Method for preparing nanoporous silver by electrodeposition

A technology of nanoporous silver and electrodeposition method, which is applied in the direction of electroforming nanostructure, nanotechnology, electroforming, etc., can solve the problems of gaps in performance and application fields, and can not be obtained, and achieve the effect of expanding performance and application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

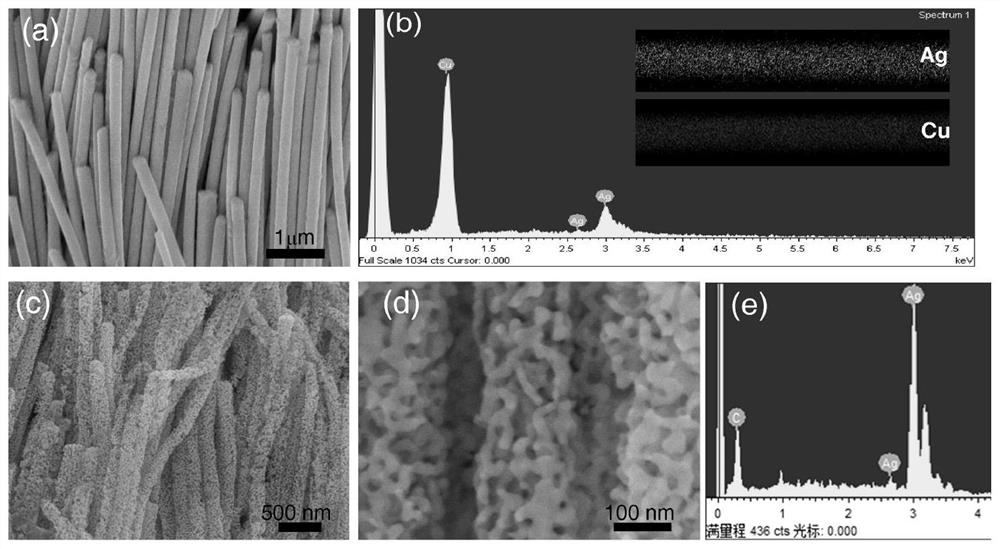

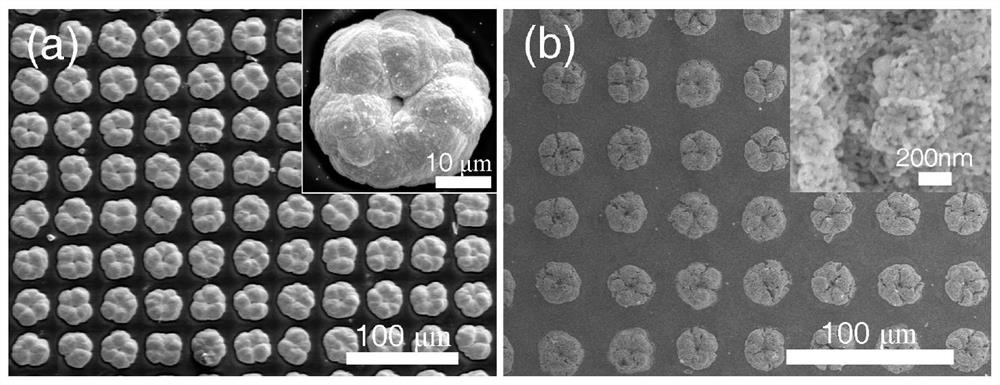

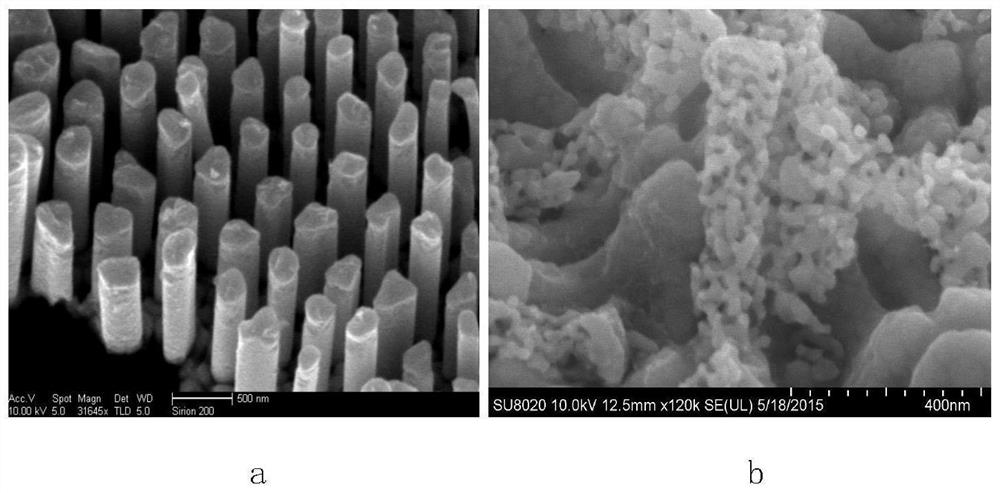

[0040] The concrete steps of preparation are:

[0041] Step 1, according to the volume ratio of the silver nitrate solution of 20mmol / L and the potassium iodide solution of 5mol / L is the ratio of 0.8:1, the silver nitrate solution is dripped in the potassium iodide solution and vigorously stirred, obtains [AgI 2 ] - complex solution.

[0042] Step 2, according to the volume ratio of the copper nitrate solution of 0.1mol / L, the sodium sulfite solution of 0.7mol / L and the potassium iodide solution of 3mol / L is the ratio of 0.3:0.7:1, mix the former two and drop in the potassium iodide solution and vigorously stirred to obtain [CuI 2 ] - complex solution.

[0043] Step 3, according to [AgI 2 ] - The complexation solution and [CuI 2 ] - The volume ratio of the complex solution is 0.8:1, and the two are mixed to obtain a complex mixed solution.

[0044] Step 4, with silver-silver chloride as the reference electrode, graphite sheet as the counter electrode, conductive subst...

Embodiment 2

[0048] The concrete steps of preparation are:

[0049] Step 1, according to the volume ratio of the silver nitrate solution of 25mmol / L and the potassium iodide solution of 4.5mol / L is the ratio of 0.98:1, the silver nitrate solution is dripped in the potassium iodide solution and vigorously stirred to obtain [AgI 2 ] - complex solution.

