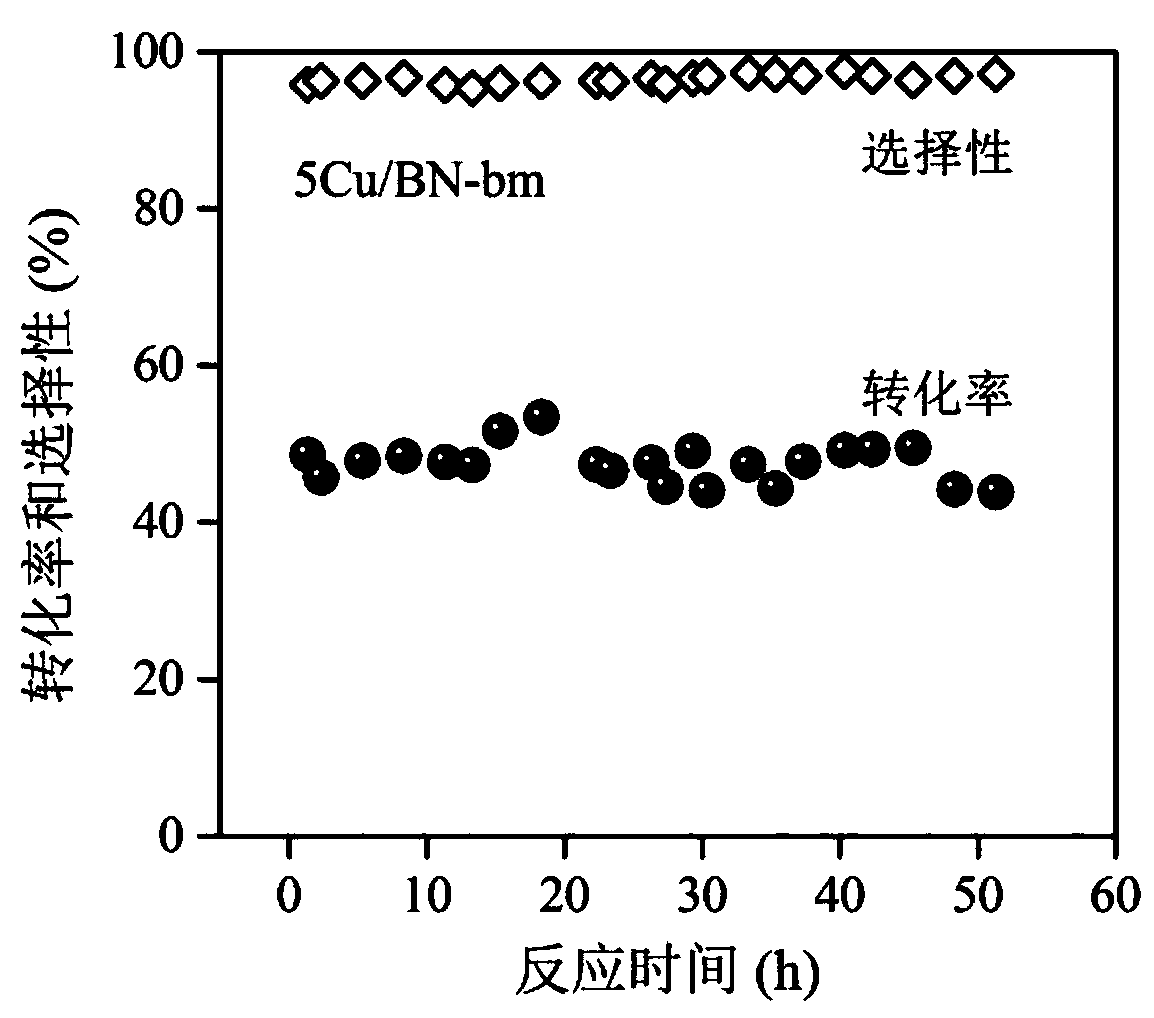

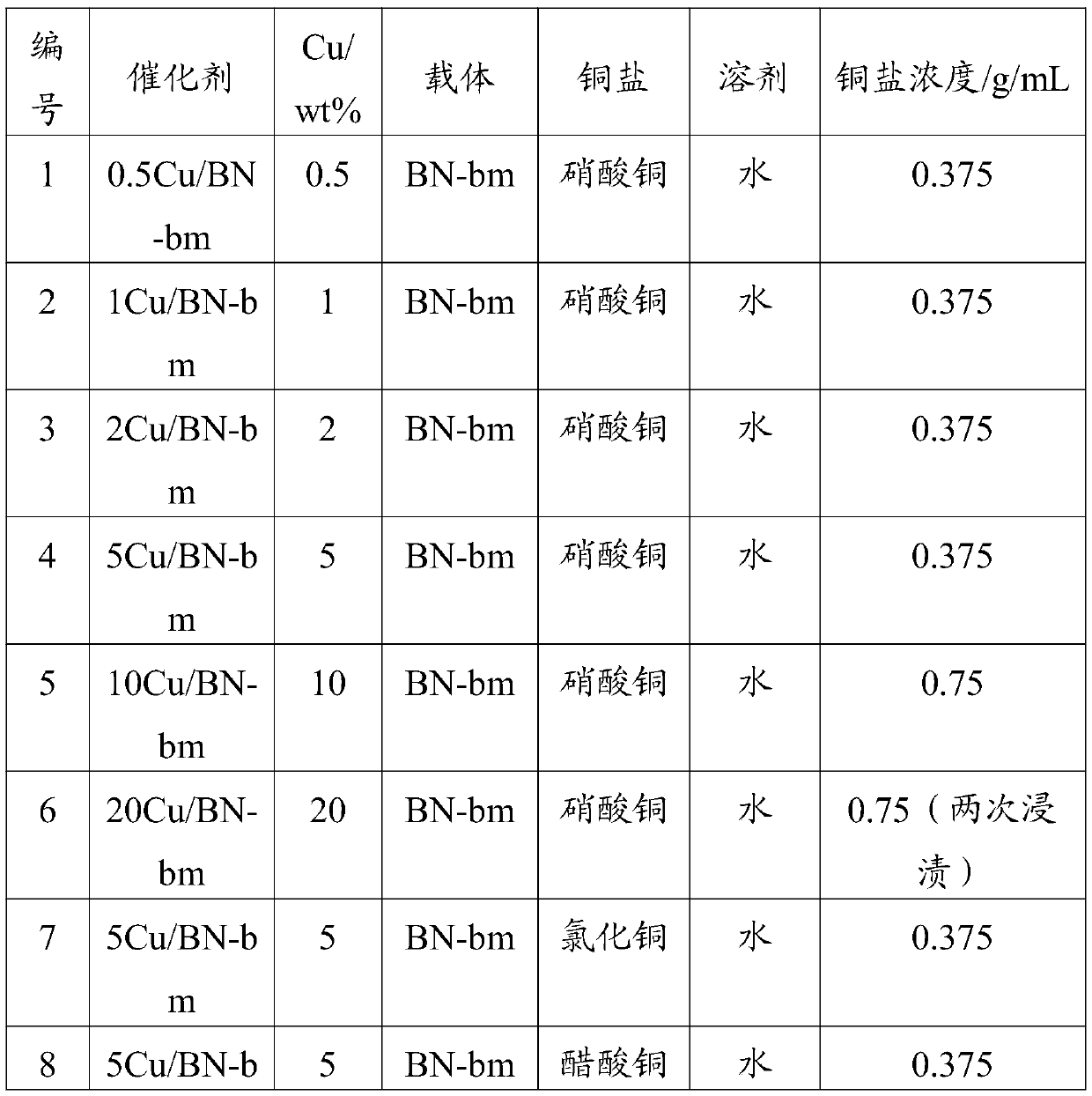

[0040] The preparation of embodiment 1 5Cu / BN-bm catalyst

[0041] Its preparation process is as follows:

[0042] (1) Take BN-bm and dry it in an airflow oven at 120°C for 2 hours to remove physically adsorbed water on the surface;

[0043] (2) At 25°C, take Cu(NO 3 ) 2 ·3H 2 Immerse an equal volume of O aqueous solution on the BN-bm obtained by step (1) drying, and let stand for 2h;

[0044] (3) drying the mixture after step (2) at 50° C. for 10 h to obtain a catalyst precursor;

[0045] (4) Dry the catalyst precursor obtained in step (3) at 140°C for 0.5h, then hydrogen reduce it at 350°C for 2h (10vol%H 2 / N 2 ), prepared 5Cu / BN-bm (No. 4 in Table 1) catalyst.

Embodiment 2

[0046] The preparation of embodiment 2 0.5Cu / BN-bm catalyst

[0047] Its preparation process is identical with embodiment 1, and difference is only to use the Cu(NO 3 ) 2 ·3H 2 O aqueous solution.

Embodiment 31

[0048] The preparation of embodiment 3 1Cu / BN-bm catalyst

[0049] Its preparation process is identical with embodiment 1, and difference is only to have used Cu(NO 3 ) 2 ·3H 2 O aqueous solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com