Waterproof and heat insulation dry powder mortar

A dry powder mortar and starch ether technology, applied in the field of building materials and construction, can solve the problems of reducing decoration process, less white decoration and waterproof and heat-insulating building materials, and achieve the effect of reducing decoration process, bright color and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

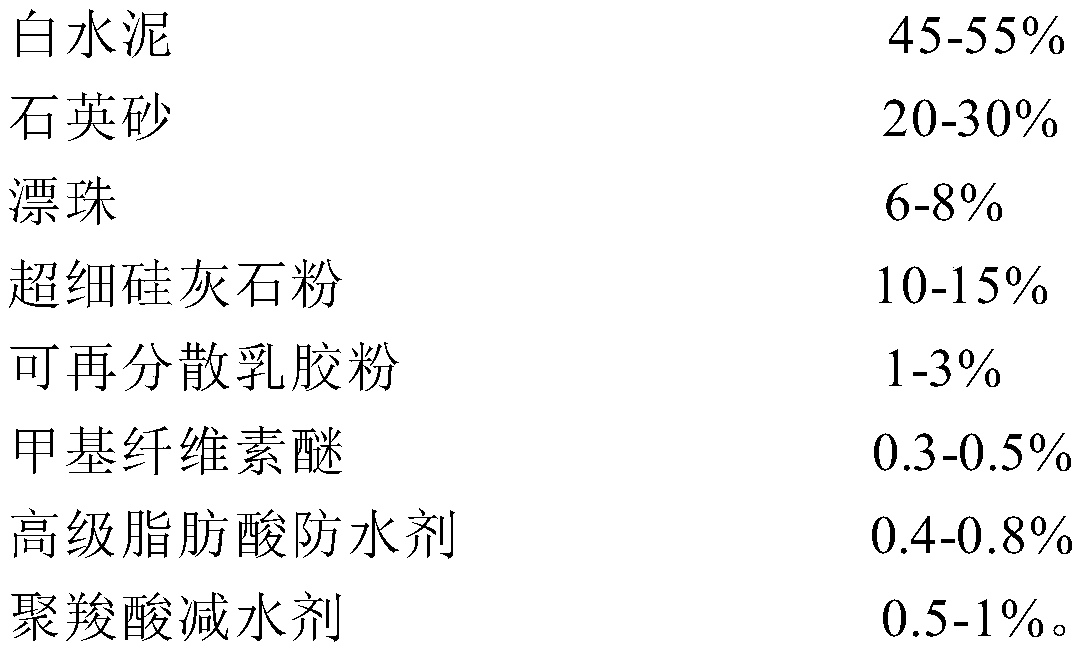

Embodiment 1

[0027] The waterproof and heat-insulating dry powder mortar of the present embodiment comprises by weight percentage: 45% white cement, 30% quartz sand, 6% floating beads, 14% superfine wollastonite powder, 2% redispersible latex powder, starch 0.3% ether, 0.3% methyl cellulose ether, 0.6% higher fatty acid water repellent, 0.8% polycarboxylate water reducer;

[0028] Among them, the strength grade of white cement is 525, the 28d compressive strength is 65.5MPa, and the whiteness is 89.0%;

[0029] The particle size of quartz sand is 40-200 mesh, the color is white or transparent, and the hardness is 7-8 on the Mohs scale. As a heavy filler, it has high strength, waterproof, fireproof, low temperature resistance, acid resistance, alkali resistance, wear resistance, etc. a function;

[0030] Floating beads are white spherical particles with a diameter of 50-850μm, a hardness of 6-7 on the Mohs scale, fine, hollow, light, and a true density of 2.10-2.20g / cm 3 , with excellent ...

