Novel liquid crystal vertical alignment agent and preparation method and application thereof

A vertical alignment, liquid crystal technology, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of cumbersome coating process of PI alignment film, weak anchoring ability of liquid crystal molecules, affecting the performance of liquid crystal medium, etc., and achieve low temperature work effect. Excellent, excellent performance, high optical anisotropy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

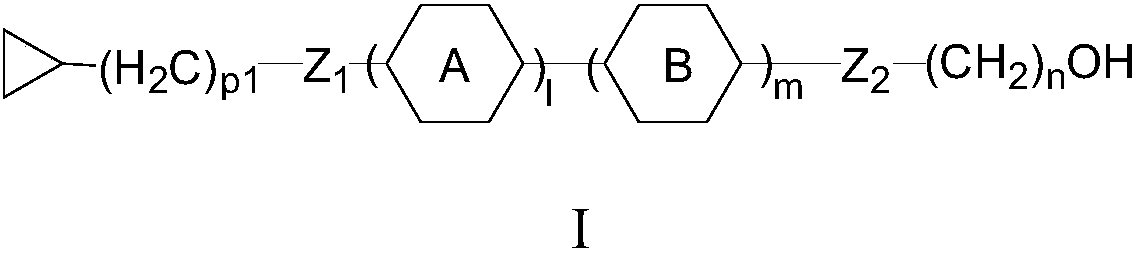

[0076] The structural formula of the vertical alignment agent is:

[0077]

[0078] The synthetic route for preparing compound BYLC-01 is as follows:

[0079]

[0080] Specific steps are as follows:

[0081] (1) Synthesis of compound BYLC-01-1:

[0082] Under nitrogen protection, add 33.0g compound 4-methyl ether phenylboronic acid, 42.2g 1-bromo-4-(cyclopropylmethylene)benzene, 200ml N,N-dimethylformamide, 100ml deionized Water, 41.4g anhydrous potassium carbonate, 0.5g tetrakistriphenylphosphine palladium, heated to 70°C for 3 hours. After conventional post-processing, chromatographic purification, eluting with n-hexane, and recrystallization from ethanol gave 43.2 g of a white solid (compound BYLC-01-1), GC: 99.6%, yield: 85.8%.

[0083] (2) Synthesis of compound BYLC-01:

[0084] Add 43.2g of compound BYLC-01-1, 400ml of dichloromethane to the reaction flask, cool down to -10°C, and add 220ml (0.22mol) of 1M boron tribromide in hexane dropwise at -10 to 0°C solu...

