Silica-based ceramic core and preparation method thereof

A ceramic core and silicon-based technology, applied in the field of silicon-based ceramic cores and their preparation, can solve the problems of easy corrosion on the surface of castings, difficult to dissolve and remove, and high chemical stability, and achieve low sintering shrinkage and desorption. The effect of easy core and excellent high temperature bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 60 parts of quartz glass powder, 30 parts of zircon sand, and 10 parts of SiO2 additive according to the set ratio, mix them into a ball mill jar, add silica balls that are 1 / 2 of the total weight of raw materials, and ball mill for 2 hours;

[0038] Put the ball-milled mixed powder into a drying box and dry at 150°C for 2 hours;

[0039] Add 18% of the plasticizer of the total weight of the mixed powder into the slurry mixer and heat it to 120°C. After the plasticizer melts, take out the dried mixed powder, add it to the slurry mixer and stir at a constant speed for 30 hours, that is, the core The ingredients are prepared;

[0040] The mixed core ingredients are pressed and molded. The molding process is to hold the pressure for 20s under a pressure of 50MPa, and then demould to obtain a green body;

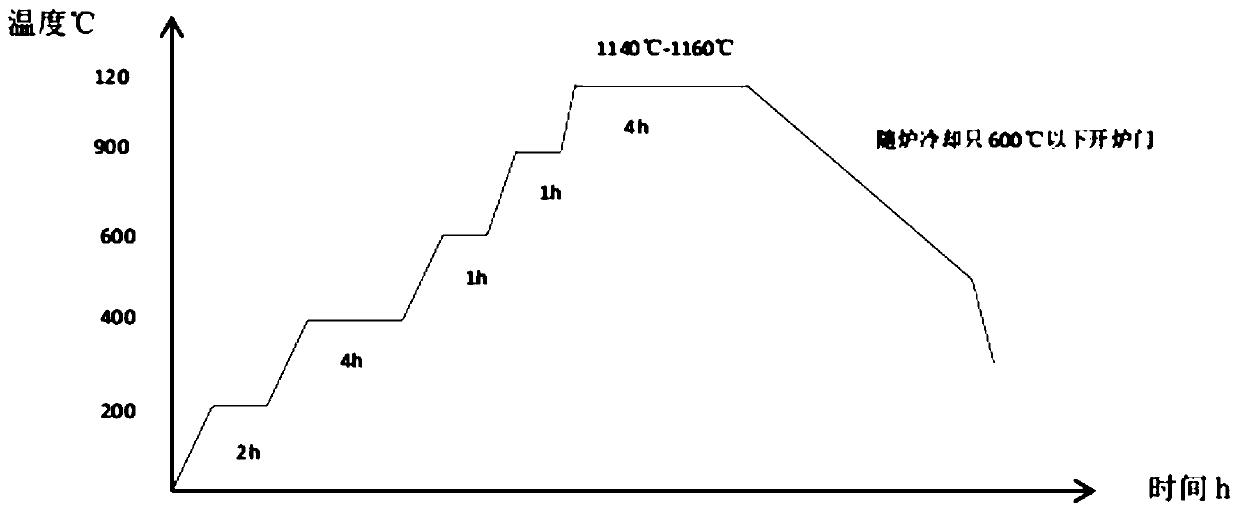

[0041] Embed the pressed green body sample into the calcined α-alumina filler, according to figure 1 Sintering was performed at the temperature settings shown;

...

Embodiment 2

[0045] Weigh 67 parts of quartz glass powder, 30 parts of zircon sand, and 3 parts of SiO2 additive according to the set ratio, mix them into a ball mill jar, add silica balls that are 1 / 2 of the total weight of raw materials, and ball mill for 2 hours;

[0046] Put the ball-milled mixed powder into a drying box and dry at 150°C for 2 hours;

[0047] Add 18% of the plasticizer of the total weight of the mixed powder into the slurry mixer and heat it to 120°C. After the plasticizer melts, take out the dried mixed powder, add it to the slurry mixer and stir at a constant speed for 30 hours, that is, the core The ingredients are prepared;

[0048] The mixed core ingredients are pressed and molded, and the molding process is to hold the pressure for 15s under a pressure of 60MPa, and then demould to obtain a green body;

[0049] Embed the pressed green body sample into the calcined α-alumina filler, according to figure 1 Sintering was performed at the temperature settings shown;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com