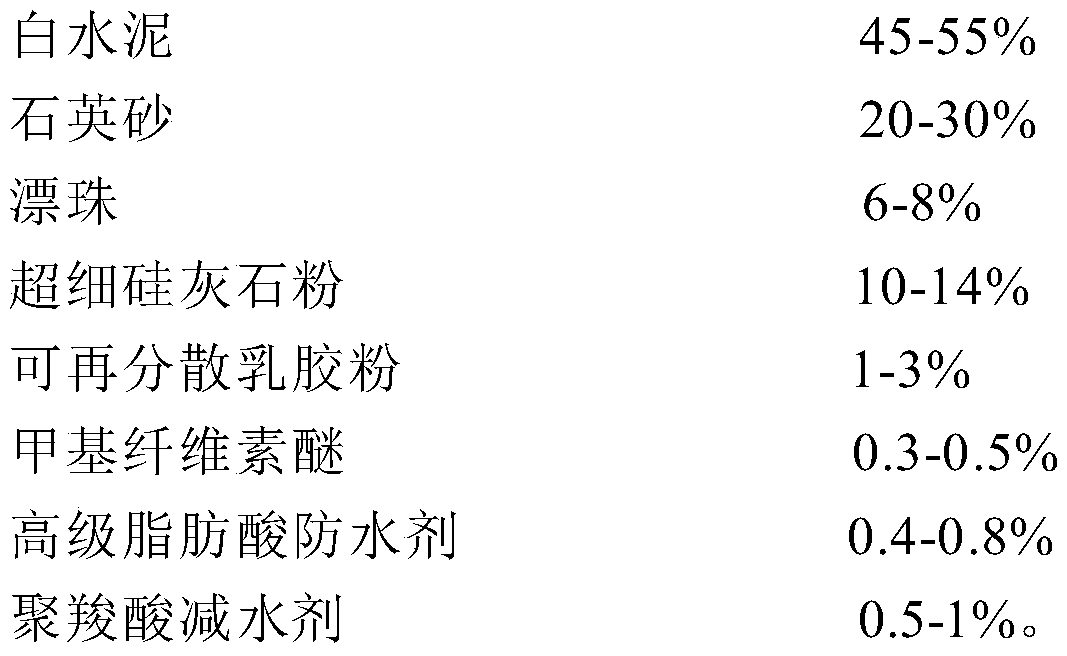

Embodiment 2

[0041] The waterproof and heat-insulating dry powder mortar of the present embodiment comprises by weight percentage: 50% of white cement, 26% of quartz sand, 6% of floating beads, 13.5% of superfine wollastonite powder, 2.5% of redispersible latex powder, and 0.5% based cellulose ether, 0.8% higher fatty acid water repellent, 0.7% polycarboxylate water reducer;

[0042] Among them, the strength grade of white cement is 525, the 28d compressive strength is 66MPa, and the whiteness is 90.0%;

[0043] The particle size of ultrafine wollastonite powder is 1250 mesh, whiteness ≥ 90.0%, glass luster, needle-like and fibrous crystal form, aspect ratio 10-20:1, refractive index 1.6-1.7;

[0044] Redispersible latex powder is acrylate, its glass transition temperature is -10℃, white powder;

[0045] The viscosity of methyl cellulose ether is 500cps, non-toxic and tasteless white powder;

[0046] All the other component materials are the same as in Example 1.

[0047] The preparatio...

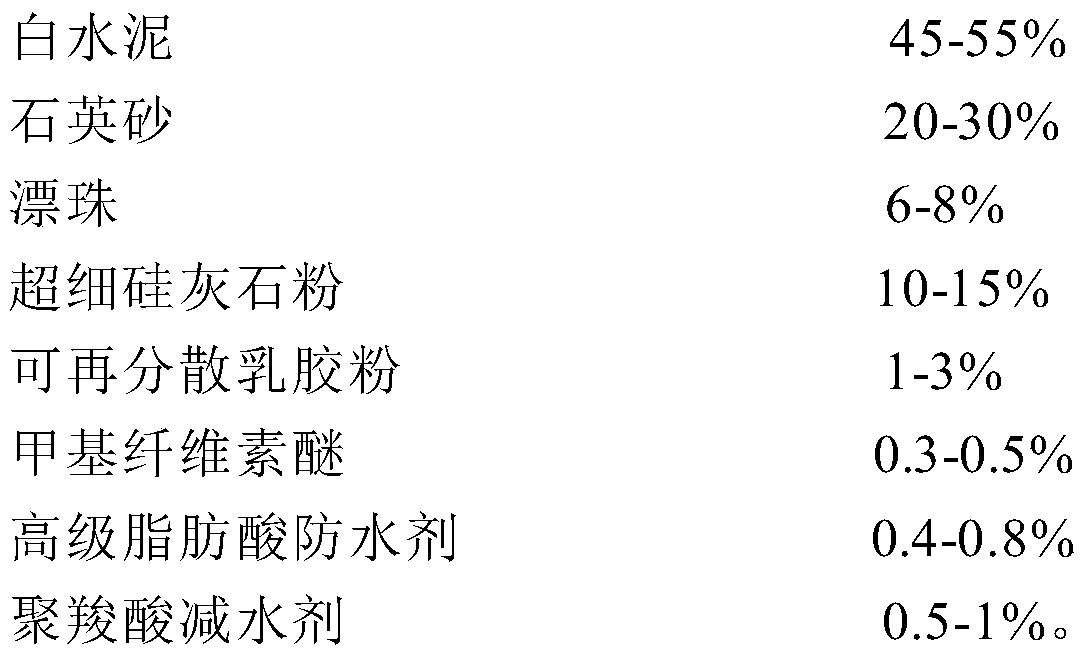

Embodiment 3

[0051] The waterproof and heat-insulating dry powder mortar of the present embodiment comprises: 50% of white cement, 26% of quartz sand, 8% of floating beads, 12.5% of superfine wollastonite powder, 1.5% of redispersible latex powder, starch 0.5% ether, 0.3% methyl cellulose ether, 0.7% higher fatty acid waterproofing agent, 0.5% polycarboxylate superplasticizer;

[0052] Among them, the strength grade of white cement is 525, the 28d compressive strength is 62MPa, and the whiteness is 89.0%;

[0053] Redispersible latex powder is a mixture of vinyl acetate and acrylate 1:1 (weight ratio), its glass transition temperature is -13°C, and it is in the form of white powder;

[0054] The viscosity of methyl cellulose ether is 300cps, it is non-toxic and tasteless white powder;

[0055] All the other component materials are the same as in Example 1.

[0056] The preparation method is the same as in Example 1, and the appearance of the prepared mortar is a white powdery mixture, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com