Embodiment 2

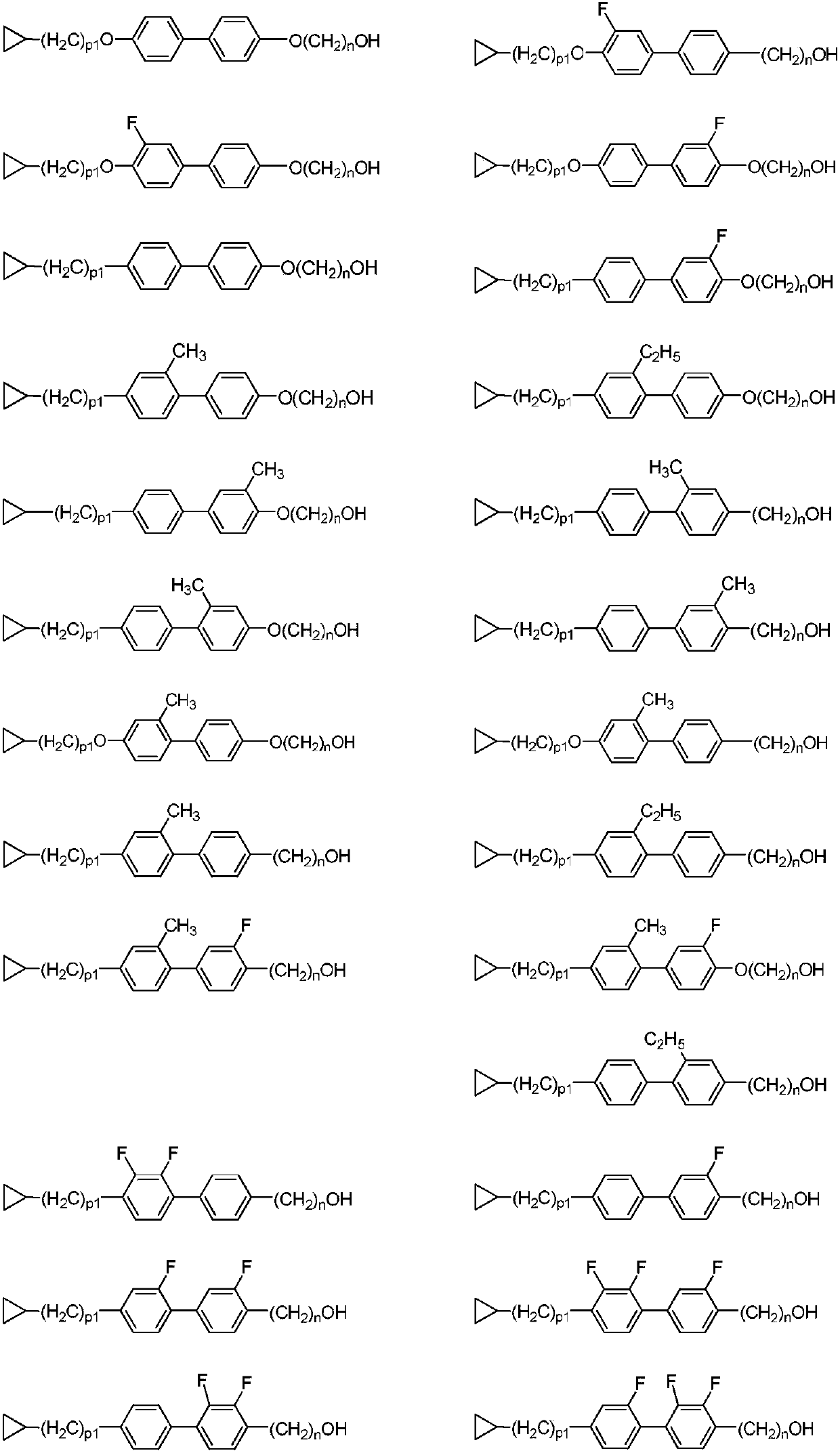

[0088] According to the technical scheme of Example 1, the following compounds can be synthesized by simply replacing the corresponding raw materials without changing any substantive operations:

[0089]

[0090]

[0091] Among them, p 1 means 0, 1 or 2; n means 0, 1, 2, 3, 4 or 5.

Embodiment 3

[0093] The structural formula of the liquid crystal compound is:

[0094]

[0095] The synthetic route for preparing compound BYLC-02 is as follows:

[0096]

[0097] Specific steps are as follows:

[0098] (1) Synthesis of compound BYLC-02-1:

[0099] Add 40.2g of p-bromoanisole and 450ml of tetrahydrofuran to the reaction flask, add 0.26mol of n-butyl lithium in n-hexane solution dropwise at -70~-80℃, and react for 1 hour under temperature control, and control the temperature at -70~- A solution consisting of 28.8g of 4-(cyclopropylmethylene)cyclohexanone and 90ml of tetrahydrofuran was added dropwise at 80°C, then naturally warmed to -30°C, 500ml of 2M hydrochloric acid aqueous solution was added for acidification, and conventional post-treatment was performed to obtain shallow Yellow liquid (compound BYLC-02-1) 49.6g, GC: 95.6% (cis + trans), yield: 95.4%.

[0100] (2) Synthesis of compound BYLC-02-2:

[0101] Add 49.6g of compound BYLC-02-1, 0.65g of p-toluenesu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com