A kind of liquid crystal polymer organogel and preparation method thereof

A technology of liquid crystal polymers and organogels, applied in the field of supramolecular materials, can solve the problems of poor mechanical strength of organogels, and achieve the effects of controllable structure, simple preparation method, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a method for preparing the liquid crystal polymer organogel, comprising the steps of:

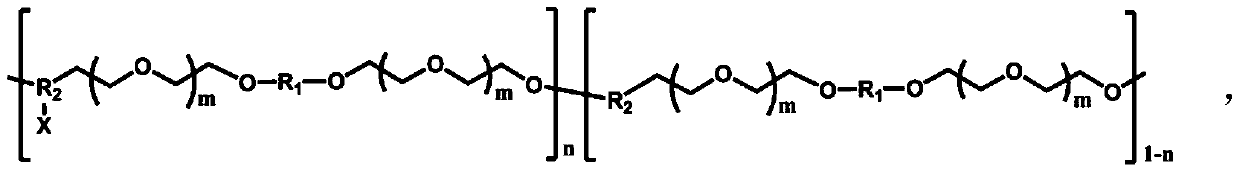

[0044] (1) Synthetic gel factor; the gel factor is a main chain type liquid crystal polymer gel factor, and the main chain type liquid crystal polymer is a polymer formed by polymerization of one or more main chain type liquid crystal polymer units ; Any one of the main chain type liquid crystal polymer units includes C 4 ~C 14 Alkoxy chains, rigid groups and linking groups;

[0045] (2) Mix the gel factor obtained in step (1) with an organic solvent, and then raise the temperature to completely dissolve the gel factor, for example, to 50-100° C. to obtain an organic solution of the main chain type liquid crystal polymer;

[0046] (3) Lower the temperature of the main chain type liquid crystal polymer organic solution prepared in step (2) to obtain a polymer organogel, for example, the polymer organogel can be obtained by lowering the temperature...

Embodiment 1

[0058] The polymer organogel in this embodiment includes 8wt% liquid crystal polymer gel factor and 92wt% dioxane; wherein, the structure of the liquid crystal polymer gel factor is:

[0059]

[0060] The preparation method of this polymer organogel is as follows:

[0061] (1) Add 65.40 grams (470 mmol) K 2 CO 3 (Na 2 CO 3 ) and 10.81 grams (47mmol) Stir for half an hour. Then add 23.70 g (141 mmol) and 0.30 g (0.3 wt%) potassium iodide (sodium iodide can also be used), heated to 120 ° C, and reacted for 50 hours. After the reaction was stopped, it was cooled to room temperature, filtered, and rotary evaporated. Extracted three times with water and dichloromethane, separated and subjected to column chromatography. The selection and ratio of column chromatography solvents are dichloromethane:n-hexane=1:3. After spin-drying the solvent, put it in a vacuum oven for 24 hours. Recrystallized in chloroform and filtered to obtain

[0062] Adjust the temperature of t...

Embodiment 2

[0067] The polymer organogel in this embodiment includes 8wt% liquid crystal polymer gel factor and 92wt% DMF; wherein, the structure of the liquid crystal polymer gel factor is:

[0068]

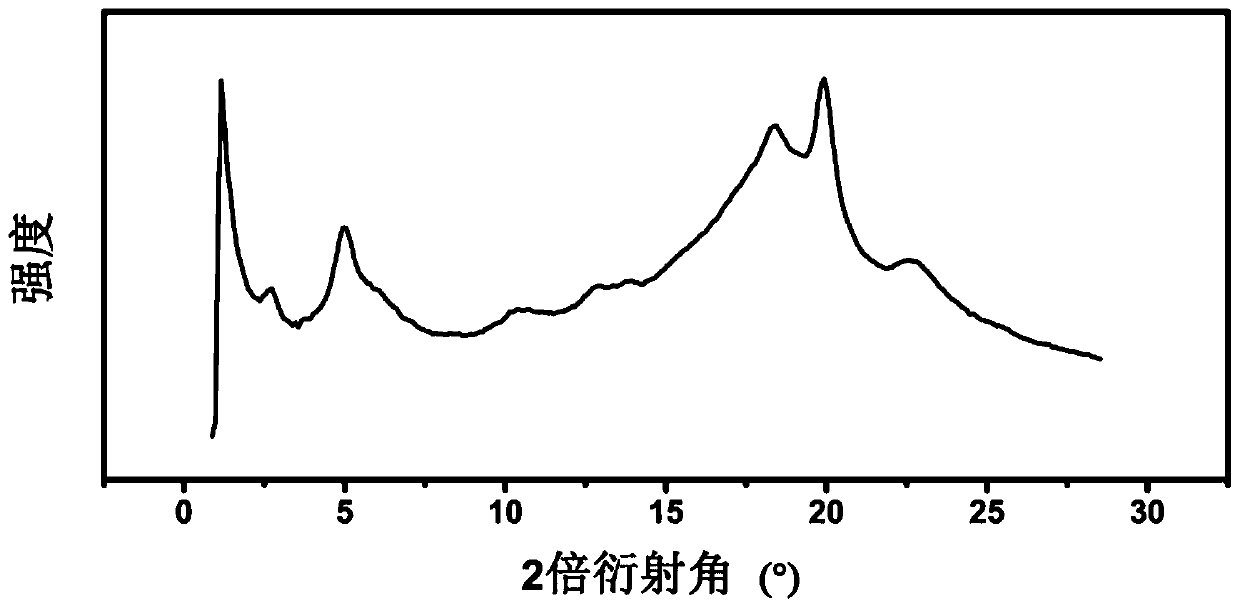

[0069] figure 1 It is the wide-angle X-ray diffraction pattern of the gel factor obtained in this embodiment. The preparation method of this polymer organogel is as follows:

[0070] (1) Add 65.40 grams (470 mmol) K 2 CO 3 and 8.74 g (47 mmol) Stir for half an hour. Then add 29.8 grams (141mmol) And 0.31 grams (0.3wt%) potassium iodide, heated to 100 ℃, reacted for 24 hours. After the reaction was stopped, it was cooled to room temperature, filtered, and rotary evaporated. Extracted three times with water and dichloromethane, separated and subjected to column chromatography. The selection and ratio of column chromatography solvents are dichloromethane:n-hexane=1:5. After spin-drying the solvent, put it in a vacuum oven for 24 hours. Recrystallized in chloroform and filtered t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com