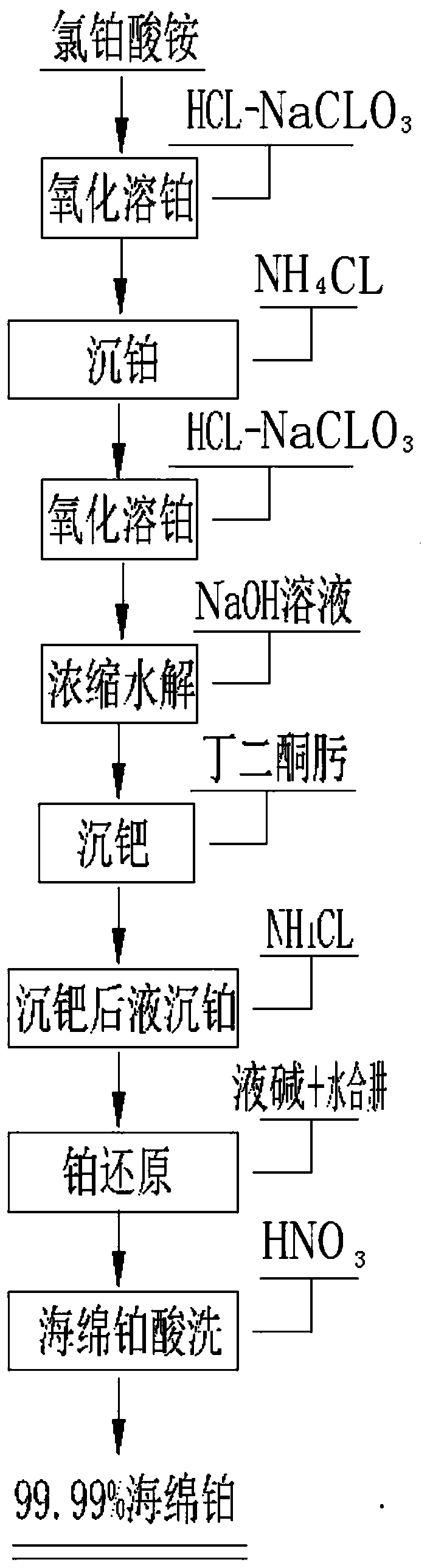

Process for separating and purifying spongy platinum from ammonium chloroplatinate

A technology of ammonium chloroplatinate and sponge platinum, which is applied in the field of separation and purification of platinum metal, can solve the problems of excessive palladium in sponge platinum, and achieve the effects of overcoming palladium exceeding the standard, short cycle time and wide material adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Weigh 500g of crude ammonium chloroplatinate solid, the mass fraction of ammonium chloroplatinate in the crude ammonium chloroplatinate is 92.6%, add 2L of water to slurry to obtain slurry, add hydrochloric acid to make the acidity reach 35g / L , heat the slurry to 93°C, add 200g of sodium chlorate while stirring, stir at constant temperature to completely dissolve the ammonium chloroplatinate solid, cool the solution to 60°C and filter;

[0044] (2) Heat the filtrate to a constant temperature of 95°C, add hydrochloric acid while stirring to catch chlorine, until no chlorine gas emerges, and the acidity reaches 3mol / L, the solution is cooled to 50°C, and 100g of ammonium chloride is added to precipitate platinum. Stir for 20 minutes, keep the stirring speed at 30 r / s, let it stand for clarification for 30 minutes, filter platinum yellow, wash with 3mol / L hydrochloric acid, 50g / L ammonium chloride mixture until the washing liquid is clear;

[0045] (3) Slurry the obta...

Embodiment 2

[0051] (1) Weigh 500g of crude ammonium chloroplatinate solid, the mass fraction of ammonium chloroplatinate in the crude ammonium chloroplatinate is 48.36%, add 2L of water to slurry to obtain a slurry, add hydrochloric acid to make the acidity reach 35g / L , heat the slurry to 93°C, add 150g of sodium chlorate while stirring, stir at constant temperature to completely dissolve the ammonium chloroplatinate solid, cool the solution to 60°C and filter;

[0052] (2) Heat the filtrate to a constant temperature of 95°C, add hydrochloric acid while stirring to catch chlorine, until no chlorine gas emerges, and the acidity reaches 3mol / L, the solution is cooled to 50°C, and 80g of ammonium chloride is added to precipitate platinum. Stir for 20 minutes, keep the stirring speed at 30 r / s, let it stand for clarification for 30 minutes, filter platinum yellow, wash with 3mol / L hydrochloric acid, 50g / L ammonium chloride mixture until the washing liquid is clear;

[0053] (3) Slurry the ob...

Embodiment 3

[0059] (1) Weigh 500g of crude ammonium chloroplatinate solid, the mass fraction of ammonium chloroplatinate in the crude ammonium chloroplatinate is 12.31%, add 2L of water to slurry to obtain a slurry, add hydrochloric acid to make the acidity reach 35g / L , heat the slurry to 93°C, add 35g of sodium chlorate while stirring, stir at constant temperature to completely dissolve the ammonium chloroplatinate solid, cool the solution to 60°C and filter;

[0060] (2) Heat the filtrate to a constant temperature of 95°C, add hydrochloric acid while stirring to catch chlorine, until no chlorine gas emerges, and the acidity reaches 3mol / L, the solution is cooled to 50°C, and 20g of ammonium chloride is added to precipitate platinum. Stir for 20 minutes, keep the stirring speed at 30 r / s, let it stand for clarification for 30 minutes, filter platinum yellow, wash with 3mol / L hydrochloric acid, 50g / L ammonium chloride mixture until the washing liquid is clear;

[0061] (3) Slurry the obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com