[0050] Step 2, according to the volume ratio of the copper nitrate solution of 0.15mol / L, the sodium sulfite solution of 0.65mol / L and the potassium iodide solution of 3.8mol / L is the ratio of 0.35:0.65:1, mix the former two and drop into the potassium iodide solution and vigorously stirred to obtain [CuI 2 ] - complex solution.

[0051] Step 3, according to [AgI 2 ] - The complexation solution and [CuI 2 ] - The volume ratio of the complex solution is 0.98:1, and the two are mixed to obtain a complex mixed solution.

[0052] Step 4, with silver-silver chloride as the reference electrode, the graphite sheet as the counter electrode,...

Embodiment 3

[0056] The concrete steps of preparation are:

[0057] Step 1, according to the volume ratio of the silver nitrate solution of 30mmol / L and the potassium iodide solution of 4mol / L is the ratio of 1.16:1, the silver nitrate solution is dripped in the potassium iodide solution and vigorously stirred, obtains [AgI 2 ] - complex solution.

[0058] Step 2, according to the volume ratio of the copper nitrate solution of 0.2mol / L, the sodium sulfite solution of 0.6mol / L and the potassium iodide solution of 4.5mol / L is the ratio of 0.4:0.6:1, mix the former two and drop into the potassium iodide solution and vigorously stirred to obtain [CuI 2 ] - complex solution.

[0059] Step 3, according to [AgI 2 ] - The complexation solution and [CuI 2 ] - The volume ratio of the complex solution is 1.16:1, and the two are mixed to obtain a complex mixed solution.

[0060] Step 4, with silver-silver chloride as the reference electrode, graphite sheet as the counter electrode, conductive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com